Resonator with retention ribs

A resonator and resonant cavity technology, applied in the direction of intake mufflers, machines/engines, charging systems, etc., can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

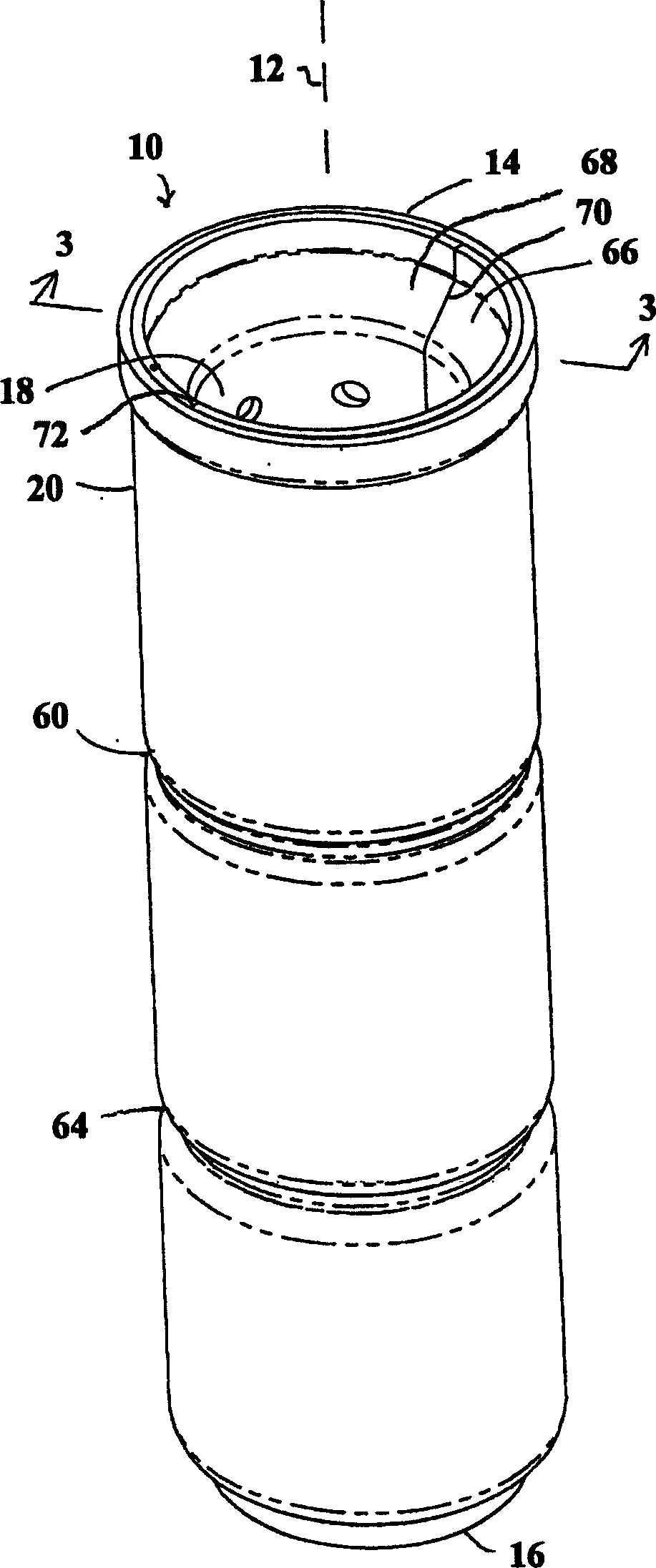

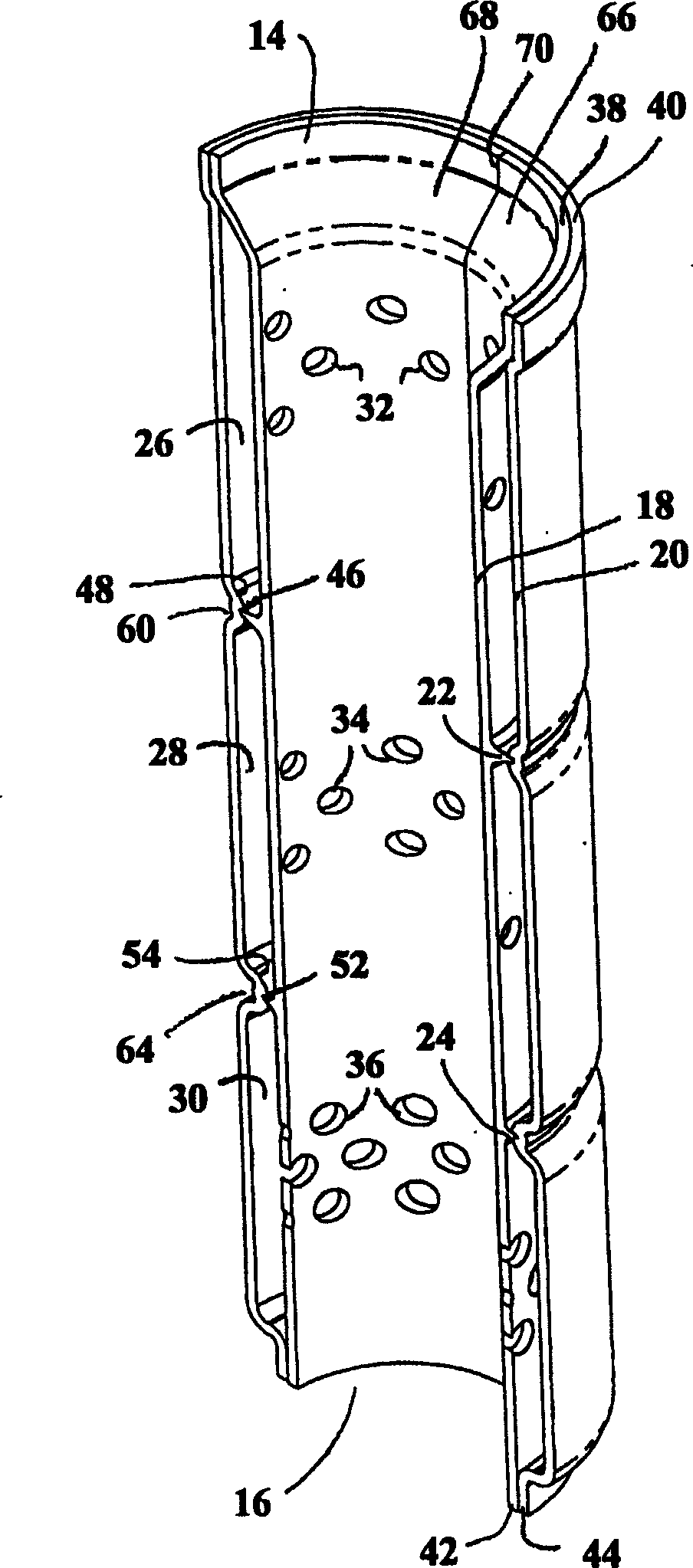

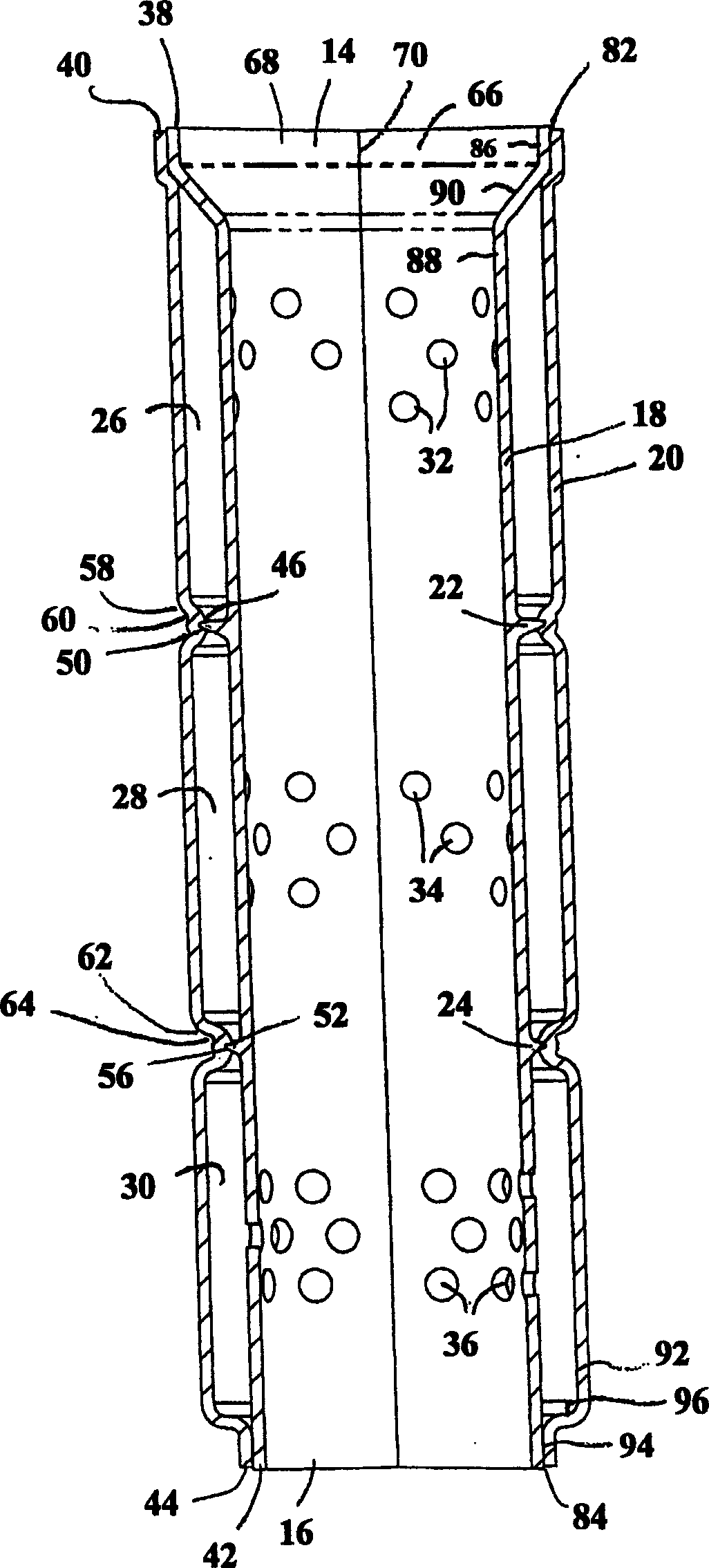

[0008] figure 1 Resonator 10 is shown extending along axis 12 between two axially opposite ends 14 and 16 which provide an inlet and an outlet respectively, such as at inlet 14 to receive drawn-in combustion air, Combustion air is delivered from outlet 16 to an internal combustion engine (not shown). Such as Figure 2-4 As shown, the resonator 10 has an inner porous tube 18, a housing 20 and at least one and preferably two or more annular ribs such as 22, 24 which are axially spaced between the inlet 14 and the outlet 16 and which are separated in the inner porous tube 18 and the shell 20 extend along the radial direction. In a preferred form, the inner perforated tube 18 is an injection molded piece of plastic and the outer shell 20 is a molded or rotationally molded piece of plastic, and the ribs are integral radially outwardly from the inner perforated tube 18 extend out. These ribs define a first resonant cavity 26 axially upstream of the rib 22, between the inner perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com