Improved crusher

A pulverizer, an improved technology, applied in the direction of grain processing, etc., can solve the problems such as the difficulty of opening and closing the fixed tooth disc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

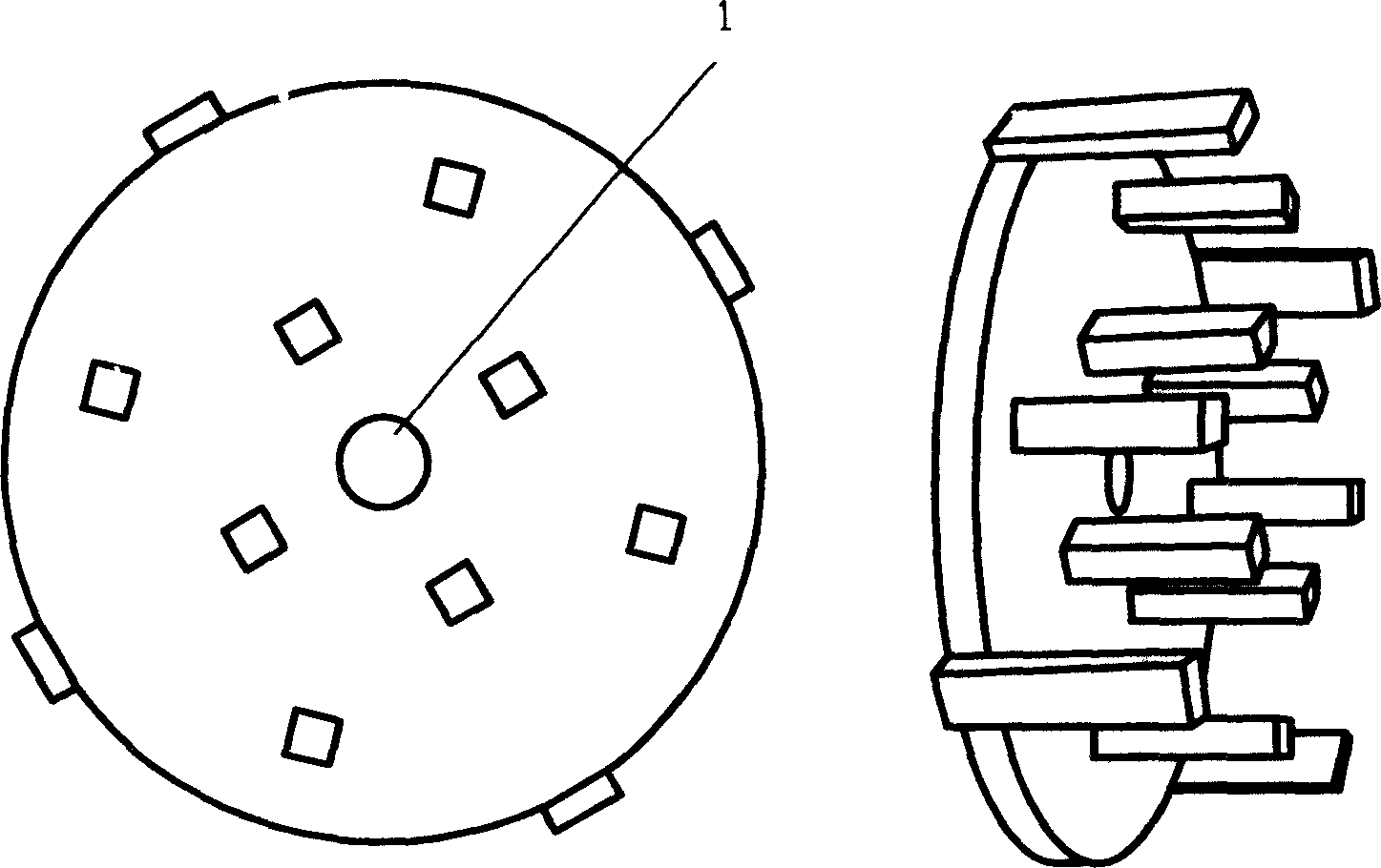

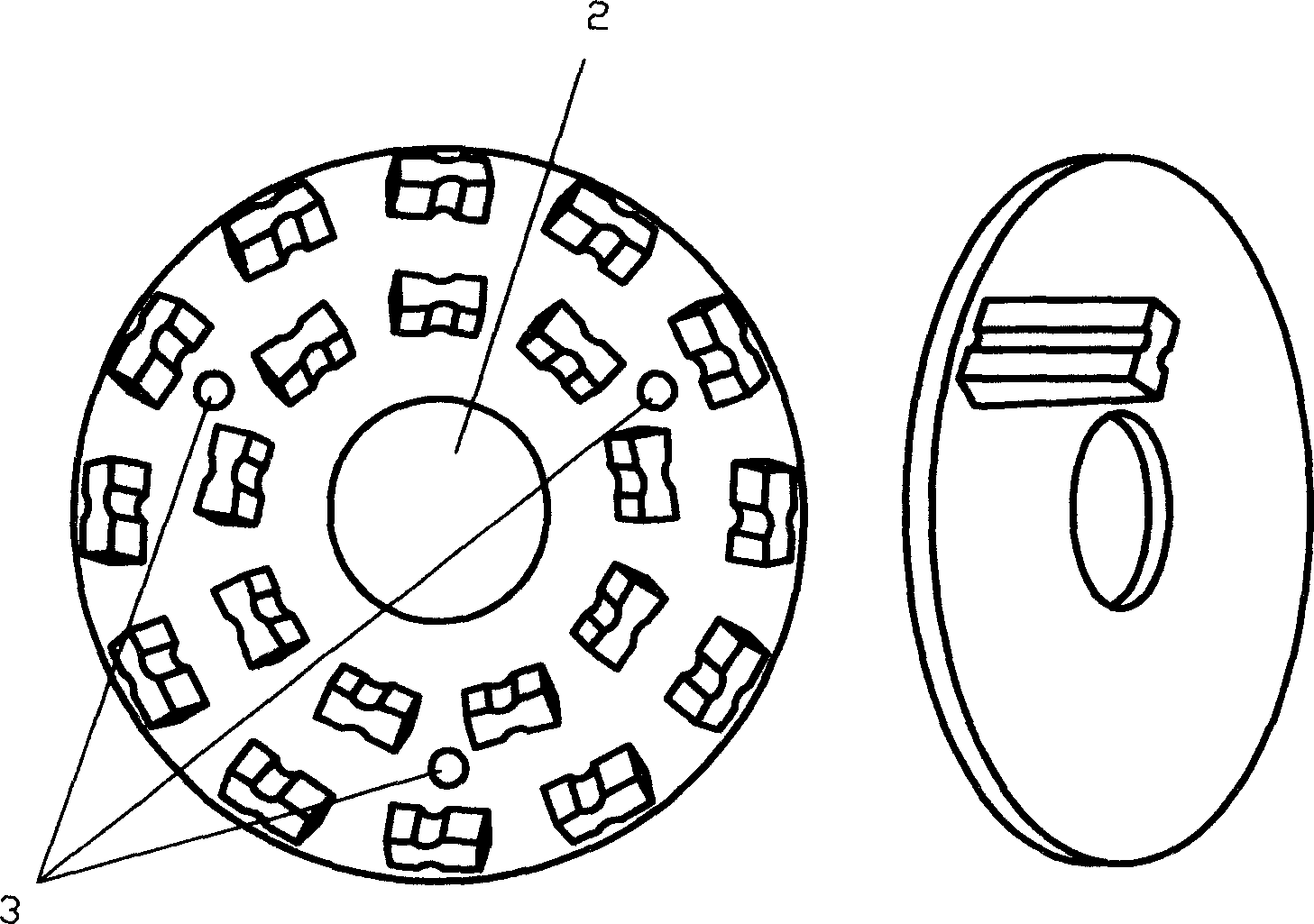

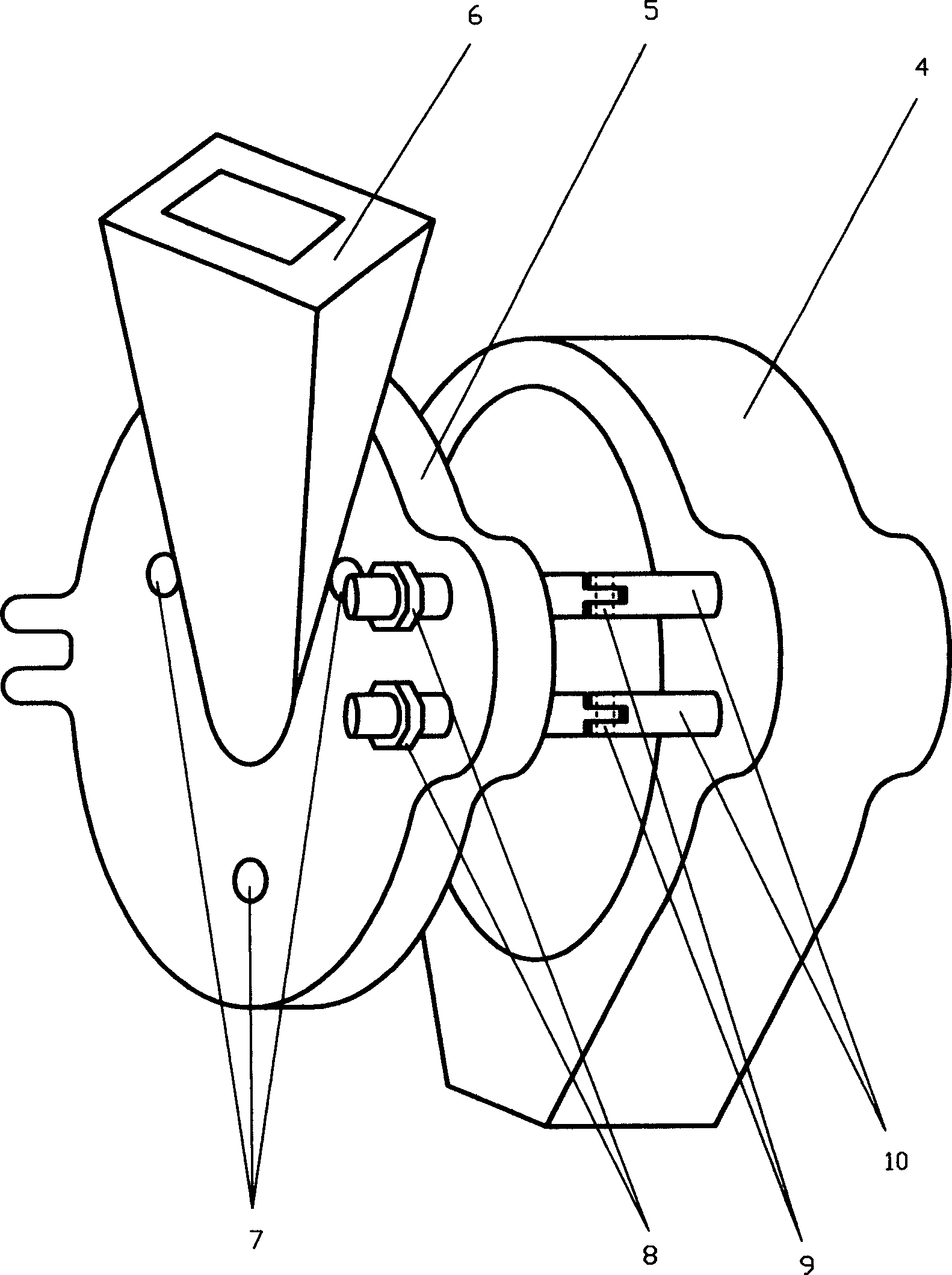

[0057] Embodiment 1: On the basis of ordinary pulverizers, the characteristic structures of inventions [1], [2], and [3] are adopted at the same time, that is, dense movable and fixed toothed discs, in-line opening and closing structures and wind power devices, to realize A pulverizer that can pulverize efficiently.

Embodiment approach 2

[0058] Embodiment 2: On the basis of the ordinary pulverizer, the characteristic structure of the invention [4] and the invention [5] are adopted at the same time, that is, the double-outlet body, the separation screen and the wind device, and a kind of permanent pulverization can be realized at the same time. , Separation of fine materials, a pulverizer that can realize the separation of slurry and slag while wet pulverization.

Embodiment approach 3

[0059] Embodiment 3: On the basis of ordinary pulverizers, the characteristic structures of inventions [1], [2], [3], and [4] are adopted at the same time, that is, dense movable and fixed toothed discs, in-line opening and closing structures, double The machine body, separation sieve and wind device realize a pulverizer that can efficiently pulverize and separate coarse and fine materials during dry pulverization, and can realize pulp and slag separation during wet pulverization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com