Road paving machine

A paving machine and road technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of inability to use support devices, insufficient functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

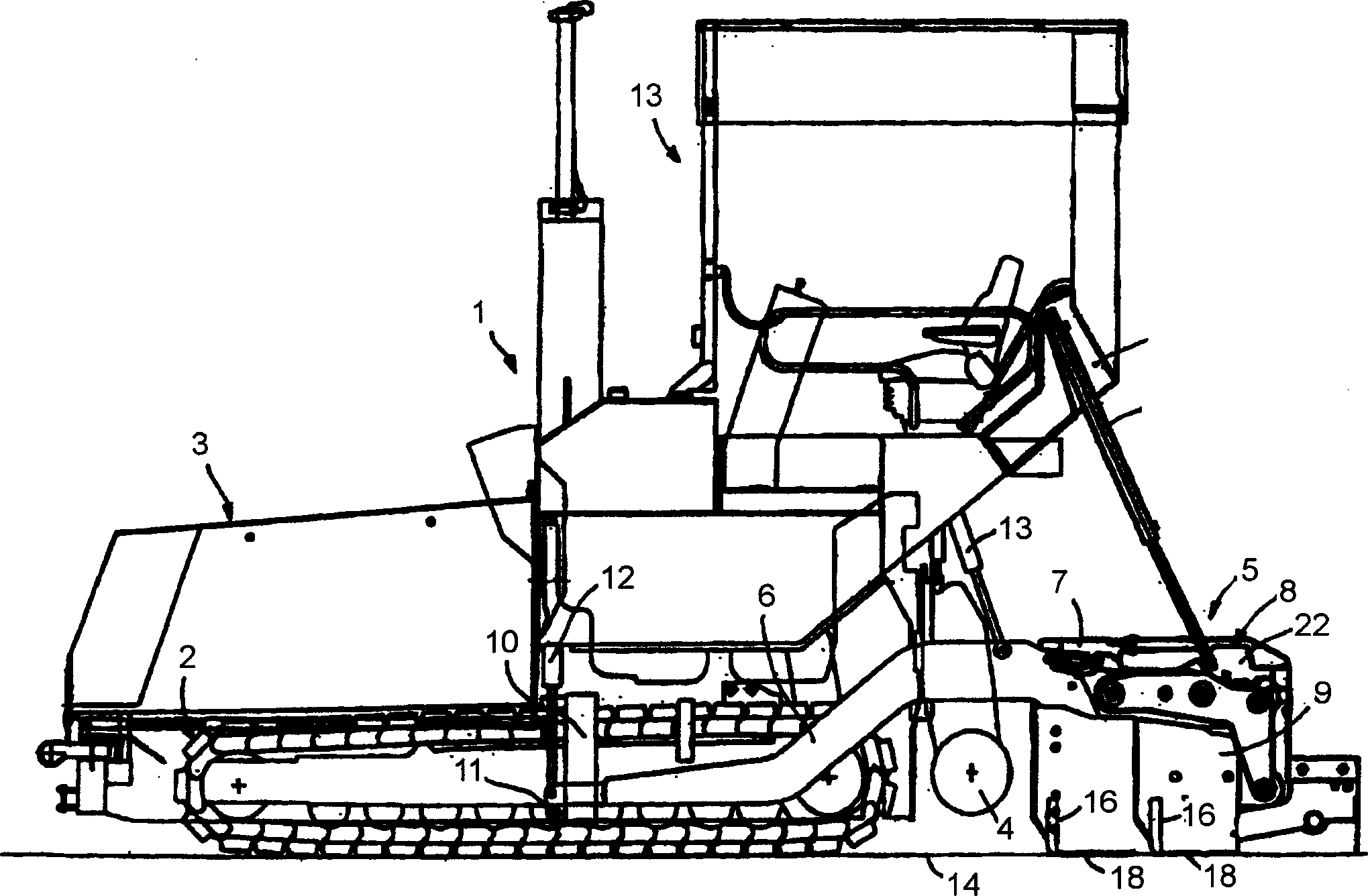

[0027] The paving machine shown in the non-working state for paving roads etc. comprises a chassis 1 with a crawler-type traveling mechanism 2 (which can be replaced by a wheel-type traveling mechanism), the chassis 1 has a hopper 3 at the front and At the rear there is a distributor screw 4, between which a conveyor (not visible) is arranged for transferring the mixture to be laid out from the hopper 3 via a delivery chute into the area of the distributor screw 4 , the superstructure is located above the chute.

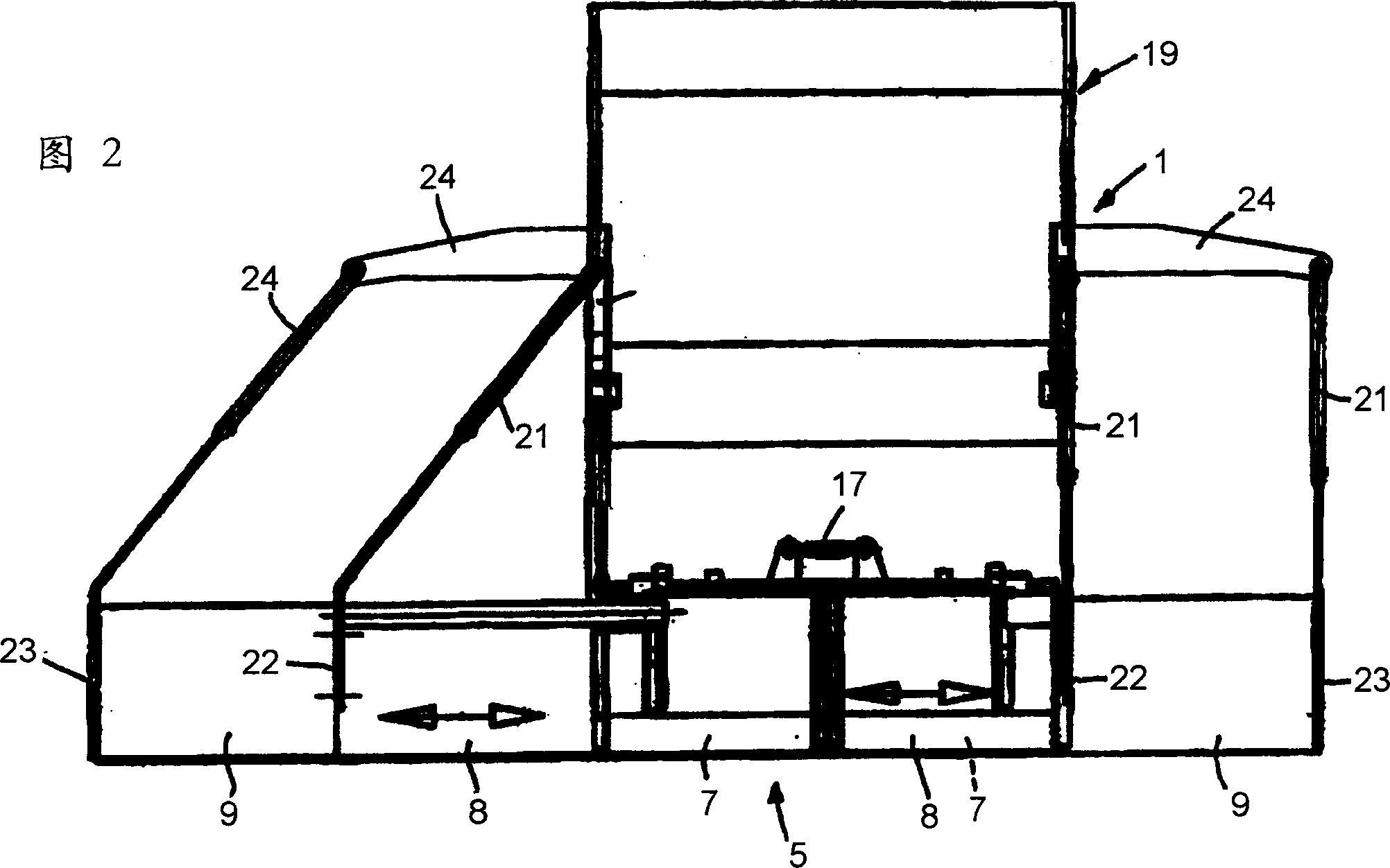

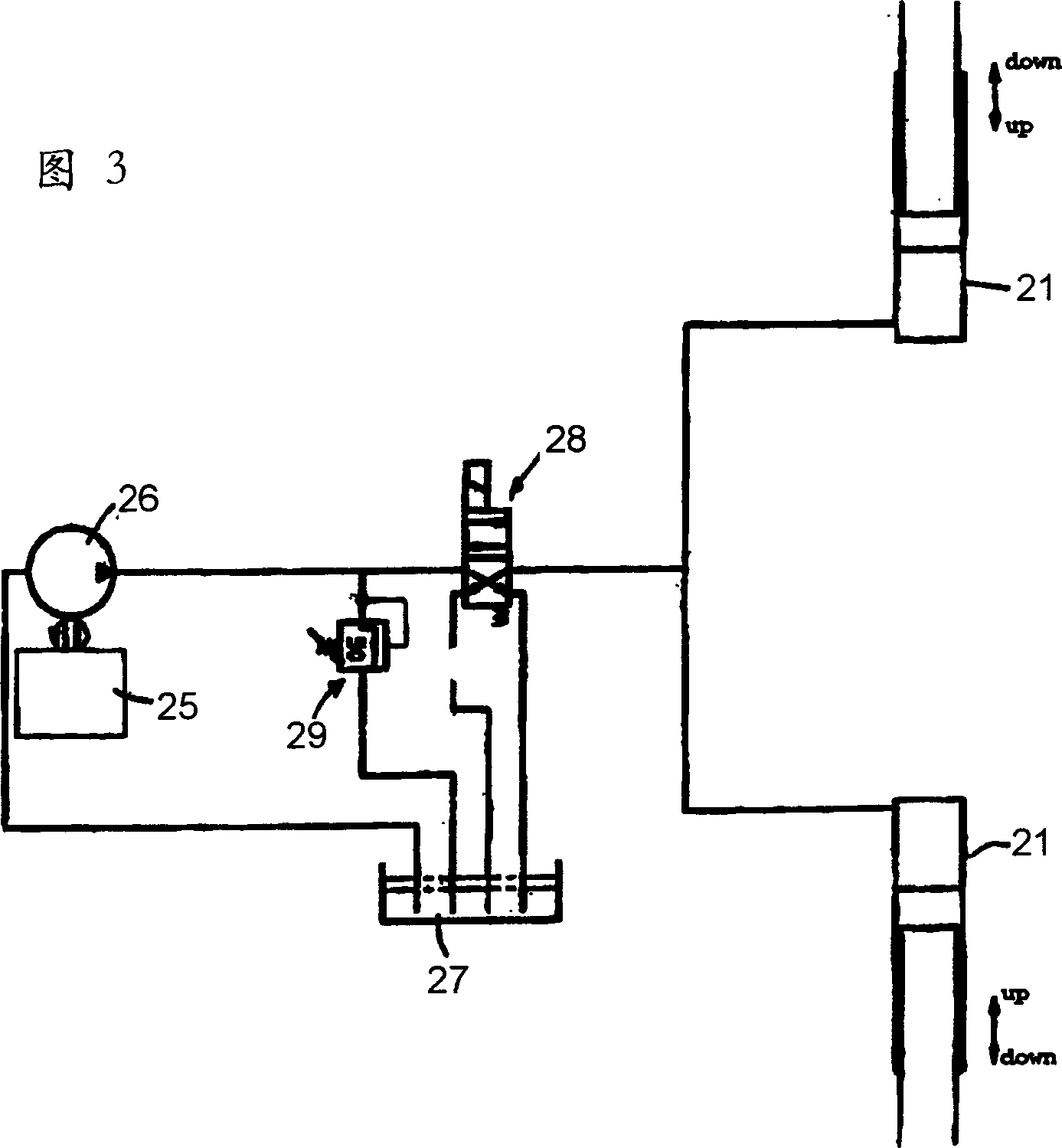

[0028] A floating screed 5 for floating laying of the mixture to be laid is articulated to the chassis 1 via trailing arms 6 . In laying direction, the screed 5 is located after the area of the distributor screw conveyor 4 and may comprise a basic screed 7 and may also comprise extendable screeds which are transversely extendable with respect to said basic screed 7 and which are independent of each other 8. The basic screed 7 is divided centrally in a conventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com