Differential tool anchor

A tool-anchor and differential technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of uniform tension of steel strands, many times of tensioning process, and difficult control, etc., and achieve simplified tensioning equipment, convenient operation, and accurate control of elongation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

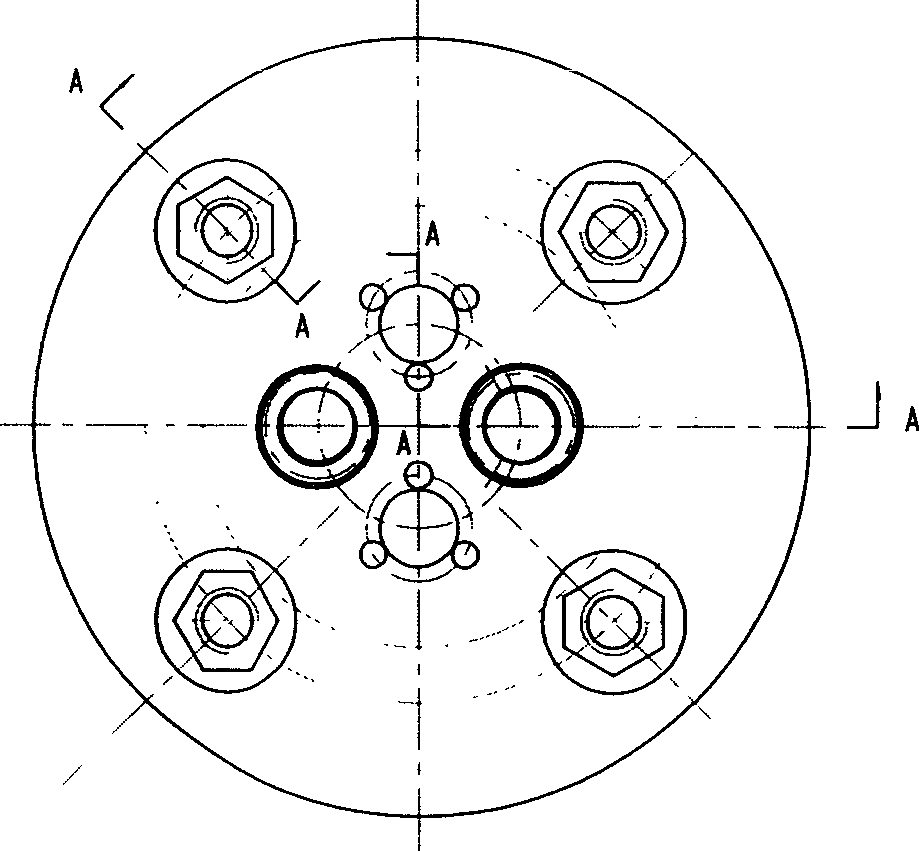

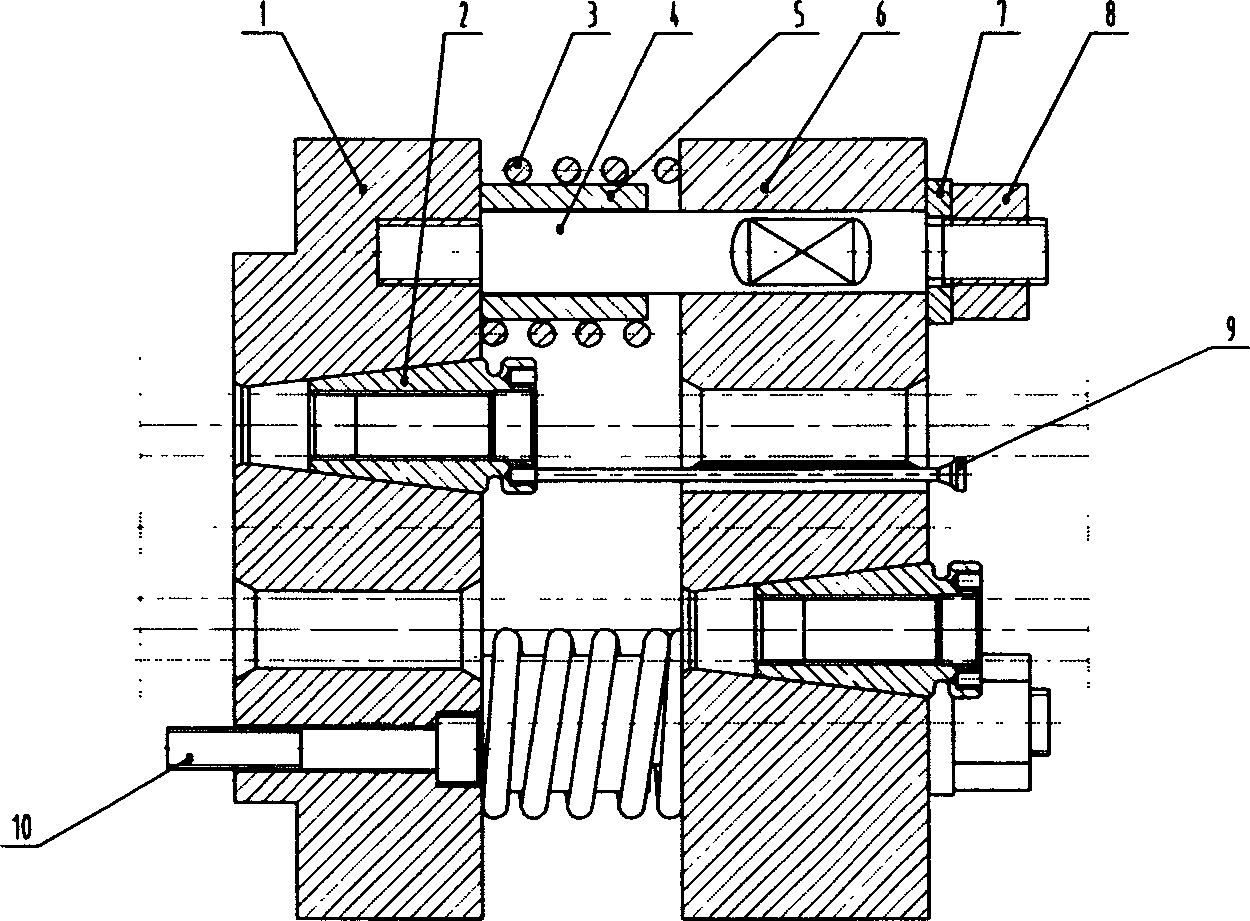

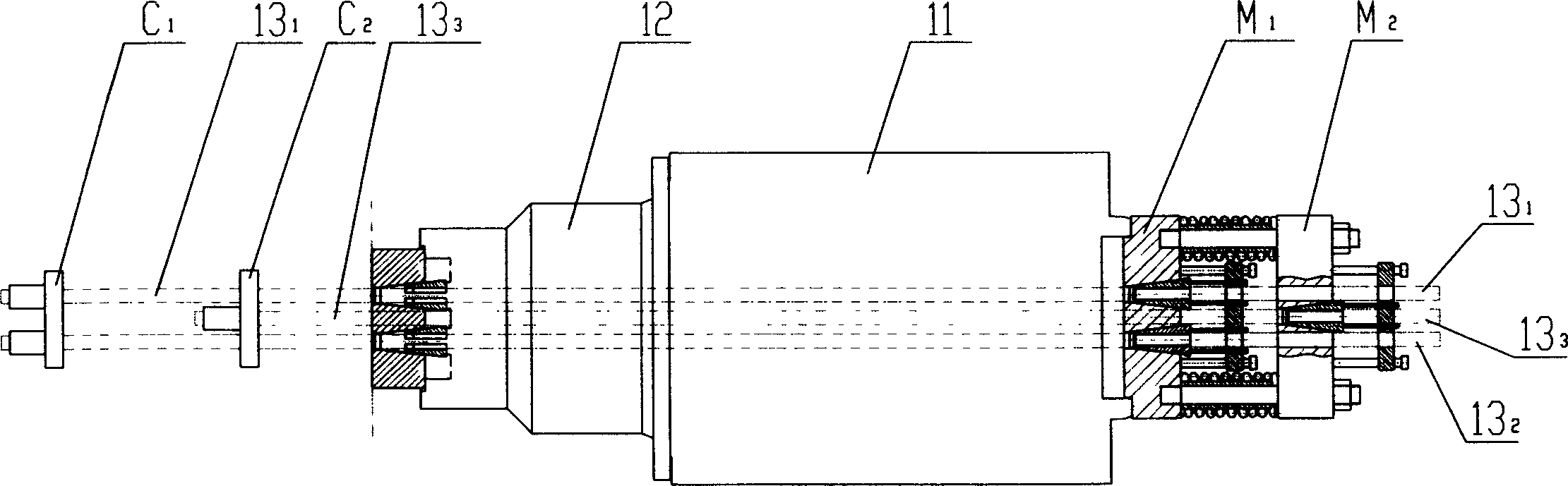

[0015] A differential tool anchor composed of two tool anchor components (see figure 1 , figure 2 ), including 2 tool anchor plate assemblies with tool clips, tool anchor plate M 1 With M 2 They are connected by a screw (4), and the ends are fastened with washers (7) and nuts (8). The screw (4) is partially covered by a spring (3) and a bushing (3) between every two tool anchor plates. 5) The tension stroke positioning block is formed, and each tool anchor plate has two anchor holes for anchoring the steel strand and two through holes for passing the steel strand; tool anchor plate M 1 (1) Positioning connection with tension jack through screws, tool anchor plate M 2 (6) Positioning is performed by a tension stroke positioning block composed of a spring (3) and a bushing (5), a washer (7), and a nut (8). Two tool anchor plates M 1 (1), M 2 (6) The length of the bushing (51) between (6) is less than the length of the spring, and the anchor plate M of the previous level tool 1 (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com