Thermocouple of gasifier and method of making thermocouple protection sleeve

A technology of protective casing and manufacturing method, which is applied in the direction of thermometers, measuring heat, and electric devices that are directly sensitive to heat/magnetic elements, and can solve the problem of not being able to get a good solution. Thermocouple protective casing Corrosion, high production costs and other problems, achieve good plugging function, strong mechanical strength, and reduce the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

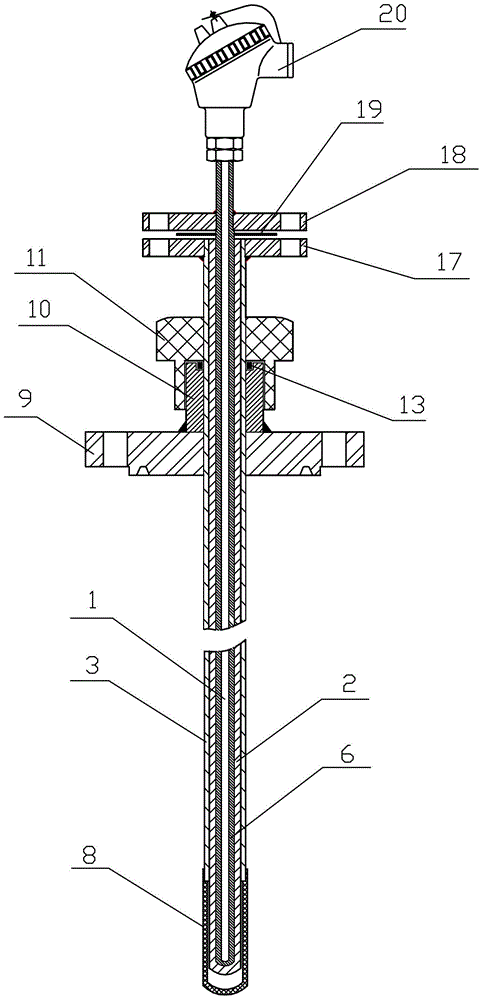

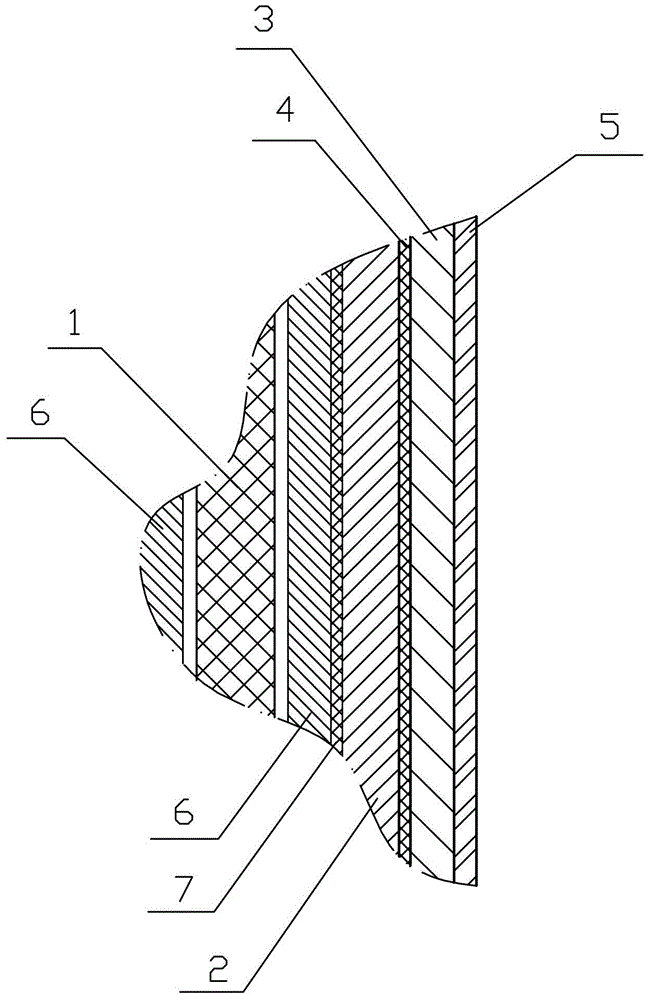

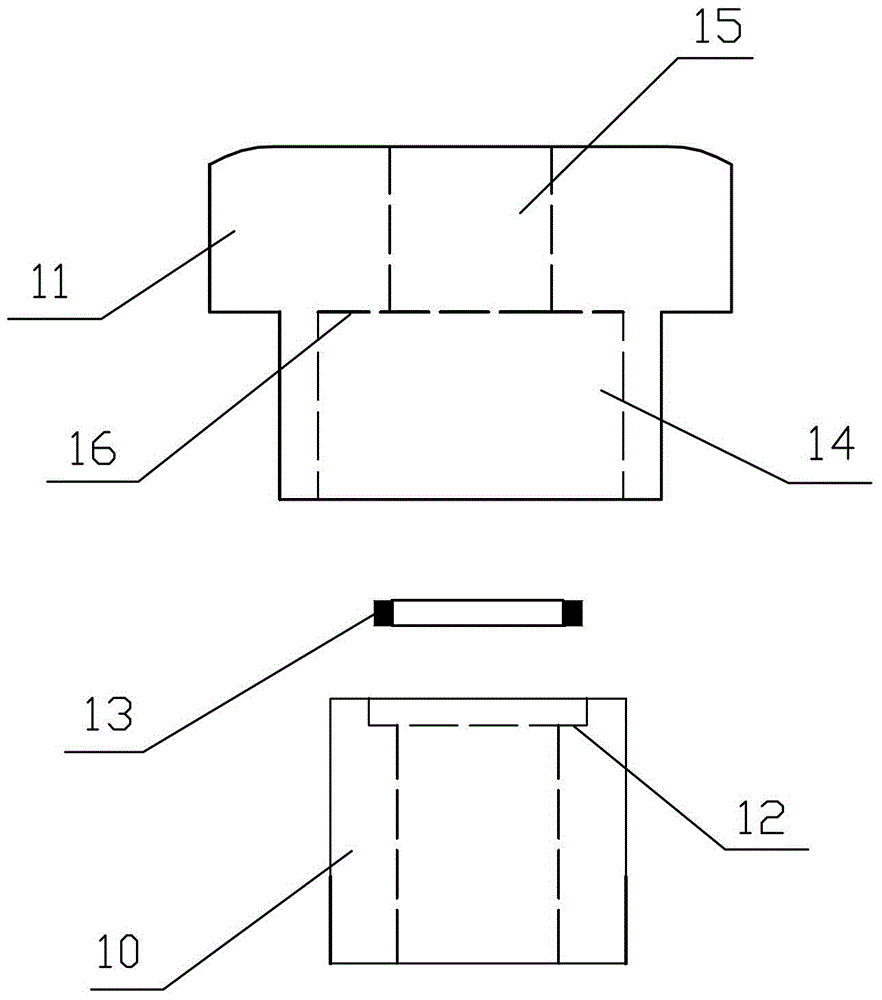

[0028] Embodiment: the gasifier thermocouple of this embodiment, such as figure 1 As shown, it includes a thermocouple 1 connected to the junction box 20 and a thermocouple protection sleeve sheathed outside the thermocouple 1 . The thermocouple protection sleeve includes a non-metallic protection tube 2 with one end closed, a metal inner protection tube 6 with one end closed, and a metal outer protection tube 3 surrounding the outer surface of the non-metallic protection tube. Such as figure 2 As shown, the non-metallic protective tube 2 is formed by pressureless sintering of submicron silicon carbide powder, the metal inner protective tube 6 is inserted into the inner hole of the non-metallic protective tube 2, and the metal inner protective tube 6 is made of tantalum with a weight ratio of 20%. , 60% tungsten, 13% niobium and 7% molybdenum are smelted by alloy. The outer surface of the metal inner protection tube 6 is thermally coated with a layer of molten aluminum, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com