Method and device for separating gases and/or liquids

A kind of equipment and liquid technology, applied in the direction of separation method, chemical instrument and method, distillation separation, etc., can solve the problem of heat pump energy saving effect decline and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

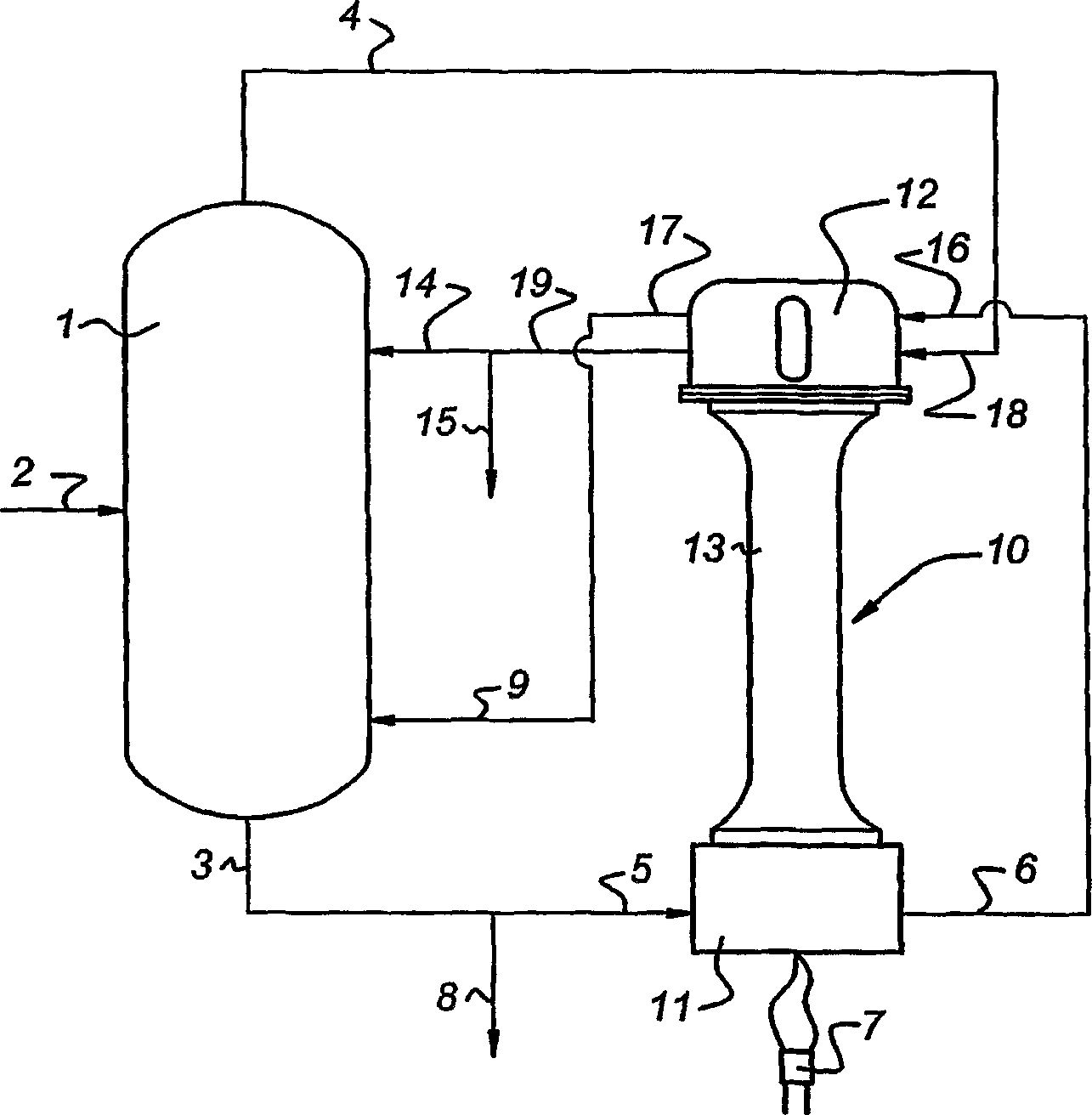

[0015] exist figure 1 In , the distillation column is indicated by reference numeral 1 . The distillation column is provided with an inlet 2 for the introduction of the product to be distilled. In addition, a bottom outlet 3 and a top outlet 4 are provided.

[0016] exist figure 1 In the example shown, the bottom outlet 3 is provided with a branch line 8 for withdrawing the bottom product, while some of the bottom product is fed into the low-temperature inlet 5 of the motor 11 of the thermoacoustic heat pump 10 . The thermoacoustic heat pump comprises a motor 11 and a pump 12 connected via a resonator 13 . The thermoacoustic heat pump can be any heat pump known in the art today. Sound waves are generated in the heat pump's motor. The sound waves can be generated in the motor by temperature differences. Said temperature difference is produced in the heat pump by the fact that the motor is provided with a burner 7 (hot part) and at a certain distance from it the cold flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com