Rivet, riveted joint structure, riveting apparatus and riveting method

A riveting structure and rivet technology, applied in rivets, connecting components, screws, etc., can solve the problems of large driving force and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below, refer to Figures 6A to 6C ,as well as Figure 7 A first embodiment of the first and second aspects of the present invention is described.

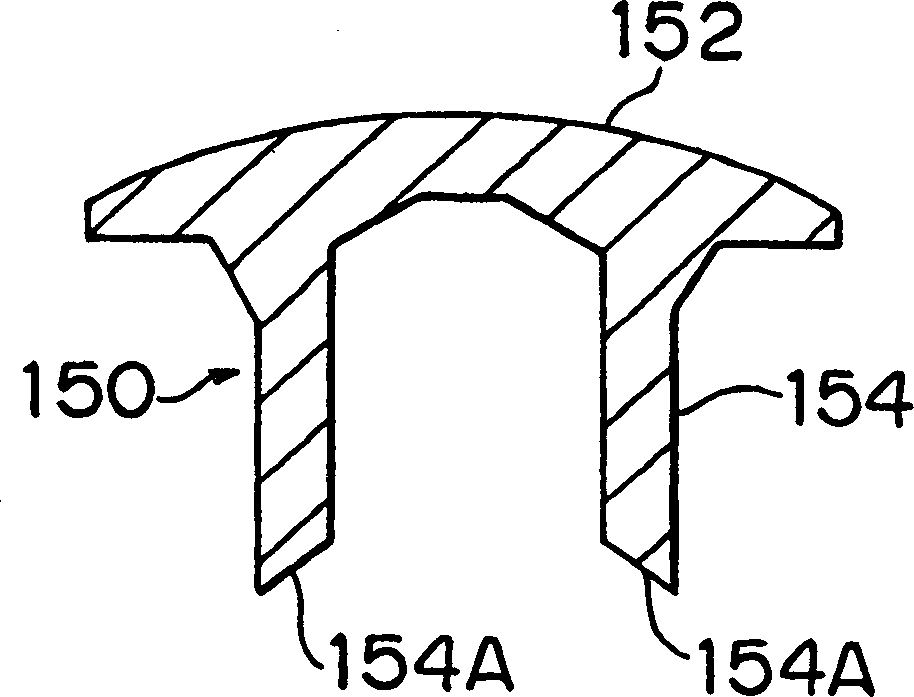

[0054] Such as Figure 7 As shown, the rivet 10 of this embodiment is a hollow rivet, which consists of a head 12 and a cylindrical portion 14 extending from the back of the head 12 . The head 12 of the rivet 10 has an inverted frusto-conical recess 20 in its substantially central portion. In addition, on the bottom 22A of the cylindrical portion 14 of the rivet 10 there is a conical protrusion 24 .

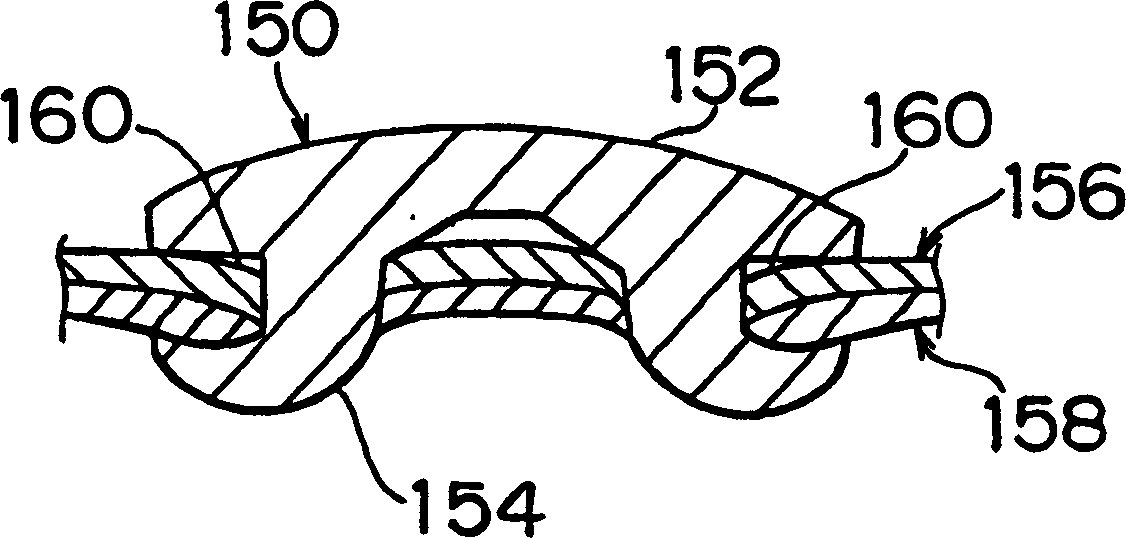

[0055] Next, a method of riveting or fastening using the rivet of this embodiment will be described. At first, as Figure 6A As shown, the distal end 14A of the cylindrical portion 14 of the rivet 10 is placed on one of the two plates 16 and 18 to be fastened (16).

[0056] Next, if Figure 6B As shown, a first punch 32 is used to press or hit the head 12 of the rivet 10, so that the die 34 arranged on this side of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com