Aligning device for an injection nozzle

An injection nozzle and aligning device technology, applied in the field of injection molding machines, can solve the problems of not easy installation/removal of fixtures, complex and expensive fixture structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

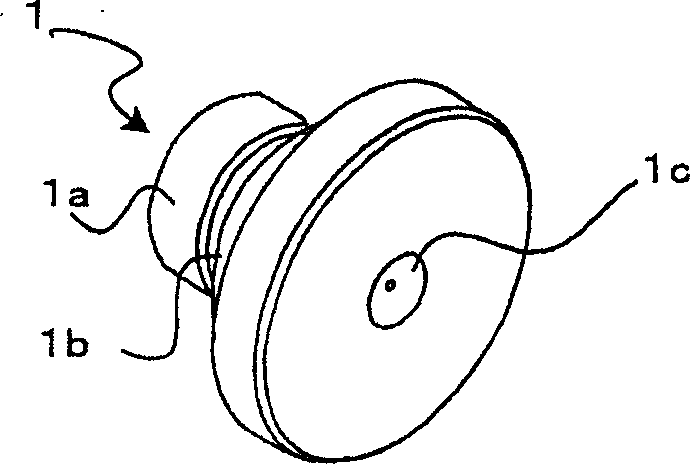

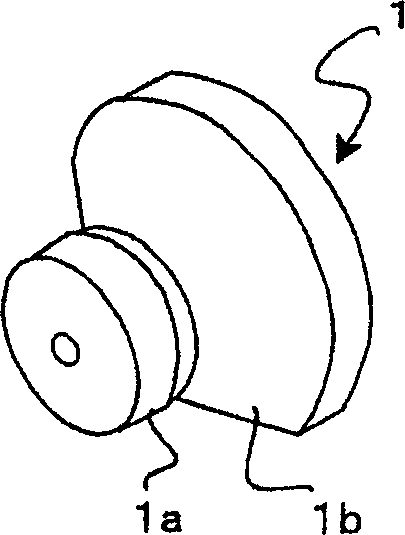

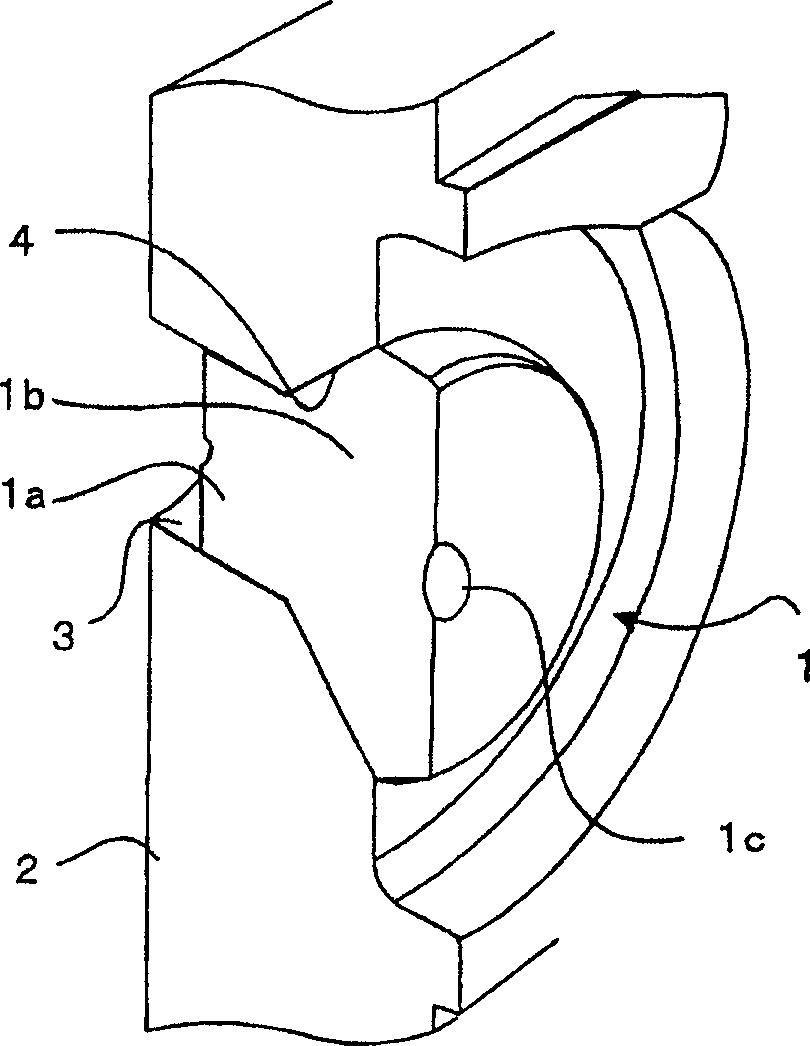

[0023] Figure 1a and 1b It is a perspective view of the alignment jig including the injection nozzle alignment device shown from different directions in the first embodiment of the present invention. The alignment jig 1 has a cylindrical portion 1a and a conical portion 1b coaxial with the cylindrical portion 1a and continuing from the cylindrical portion 1a, the conical portion 1b has a bottom surface (end facing the cylindrical portion) and A recess 1c is formed at the center of the bottom surface (on the axis of the cylindrical portion 1a and the conical portion 1b) and engages with the distal end of the injection nozzle. The recess 1c has a concave surface matched to the distal end of the injection nozzle so as to be in close contact with the distal end, and the size of the concave surface is slightly larger than that of the distal end of the injection nozzle.

[0024] On the other hand, the fixed platen 2 connected to the fixed mold half has a mounting hole for receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com