Phosphors for a plasma display panel, and a plasma display panel using the same

A plasma and display panel technology, applied in the field of phosphors, can solve problems such as reducing image brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

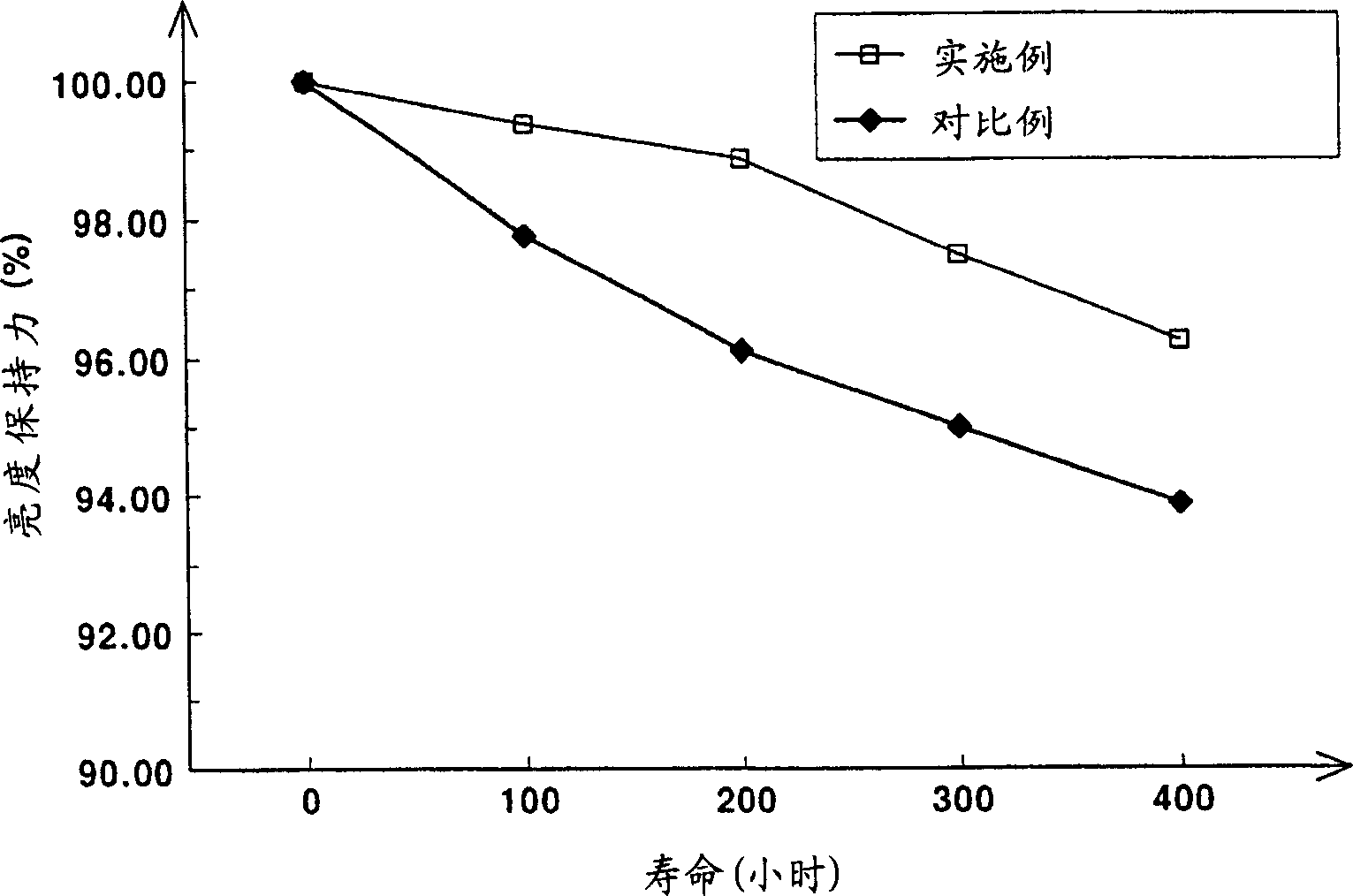

[0027]First dissolve the binder, nitroethyl cellulose ("NEC") in a solvent to provide an appropriate viscosity, then add optical initiators, multifunctional monomers and various additives to prepare a high molecular weight liquid solution. A fluorescent powder containing 20% by weight of MgO is added as the first non-fluorescent material to the high molecular weight liquid solution. The solution was then stirred with a high speed stirrer. Then, the phosphor powder is evenly dispersed by three rollers to form a photosensitive phosphor slurry while controlling the viscosity. The fluorescent paste is then coated between the barrier ribs and fired to make a PDP. Brightness was measured at 0 hours, 100 hours, 200 hours, 300 hours and 400 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com