Bolt

A bolt and screw technology, applied in the field of fastening parts, can solve the problems of inconvenient operation, inconvenience of secondary use, inconvenient installation and disassembly of bolts, etc., and achieve the effect of expanding the scope of application, improving the fastening strength and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

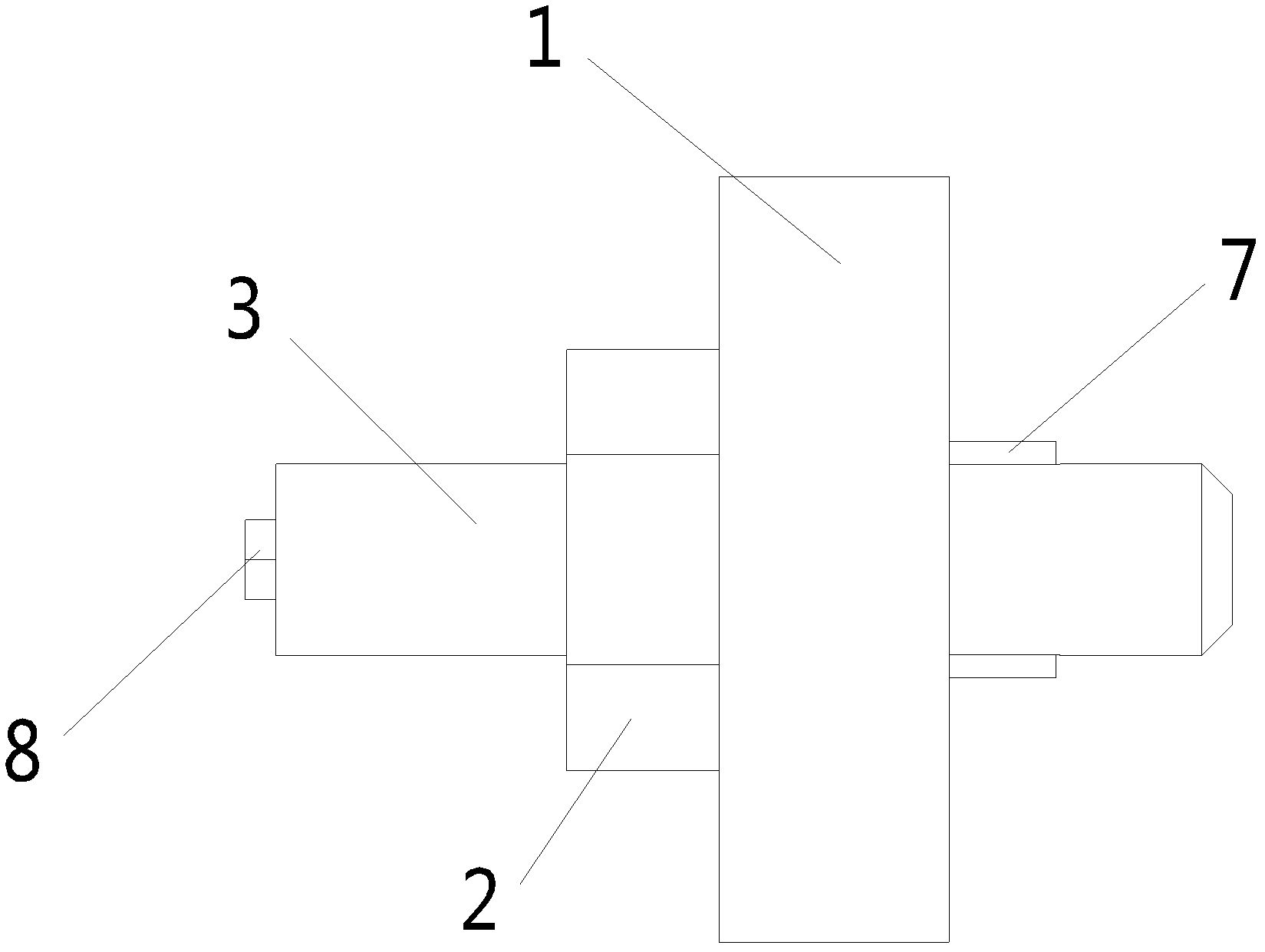

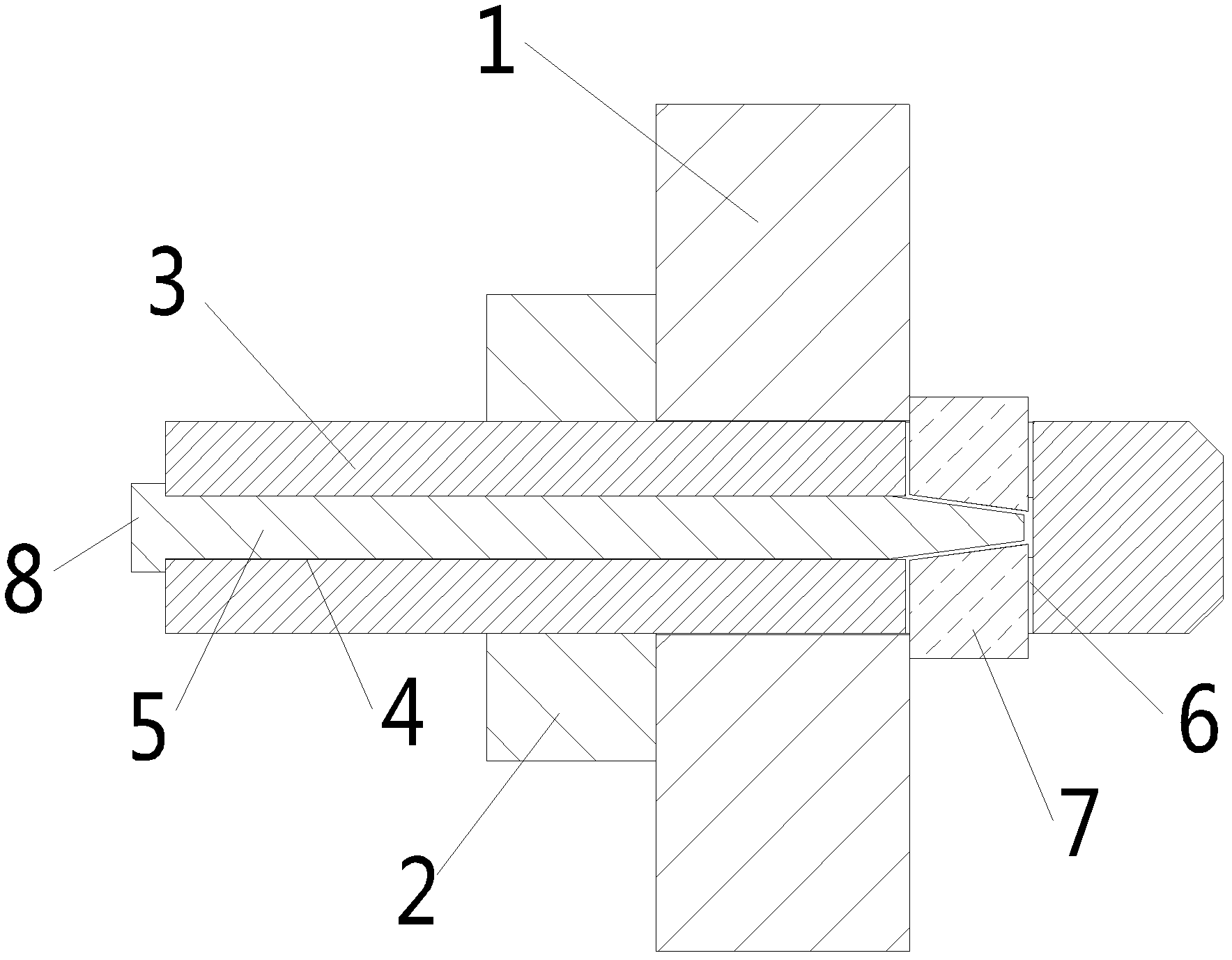

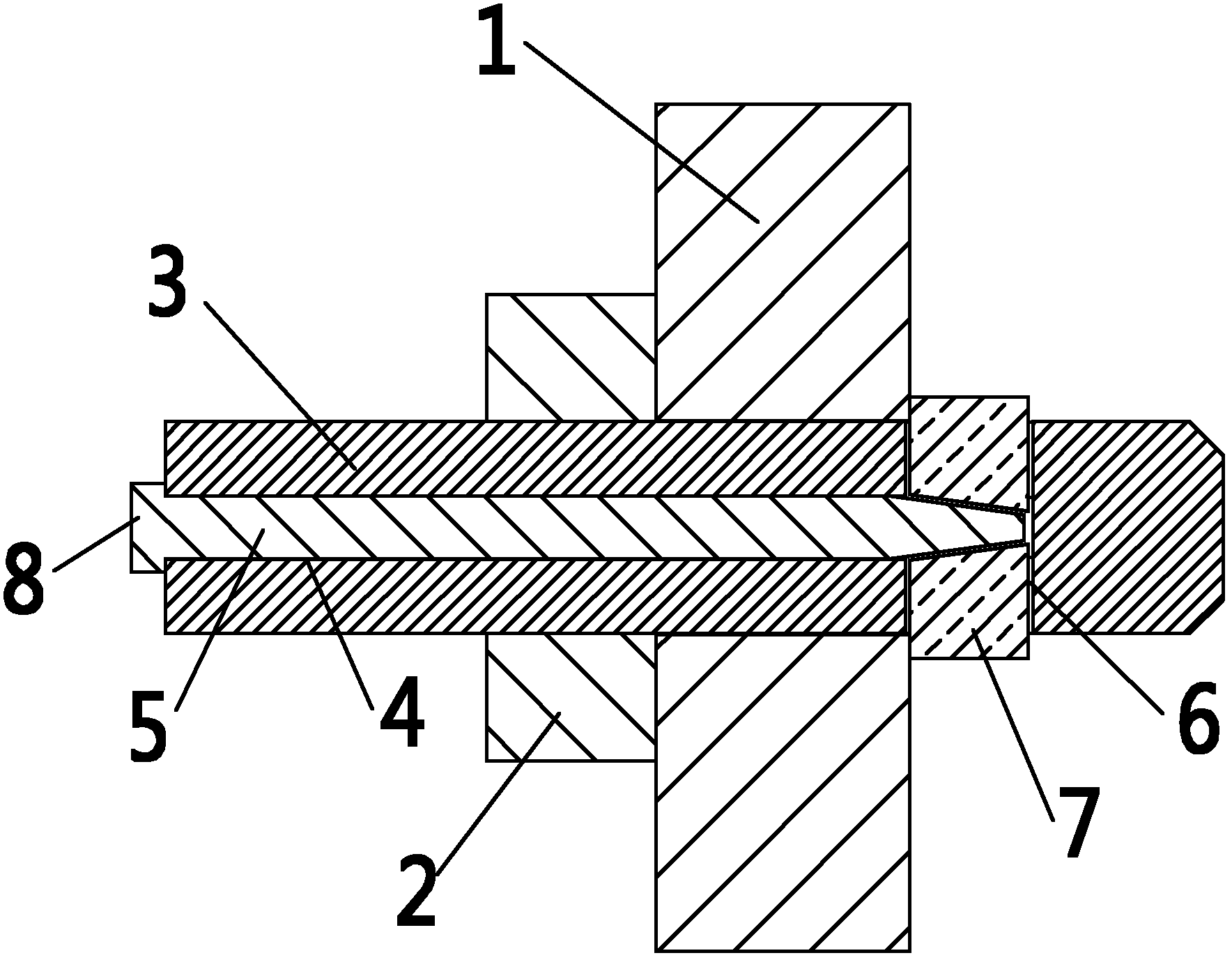

[0014] The present invention is described below in conjunction with accompanying drawing.

[0015] attached figure 1 , 2 It is a bolt according to the present invention, comprising a screw 3, a nut 2, a push rod 5 and a block 7; the center of the screw 3 has a guide hole 4 coaxial with the screw 3; the push rod 5 is threaded Connection, located in the guide hole 4, and the top of the push rod 5 inserted into the guide hole 4 is tapered; on the circumference of the screw rod 3, there is a through groove 6 in the direction perpendicular to the centerline of the guide hole 4; There are two through grooves 6, which are symmetrical with respect to the axis of the screw rod 3; there are two stoppers 7, and they are all located in the through groove 6; the stoppers 7 can slide in the through groove 6; The bottom surface of the block 7 is a slope, and the slope of the bottom surface of the block 7 is the same as the tapered surface of the push rod 5;

[0016] During use, first rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com