Bottle cork for vaccum preservation

A bottle stopper and vacuum technology, applied in the field of bottle stoppers, can solve the problems that the pump cannot be integrally formed on the container and the storage is inconvenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

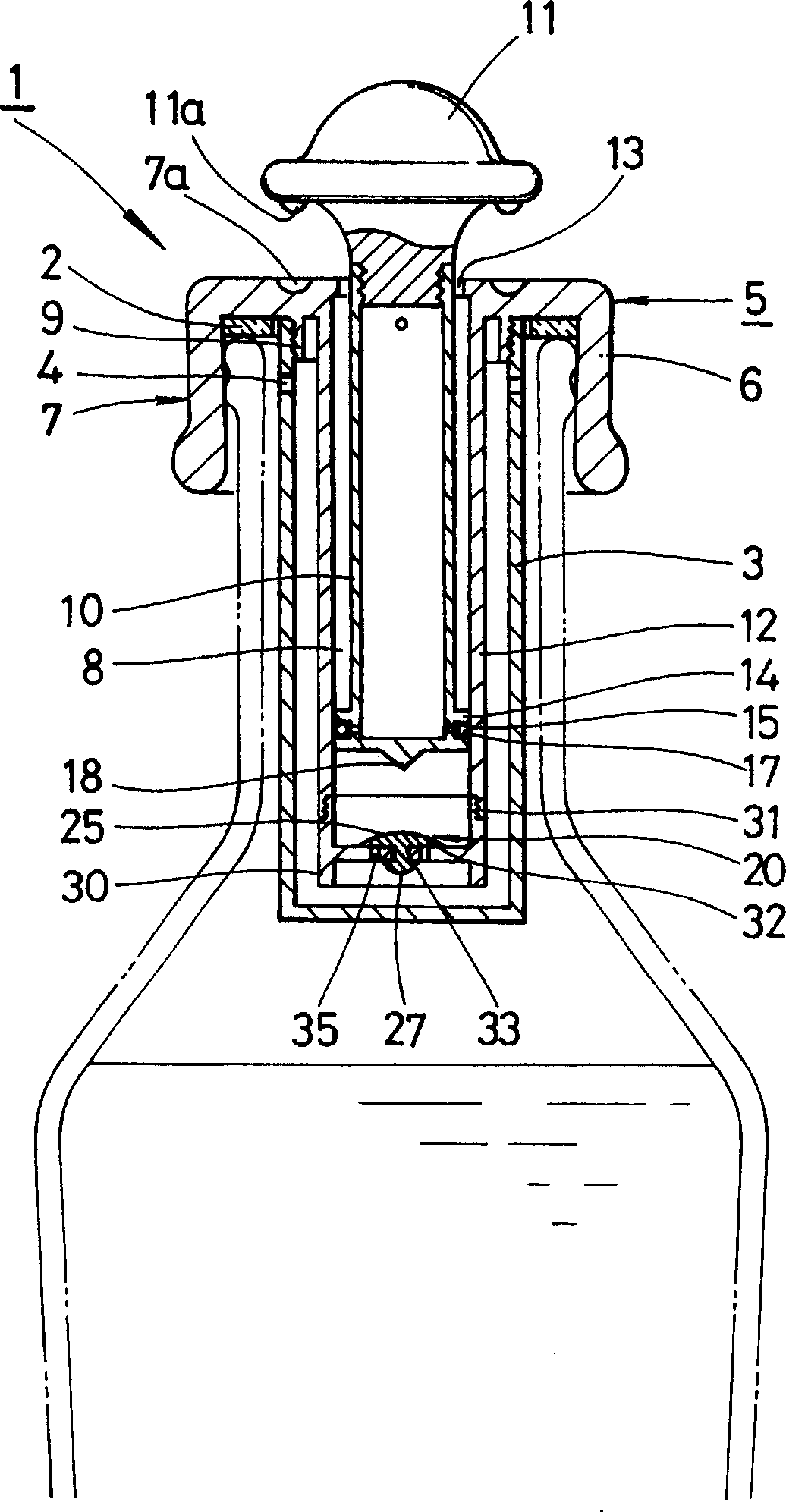

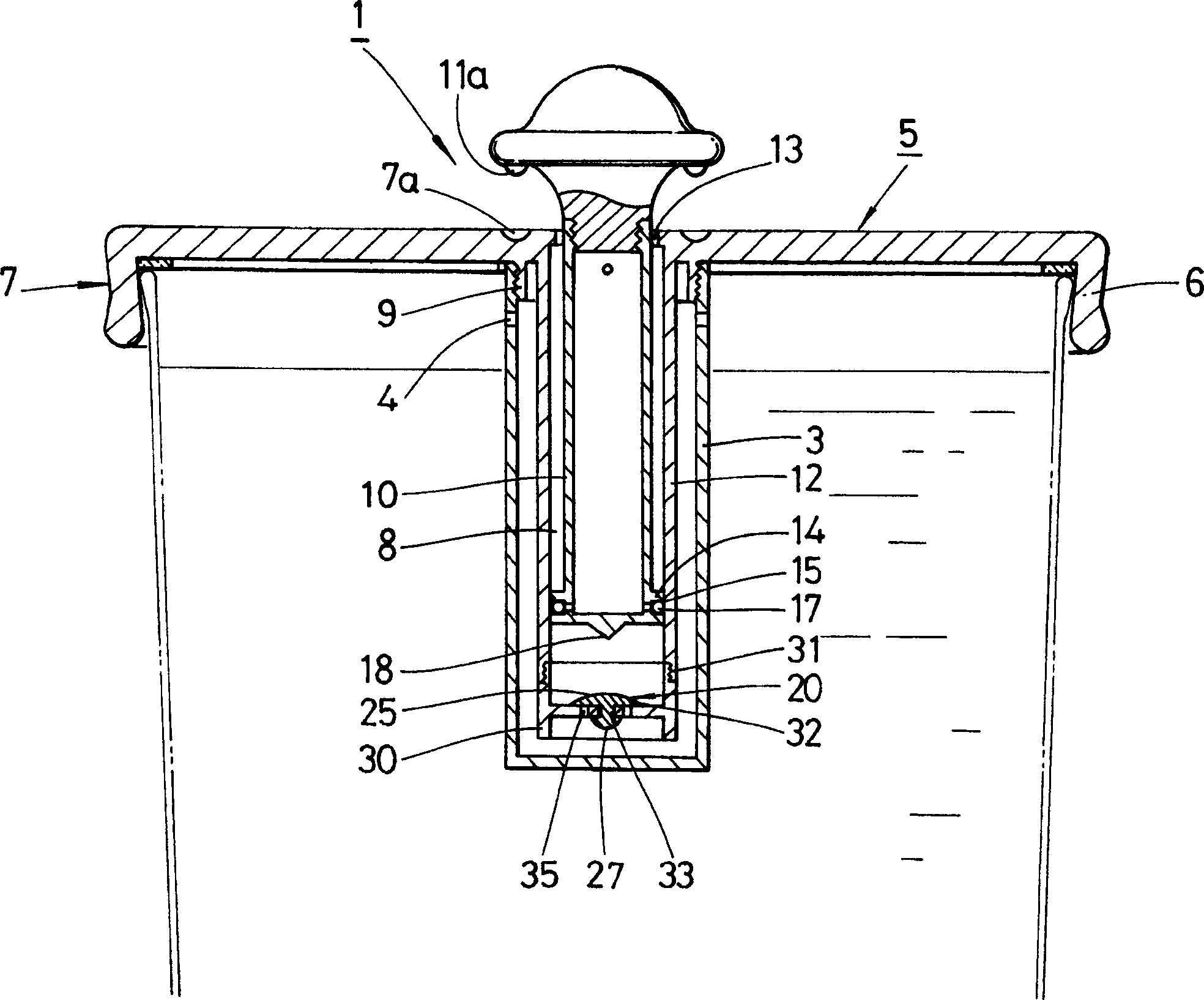

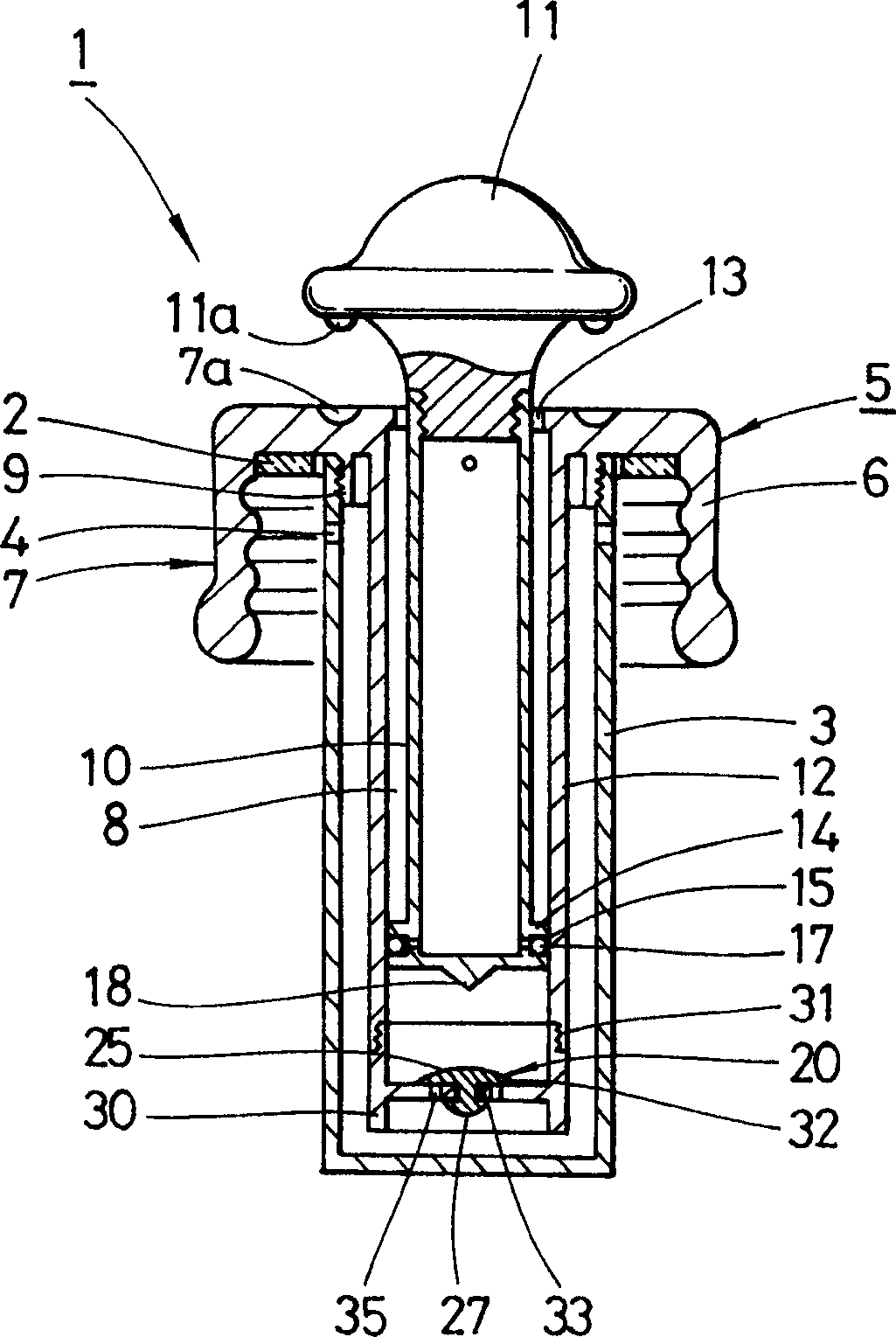

[0027] The present invention will be described in detail below with reference to the accompanying drawings.

[0028] In the bottle stopper of the present invention, the pump and the valve for forming a vacuum are integrated, and there is no need to prepare a separate pump. The following will describe how it is used as a bottle stopper.

[0029] Bottle stopper of the present invention such as figure 1 As shown, it includes: a long cylindrical plug body 5 inserted into the bottle from the mouth of the bottle, a cylindrical outer shell 3 surrounding the plug body 5, which can slide and move along the longitudinal direction of the plug body 5 in the plug body 5 The piston 10 is airtightly accommodated, and the valve member 20 is provided on the end portion of the stopper body 5 on the bottle interior side.

[0030] The stopper body 5 includes a cylindrical stopper tube 6 inserted into the bottle, and a holding portion 7 extending parallel to the stopper tube 6 and bent into a "...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap