Control of air conditioning cooling or heating coil

A technology of control components and headers, applied in heating methods, lighting and heating equipment, space heating and ventilation, etc., can solve the problems of time-consuming water side balance of cold water systems and affecting system performance, etc., to ensure load performance and controllability sex, guaranteed low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

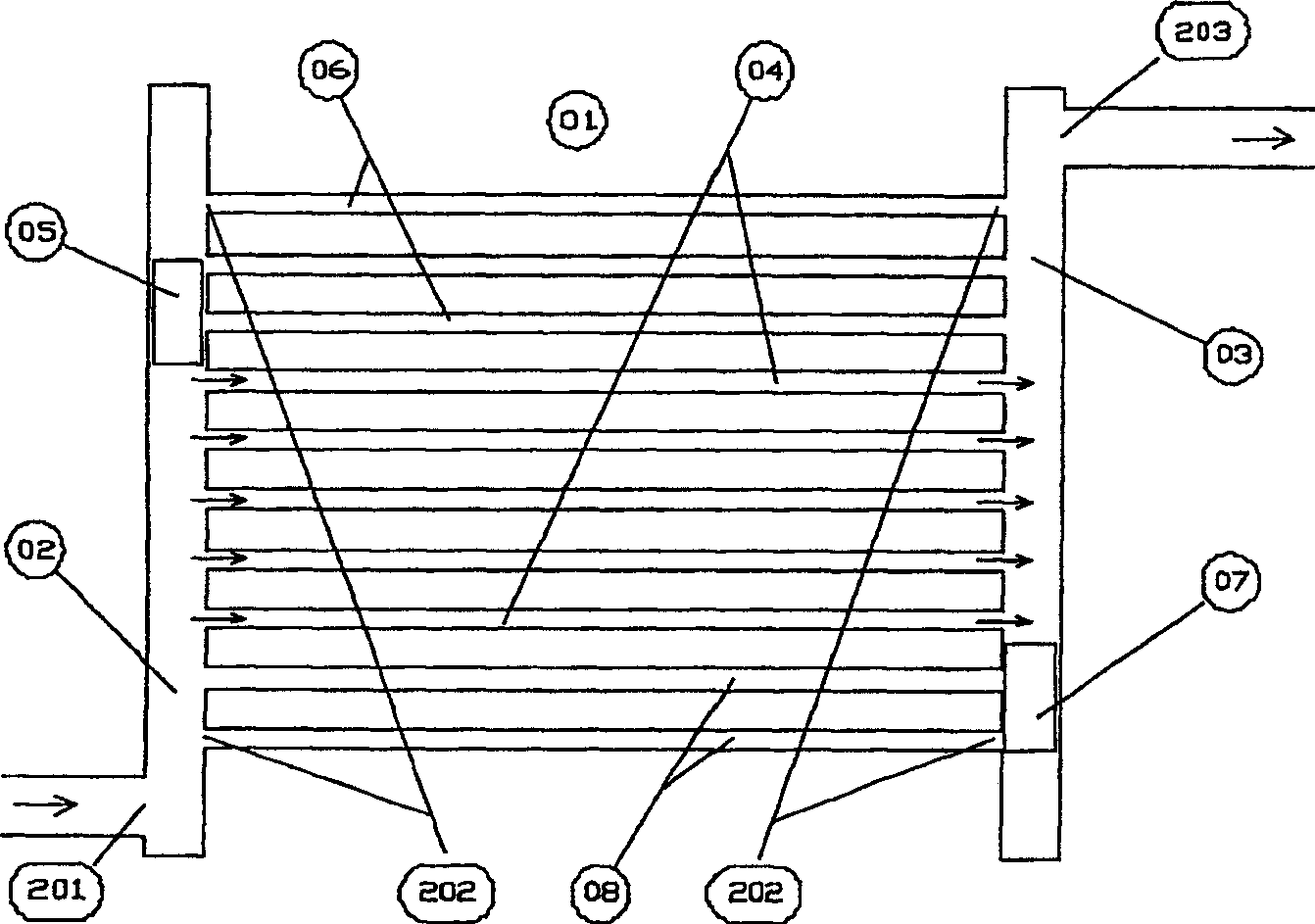

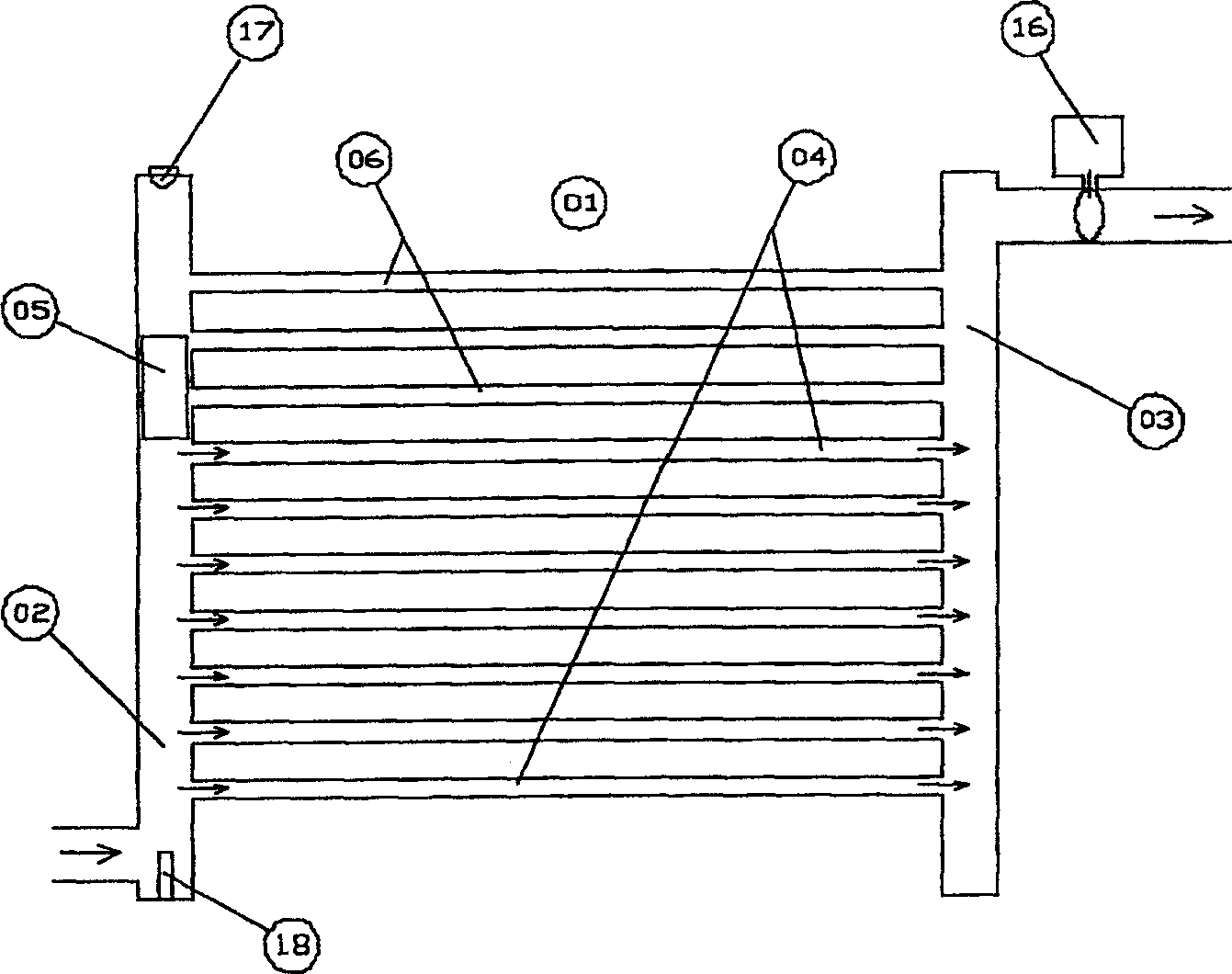

[0060] refer to figure 1 , The cold water coil 1 has a supply header 2, a return header 3 and an interconnection circuit 4 between the supply header and the return header. The plurality of interconnection circuits 4 are connected to the manifolds 2, 3 through corresponding plurality of connecting ports 202, the positions of the plurality of connecting ports 202 are different from each other and arranged in a line from top to bottom along the manifolds 2, 3. Row. The fluid flows into the supply header 2 through the supply port 201 at the bottom end of the header 2 and flows from the return header 3 through the return port 203 at the top end of the return header 3 . A sliding piston 5 is located in the supply manifold 2 and is equipped with a watertight seal to prevent the flow of water from the lower part to the upper part of this supply manifold 2 . In this figure, the piston 5 cuts off the water flow to the upper three circuits 6 where the coil surface temperature is the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com