Method for continuously producing fibre reinforced synthetic resin lattice body

A synthetic resin and fiber-reinforced technology, applied in the direction of non-woven fabrics, building structures, building reinforcements, etc., can solve the problem of the quality reduction of grid-like bodies, hinder the full heating of grid-like bodies, and limit the speed of grid-like bodies And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The method of the present invention will be further described below according to the examples. However, it should be understood that the present invention is not limited by these Examples.

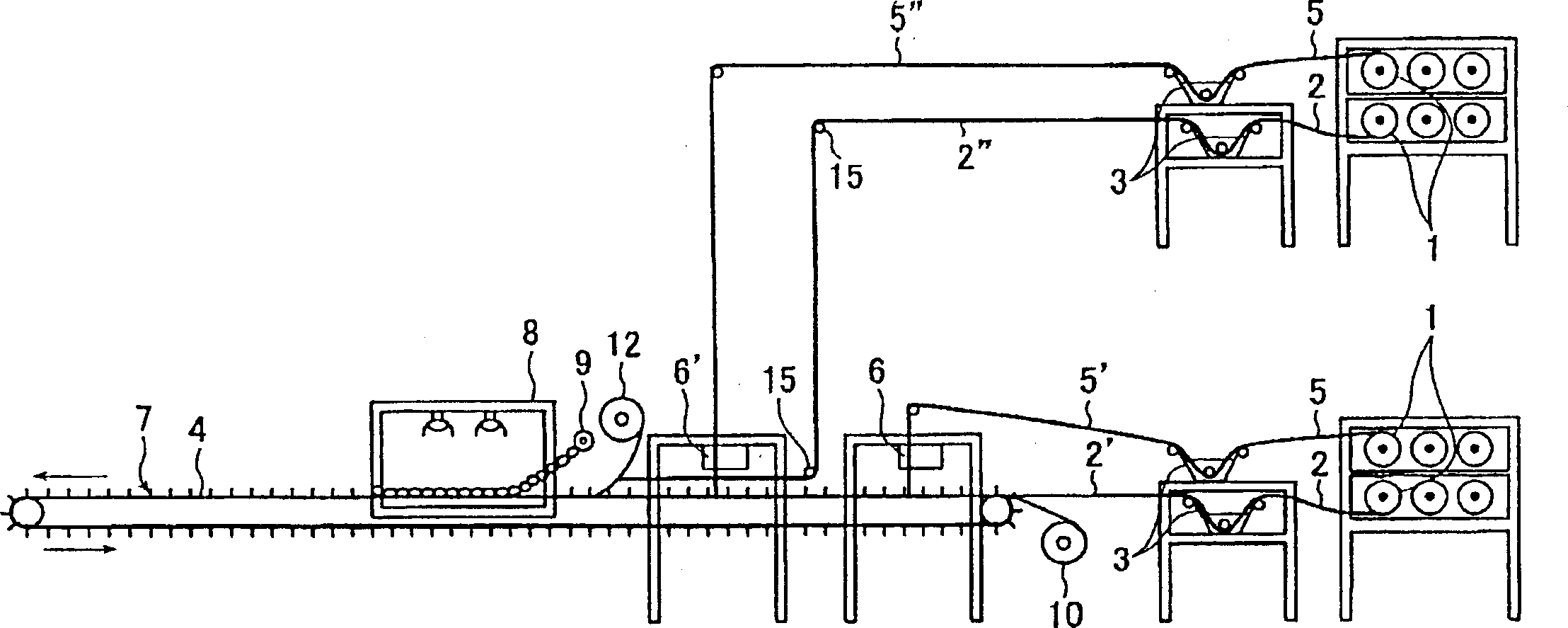

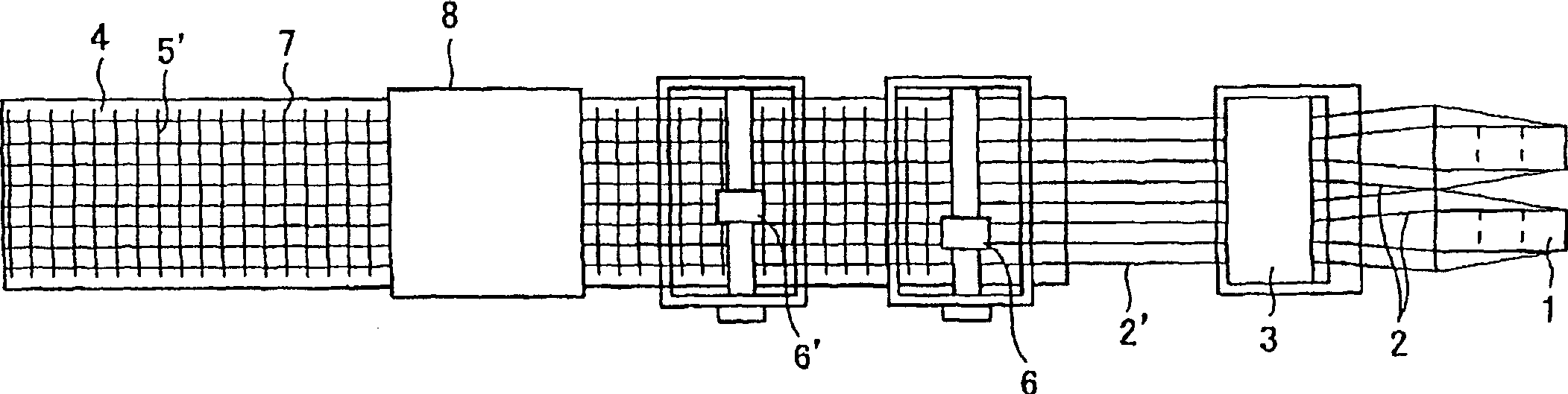

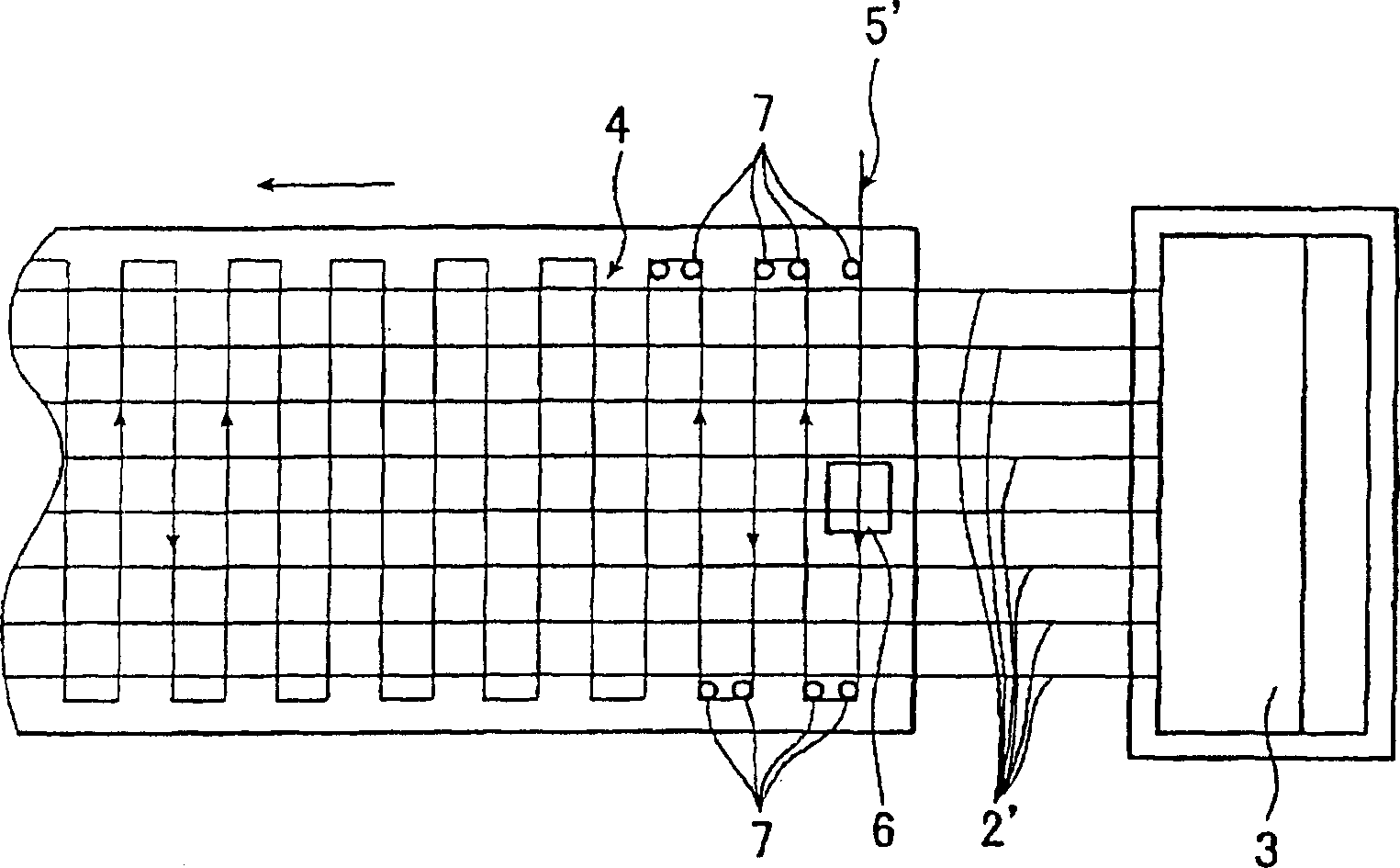

[0050] use figure 1 with figure 2 In the shown device, the heating and curing furnace adopts a far-infrared radiation furnace, and the carrier is a synthetic resin belt conveyor with a length of 40m and a width of 1.1m. Carbon fiber (monofilament, 6 μm in diameter) is used as the continuous fiber, and vinyl ester resin is used as the resin to continuously produce a fiber-reinforced synthetic resin mesh that is continuous in the length direction and can be used as a carbon-type concrete reinforcement equivalent to φ5 welding alloy. Body C4 (rib thickness 6mm, width 2mm, grid interval 50mm). From the strip-shaped grid body obtained in this way, 5 single-strand test pieces with a side length of 300mm were randomly cut from the vertical and horizontal components respectively, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com