Multiple disc clutch for automatic transmission

A technology for automatic transmissions and clutches, applied in the direction of fluid-driven clutches, mechanical-driven clutches, clutches, etc., can solve the problems of slow engine output, increasing the number of assembly processes of automatic transmission assembly lines, and inability to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be described in detail below according to the accompanying drawings.

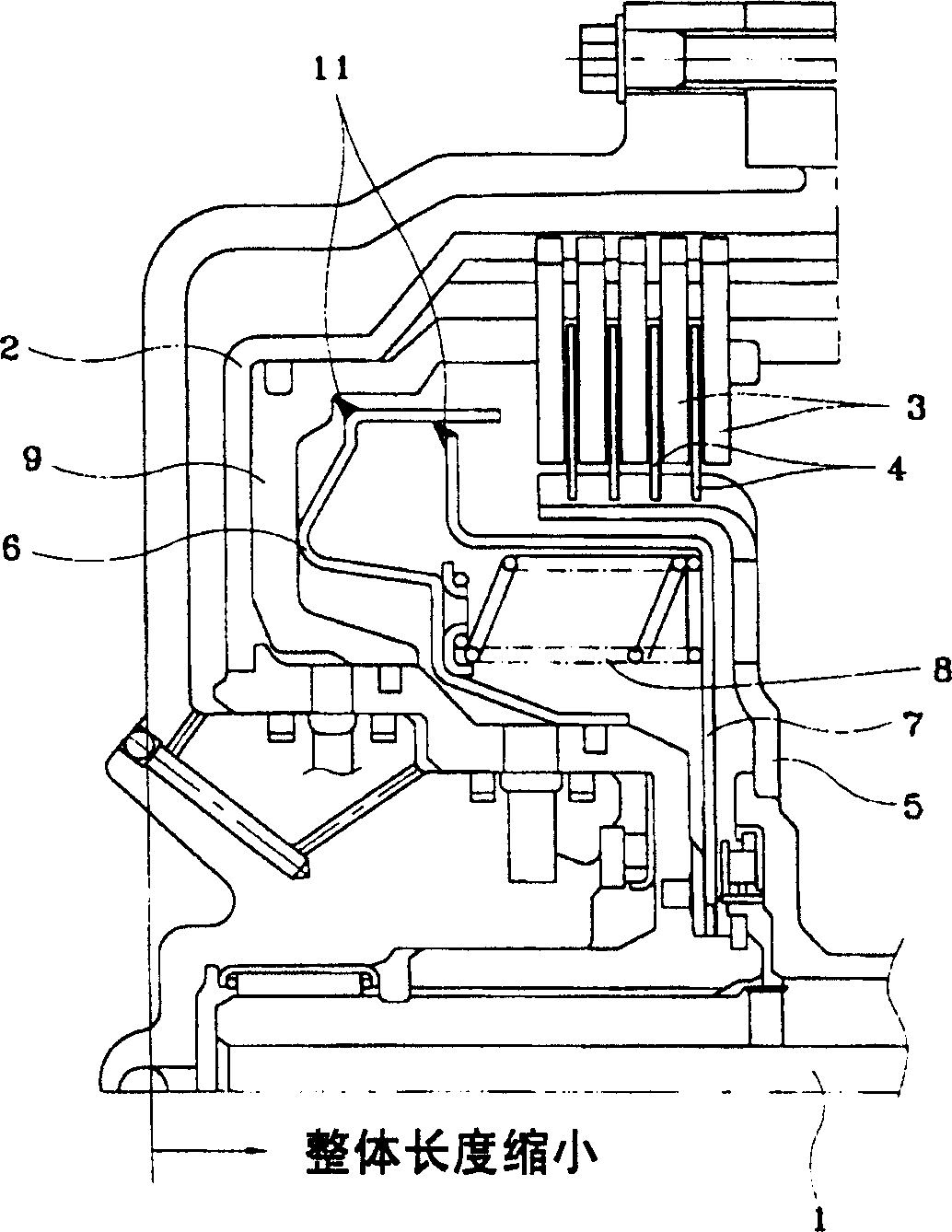

[0011] figure 1 It is a cross-sectional view of the multi-plate clutch of the automatic transmission according to the present invention, and it is characterized in that the thickness of the piston 6 and the spring retainer (spring retainer) 7 is reduced.

[0012] Mechanical mechanism of the present invention is as shown in the figure, is identical with existing situation.

[0013] That is to say, it consists of a structure in which a plurality of clutch plates 3 are laterally movable in a keyed manner on a cage 2 that rotates together with an input shaft 1 that transmits power from the engine, and clutch plates 4 are located on these clutch plates 3, in the same way, it is connected with the hub (hub) 5, between the holder 2 and the hub 5, there is a piston 6 that slides on the holder 2 and is fixed in the axial position on the holder. The spring retainer 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com