Pre-tightening force adjusting structure, chassis suspension assembly and robot

A pre-tightening force adjustment and chassis technology, applied in the field of robots, can solve the problems of inconvenient spring replacement, small elastic coefficient, poor stability, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

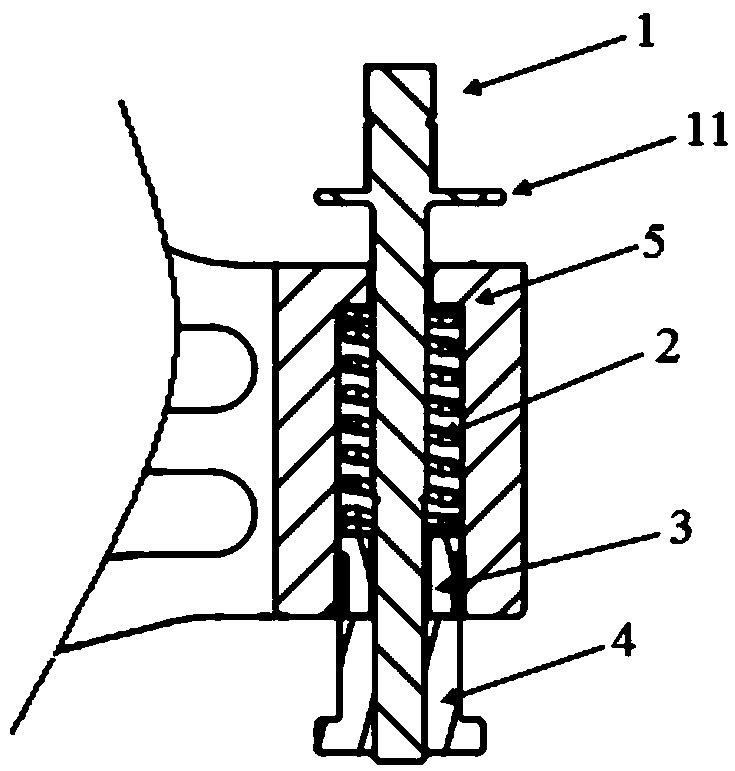

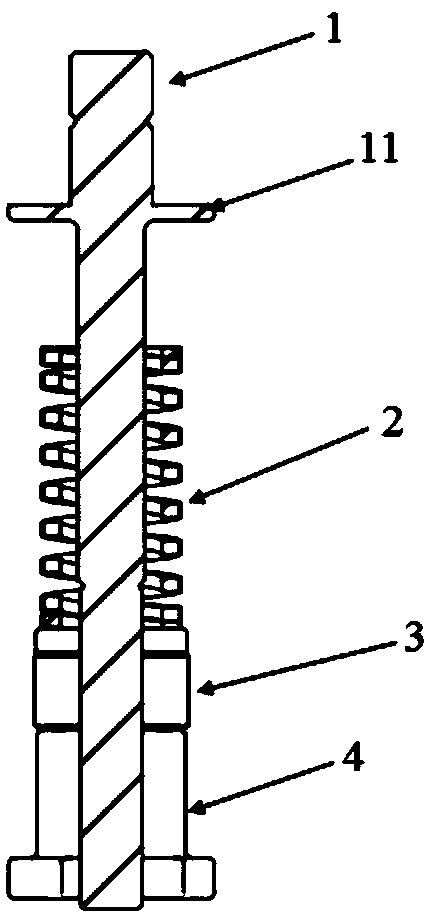

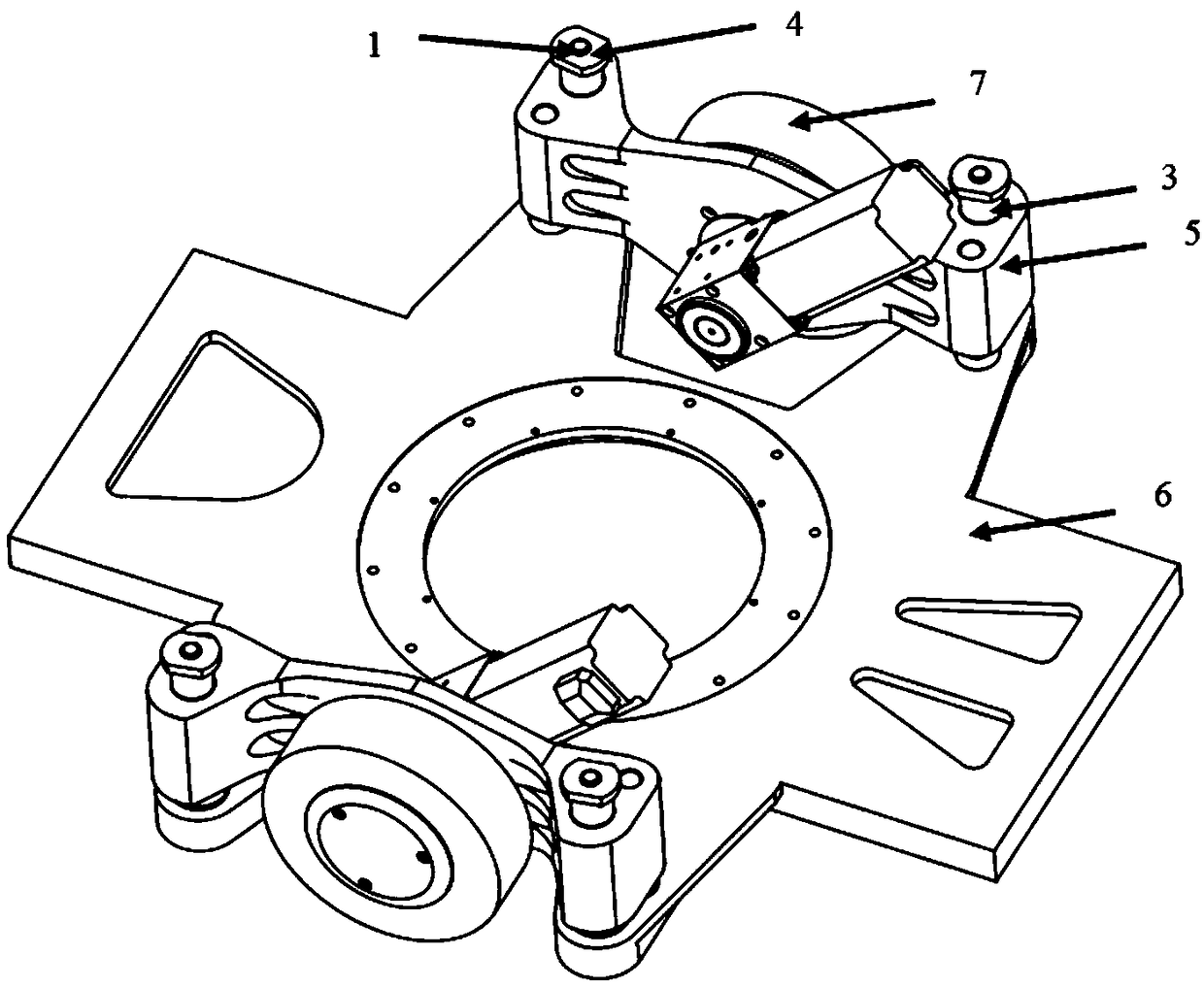

[0034] like Figure 1-4 As shown, the preload adjusting structure of this embodiment includes two guide posts 1 , two elastic members 2 , two guide sleeves 3 , two fixing members 4 and a connecting rod 5 . Wherein, the guide post 1 of the present embodiment is a cylindrical structure with a certain length, and the lower end of the guide post 1 has threads for threaded connection with the fixing part 4, and the fixing part 4 of the present embodiment is a fastening nut; The upper end is used to be fixed on a structural member, and the structural member in this embodiment can be a chassis, a support beam, and other structures that need to be adjusted for stability. In addition, there is an annular protrusion on the guide post 1 near the upper end of the guide post 1, and the annular protrusion is used for quick positioning of the above-mentioned structural components.

[0035] The guide sleeve 3 of this embodiment is a self-lubricating guide sleeve with a through hole in the mi...

Embodiment 2

[0041] The difference between the pretightening force adjustment structure of this embodiment and the first embodiment lies in that the structure of the connecting rod is different, and the number of guide posts, elastic parts, guide sleeves and fixing parts is different.

[0042] Specifically, the preload adjusting structure of this embodiment includes a guide post, an elastic member, a guide sleeve, a fixing member and a connecting rod. Wherein, the guide post is a cylindrical structure with a certain length, and the lower end of the guide post has a thread for threaded connection with the fixing part, and the fixing part is a fastening nut; the upper end of the guide post is used for fixing on the structural part, and the structural part can be Chassis, support beams and other structures that need to be adjusted for stability. In addition, there is an annular protrusion on the guide post and near the upper end of the guide post, and the annular protrusion is used for quick ...

Embodiment 3

[0049] The difference between the pretightening force adjustment structure of this embodiment and the first embodiment is that no annular protrusion is provided on the guide post, and the upper end of the guide post is directly welded and fixed to the chassis. The structural parts of the pretightening force adjustment structure are simplified, and the processing and forming of the guide post is facilitated.

[0050] Correspondingly, the preload adjusting structure in the chassis suspension assembly is replaced with the preload adjusting structure of this embodiment, and the robot includes the chassis suspension assembly of this embodiment.

[0051] Other structures can refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com