Wound one-way valve

A technology of one-way valves and wounds, which is applied in the direction of control valves, valve devices, and functional valve types. It can solve the problems of air leakage, liquid leakage, difficulty in ensuring the accuracy of the spherical surface, and difficulty in ensuring the consistency of the elastic force of the return spring, etc., to achieve good elasticity. , the effect of solving the difficulty of sealing

Inactive Publication Date: 2004-11-24

朱汉衡

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The one-way valve with this structure has the following defects: when a metal ball or glass ball is used as the disc, the accuracy of the spherical surface is difficult to guarantee, resulting in air leakage and liquid leakage; It is also difficult to ensure the consistency of the spring force, especially when the pressure of the gas (liquid) flowing through the check valve is small, the difference in the spring force of the return spring is very prominent, or the spring force is too large and the airflow cannot support the valve disc. Either the elastic force is slightly smaller and the seal is not good, and the reverse gas (liquid) body takes advantage of the gap and pours in backwards

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

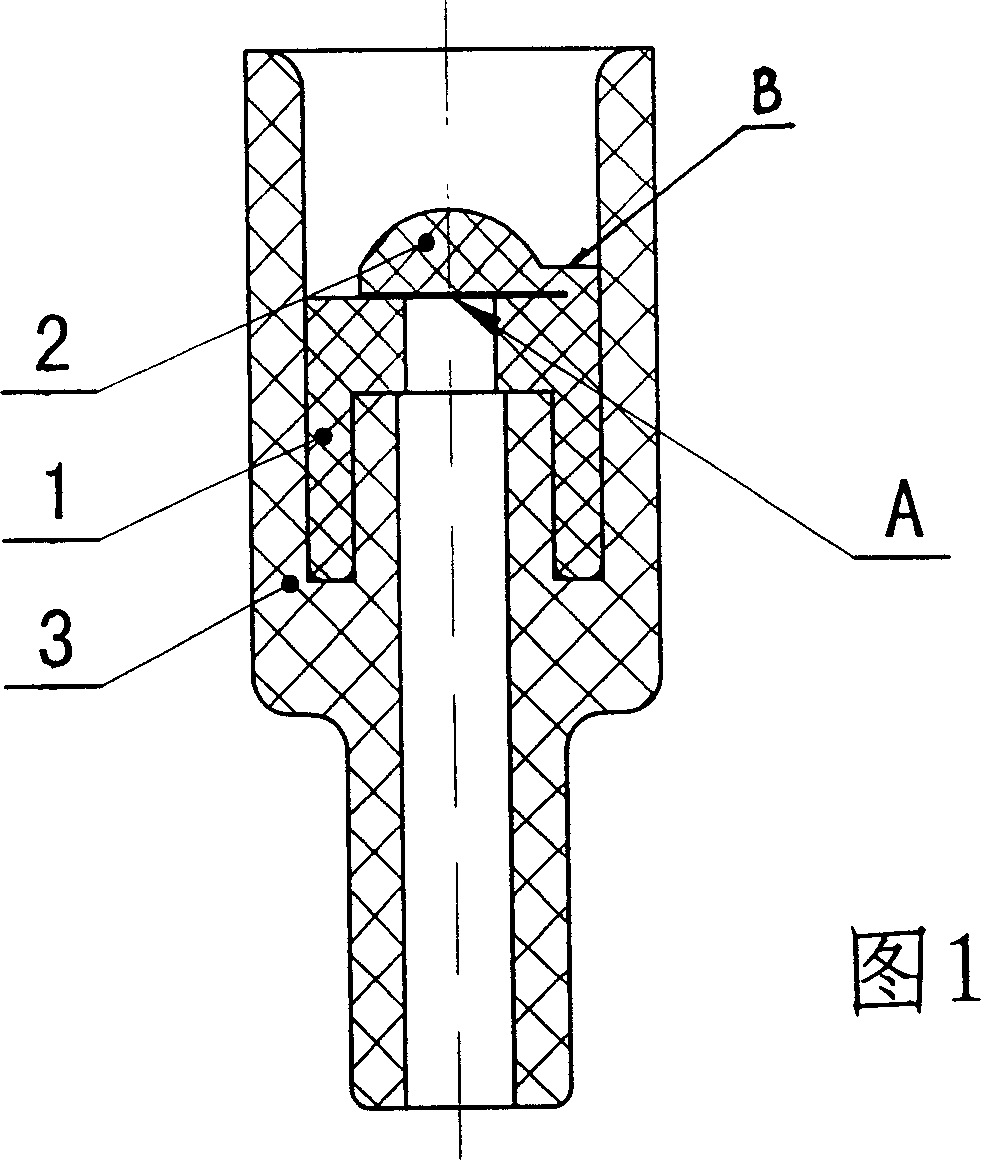

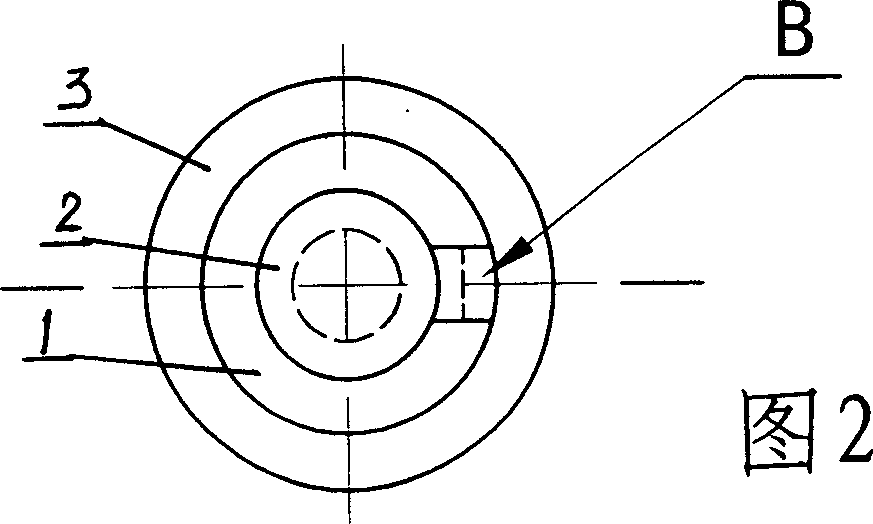

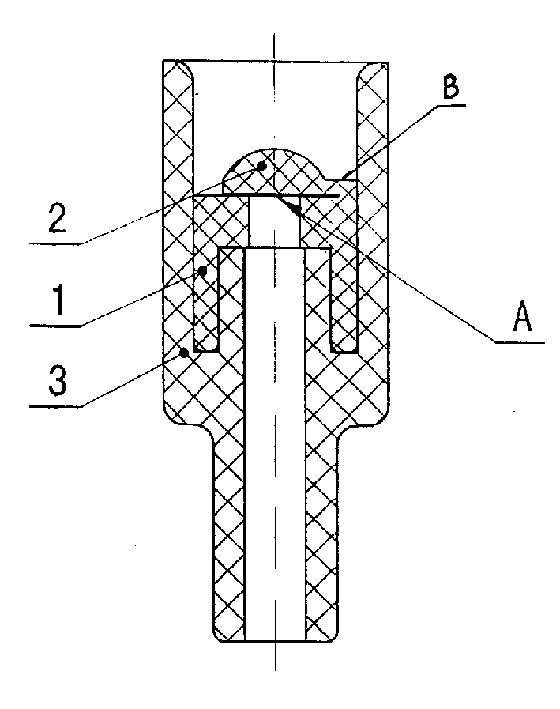

[0010] Referring to Figures 1 and 2, a wound one-way valve includes a valve body 1 and a valve disc 2, the valve disc 2 made of rubber is integrated with the valve body 1, and there is a wound A between the valve disc 2 and the valve body 1 , the valve disc 2 and the valve body 1 are arranged in the valve sleeve 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The one-way cut valve includes valve body and valve clack made of rubber and integrated with the valve body. Between the valve body and the valve clack, there is one cut. The valve body and the valve clack are set inside valve sleeve. The present invention utilizes cut as sealing surface and can seal completely. The valve body and the valve clack made of rubber have good self-restoring elasticity. During flowing in the forward direction, the fluid pressure overcomes the elasticity of the linking beam to open the valve clack for flow in the forward direction. After the fluid cuts off, the valve clack restores to close the valve body to arrest the reverse flow, resulting in no need of restoring spring. The present invention has the advantages of high sealing performance and no need of restoring spring.

Description

1. The technical field [0001] The present invention relates to a one-way valve. 2. Background technology [0002] At present, the one-way valve that can only allow fluid (gas or liquid) to flow in one direction basically adopts a spherical valve disc or a flat disc, and adds a return spring to block the sealing port in the valve body. The one-way valve of this structure has the following defects: when a metal ball or a glass ball is used as the valve disc, it is difficult to ensure the accuracy of the spherical surface, resulting in the occurrence of air leakage and liquid leakage; The consistency of the spring force is also difficult to guarantee, especially when the pressure of the gas (liquid) flowing through the one-way valve is small, the difference in the spring force of the return spring is very prominent, or the spring force is slightly large and the air flow cannot open the valve disc, Either the elasticity is slightly smaller, the sealing is not good, and the reve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16K15/14

Inventor 朱汉衡

Owner 朱汉衡

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com