Cabinet and construction method for its back plate

A backplane and bottomboard technology, which is applied in the construction field of cabinets and their backplanes, can solve the problems of time-consuming and labor-intensive operations for opening 4 holes on the backplane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

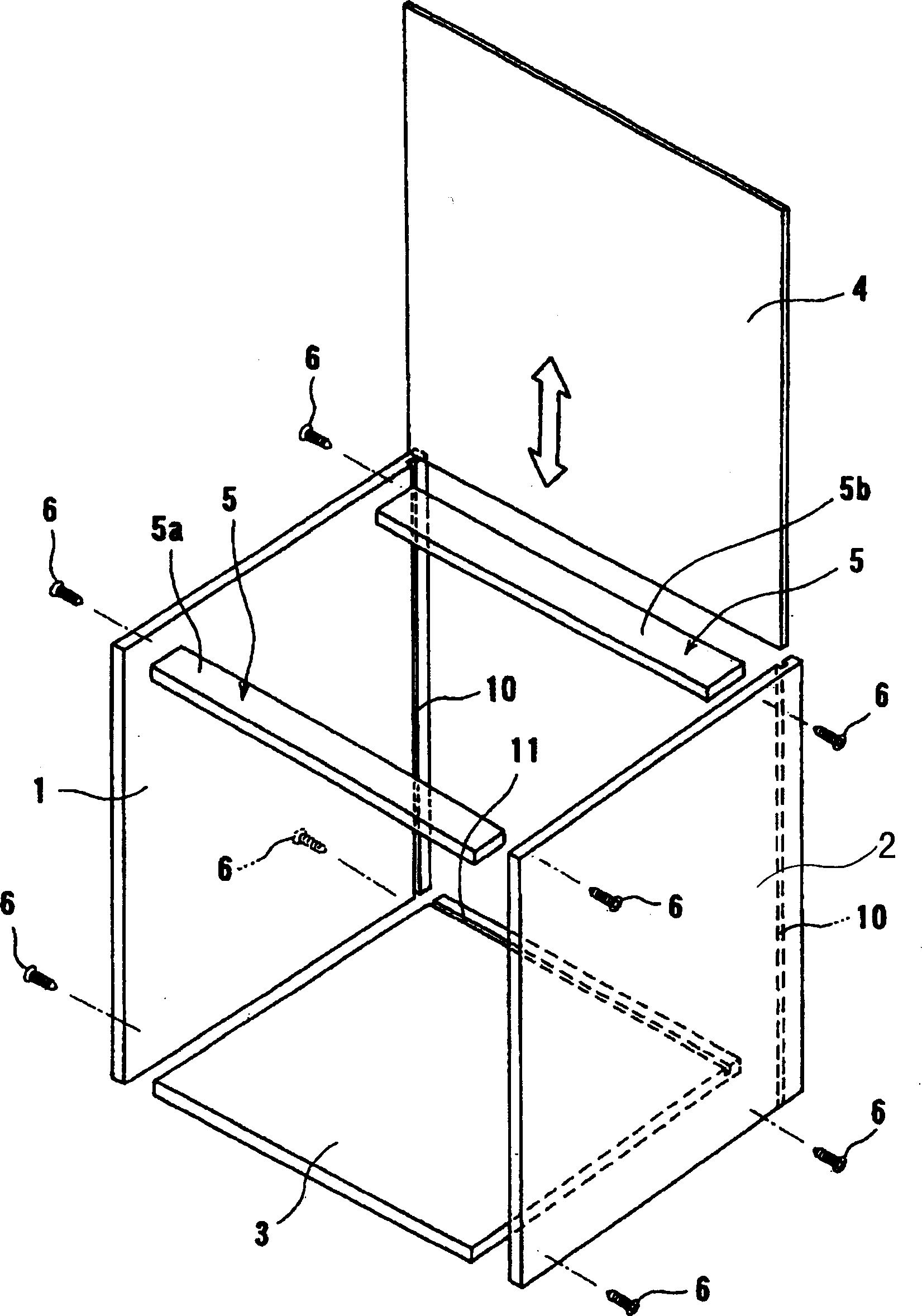

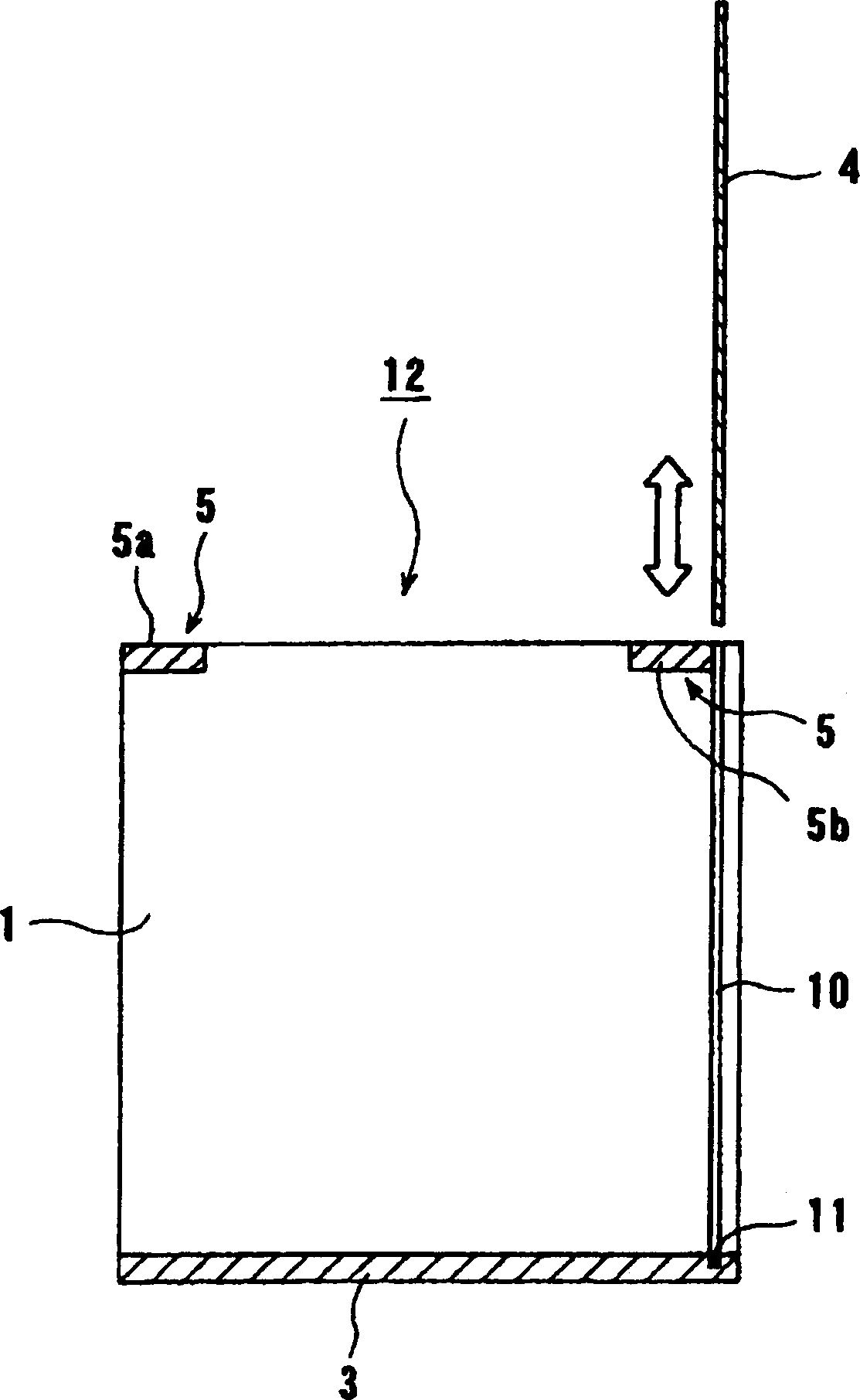

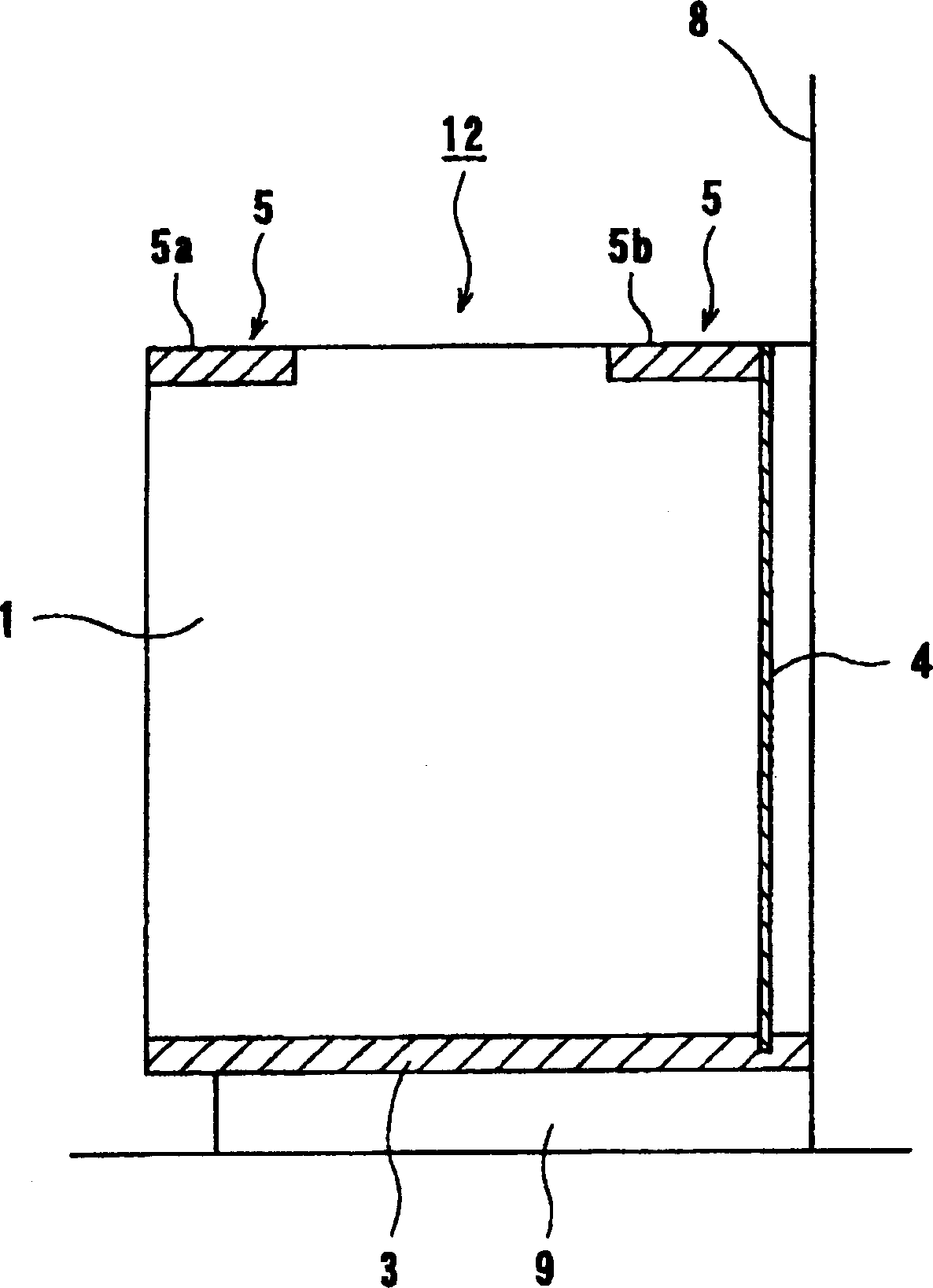

[0041] Below in conjunction with accompanying drawing, further illustrate cabinet of the present invention and backboard construction method thereof.

[0042] figure 1 , figure 2 They are respectively an exploded perspective view and a sectional view of an embodiment of the cabinet of the present invention. Such as figure 1 and figure 2 As shown, the cabinet of the present invention will be provided with the left side plate 1 and the right side plate 2 of the vertical groove 10 along the full length of the longitudinal direction at the rear end, and the bottom plate provided with the transverse groove 11 along the full length of the transverse direction at its rear end is separated 3, and make the faces forming the vertical grooves 10 face each other, and at the same time make the vertical grooves 10 and the horizontal grooves 11 communicate. An upper part 5 is arranged between the upper ends of the left and right side plates 1, 2. In this embodiment, the upper part 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com