A kind of inner card jack and using method thereof

A technology of jack and inner diameter, which is applied in the processing of building materials, construction, lifting devices, etc., to achieve the effects of high force measurement accuracy, saving steel strands, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

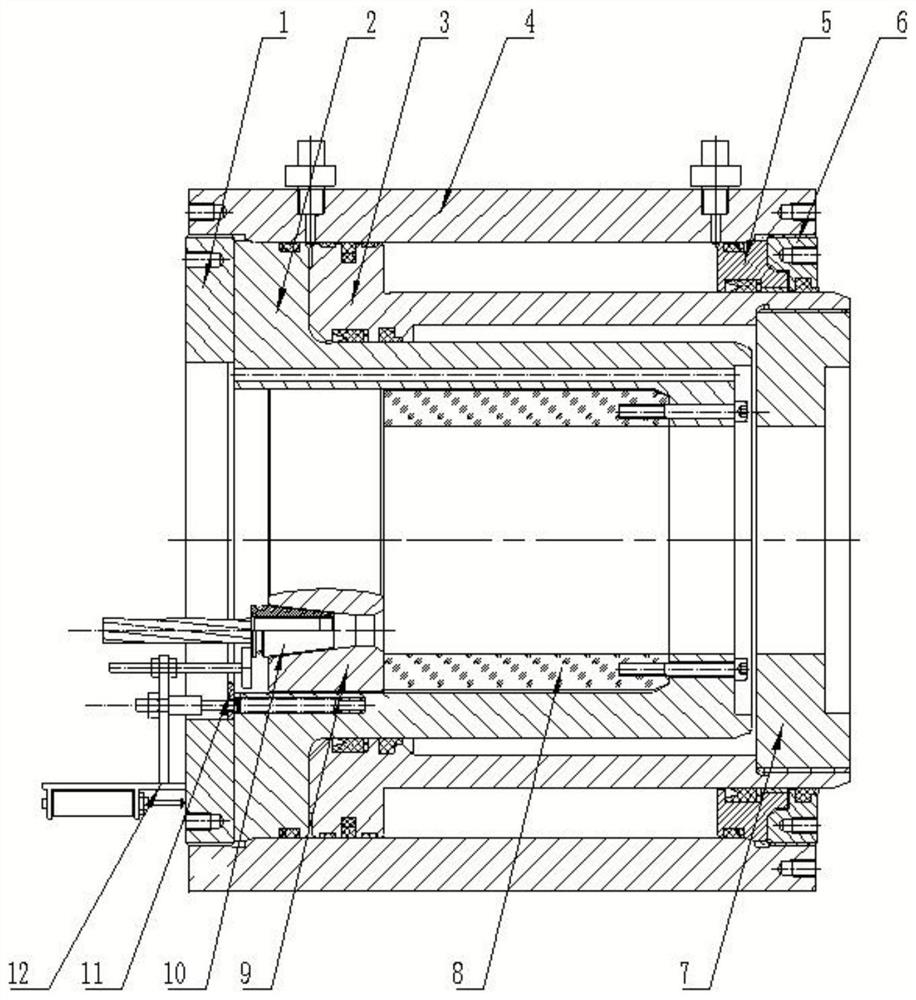

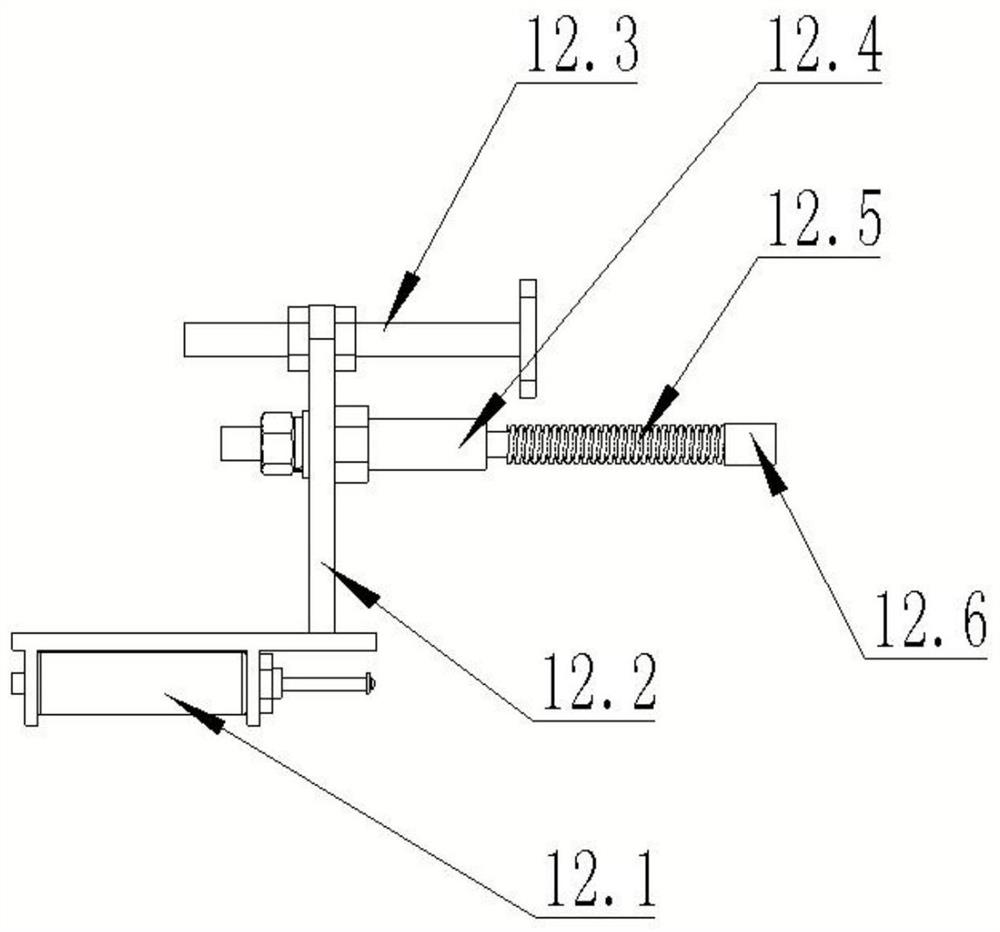

[0033] Such as Figure 1-Figure 2 As shown, it includes a positioning nut 1, a bushing 2, a piston 3, an oil cylinder 4, a top plate 7, a tool anchor plate 9 and a tool clip 10, the bushing 2 is located in the cylinder 4, and the left end of the bushing 2 is equipped with a positioning The nut 1 and the positioning nut 1 are hollow cylindrical, the top pressure plate 7 is installed on the right end of the through sleeve 2, the piston 3 is installed between the oil cylinder 4 and the through sleeve 2, the sealing plate 5 and the compression ring 6 are used as the sealing assembly from the inside to the outside Installed in the middle of the oil cylinder 4 and the piston 3 in turn, the tool anchor plate 9 is installed on the left end of the inner test of the through sleeve 2, the tool anchor plate 9 has a hole through which a single steel strand passes, and the tool anchor plate 9 is embedded with a tool clip 10 , the tool clip 10 is provided with holes for a single steel strand...

Embodiment 2

[0043] It includes a positioning nut 1, a bushing 2, a piston 3, an oil cylinder 4, a top pressure plate 7, a tool anchor plate 9 and a tool clip 10, the bushing 2 is located in the cylinder 4, and the left end of the bushing 2 is equipped with a positioning nut 1, The positioning nut 1 is a hollow cylinder, the top pressure plate 7 is installed on the right end of the bushing 2, the piston 3 is installed in the middle of the oil cylinder 4 and the bushing 2, the sealing plate 5 and the compression ring 6 are installed in sequence from inside to outside as sealing components. In the middle of the oil cylinder 4 and the piston 3, the tool anchor plate 9 is installed on the left end of the inner test of the through sleeve 2. The tool anchor plate 9 has a hole through which a single steel strand passes. The tool anchor plate 9 is inlaid with a tool clip 10, and the tool clip The sheet 10 is provided with holes for a single steel strand to pass through, and the number of the holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com