Screw compressor

A technology of screw compressors and compressors, applied in compressors, irreversible cycle compressors, refrigerators, etc., can solve problems such as pressure vibration and noise, and achieve the effect of maintaining shock absorption channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

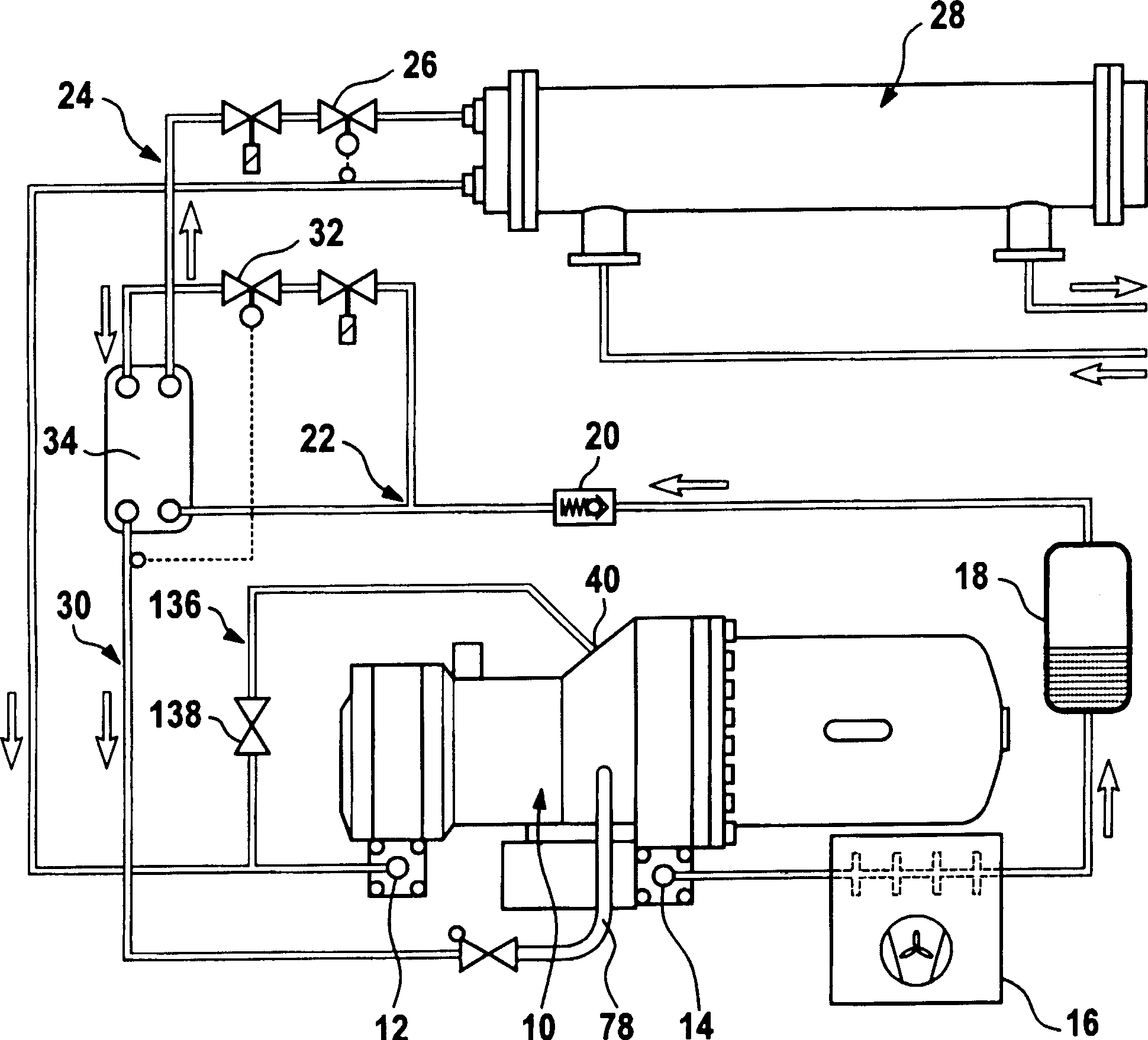

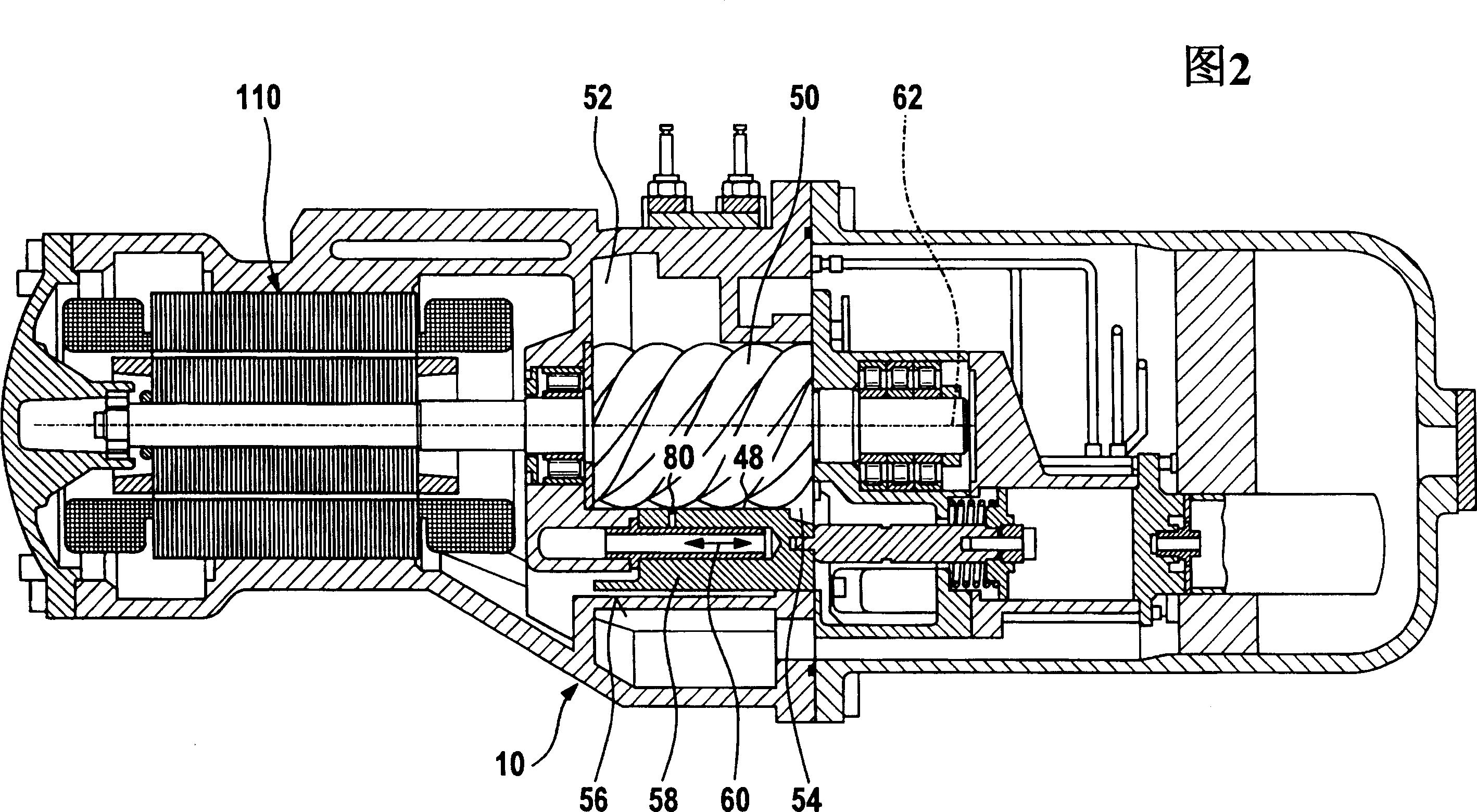

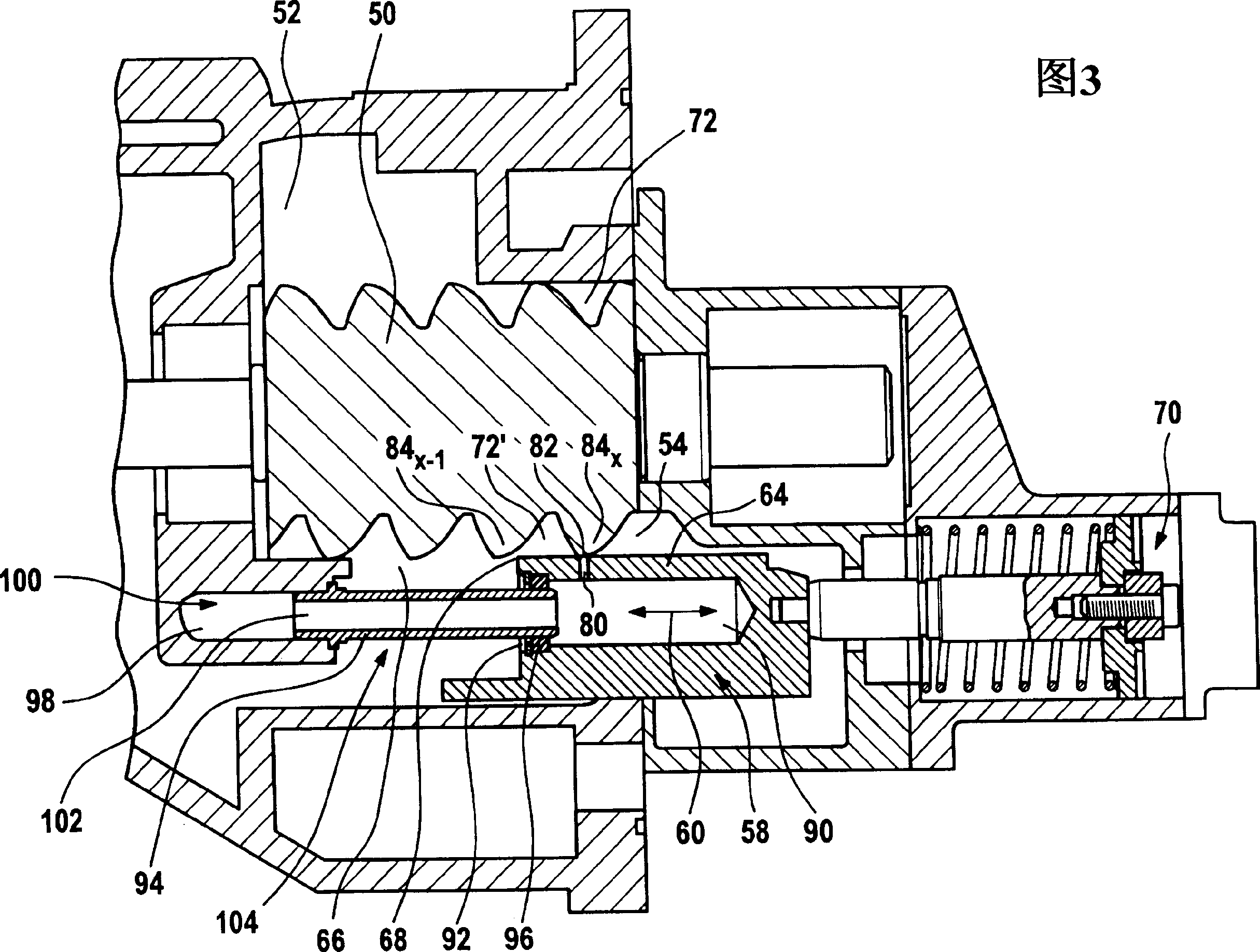

[0049] figure 1 The shown first embodiment of the screw compressor according to the invention comprises a compressor housing generally designated 10 with a suction connection 12 and a pressure connection 14, wherein a refrigerant medium is sucked in at the suction connection 12 and at the pressure connection 14 discharges the compressed refrigerant medium.

[0050] The compressed refrigerant medium discharged at the pressure connection 14 is first conveyed to a condenser 16 and from there into an intermediate store 18 for liquid refrigerant. After the intermediate storage 18, the liquid refrigerant flows through the one-way valve 20 and the branch 22, from the branch to the expansion valve 26 and the evaporator 28 through the cooling cycle line 24, and then returns to the suction from the evaporator 28. interface12.

[0051] In addition, the refrigeration circuit 24 is assigned a recooling circuit 30 which branches off from the cooling circuit 24 on the branch 22 and has an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com