Pressing lamp socket

A push-type, lamp holder technology, applied in the direction of incandescent lamps, discharge lamps, incandescent lamp parts, etc., can solve the problems of labor-intensive bulb replacement, lamp cap residue, time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

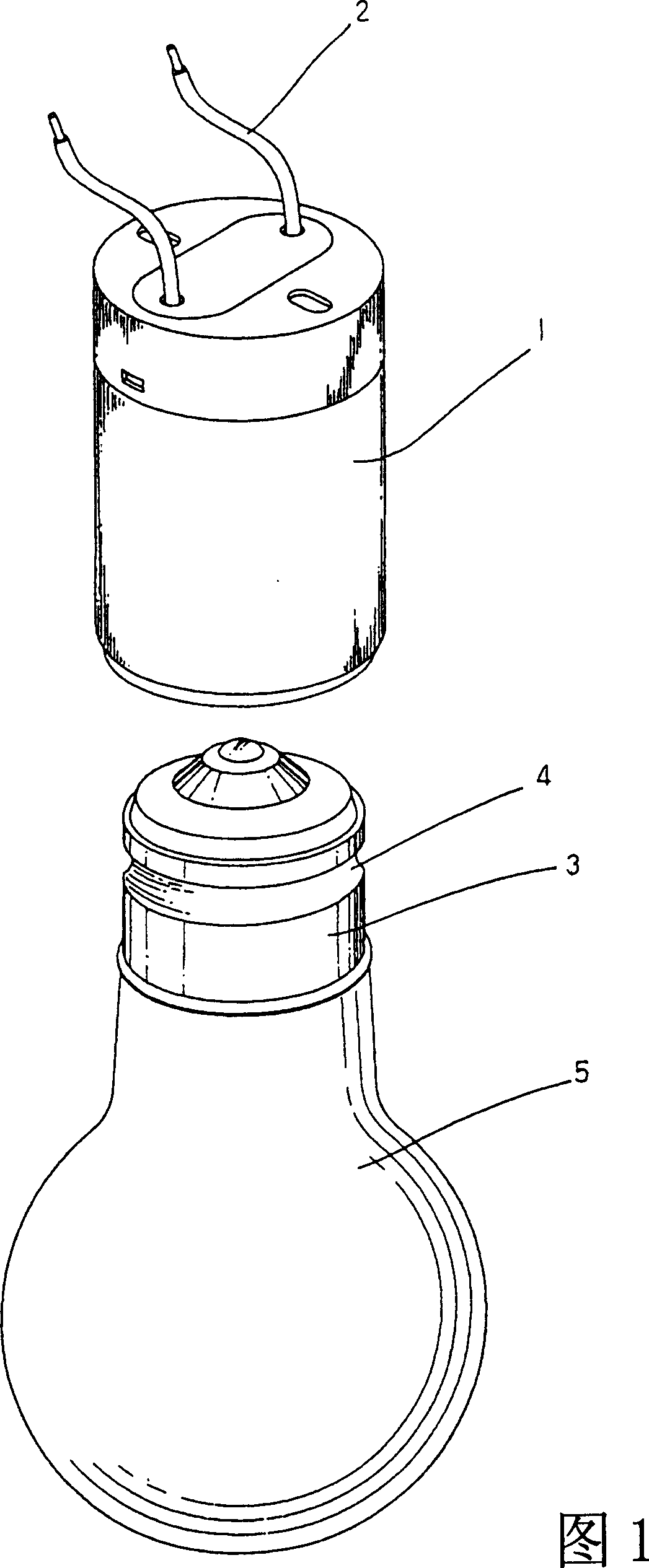

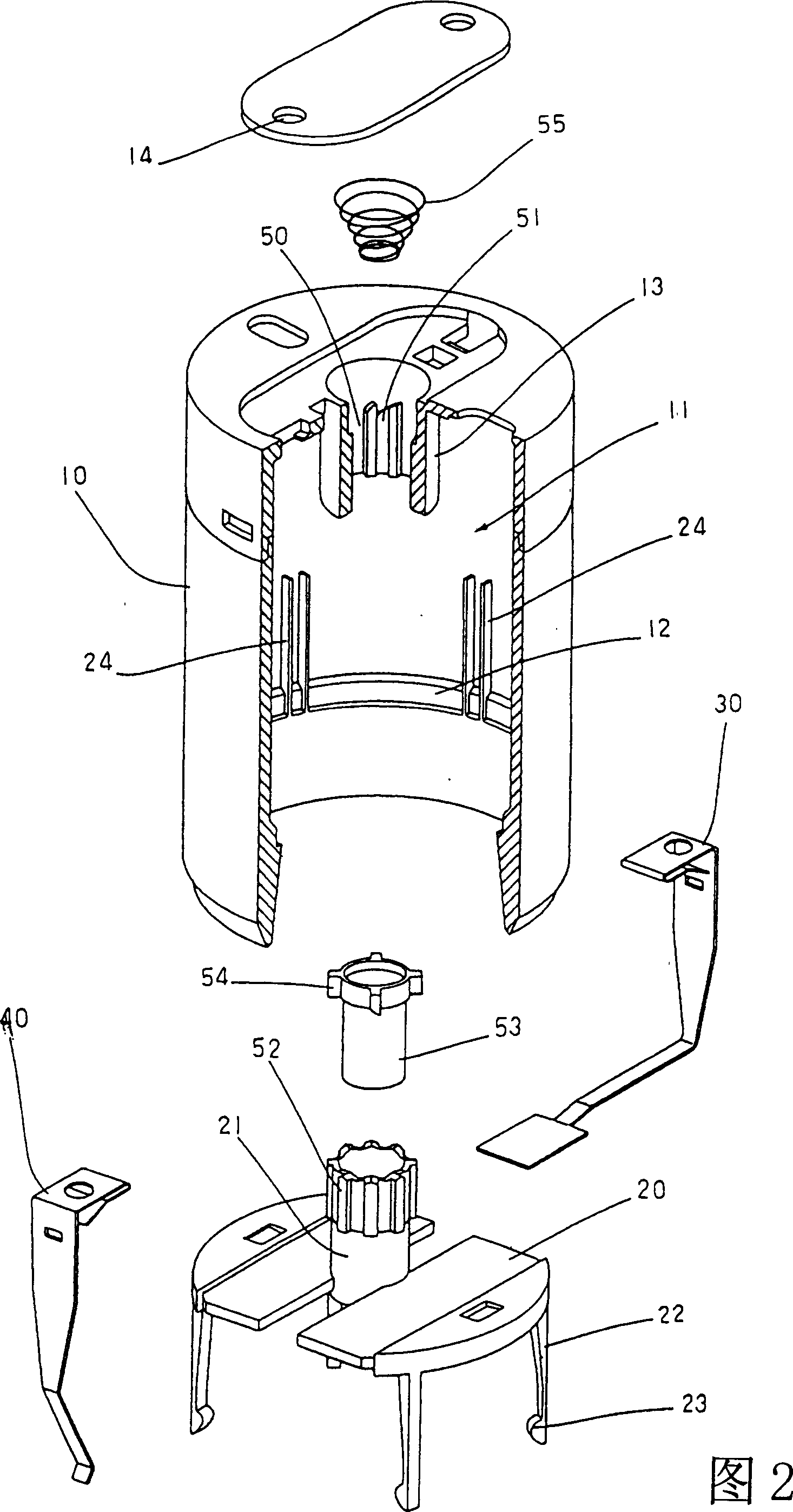

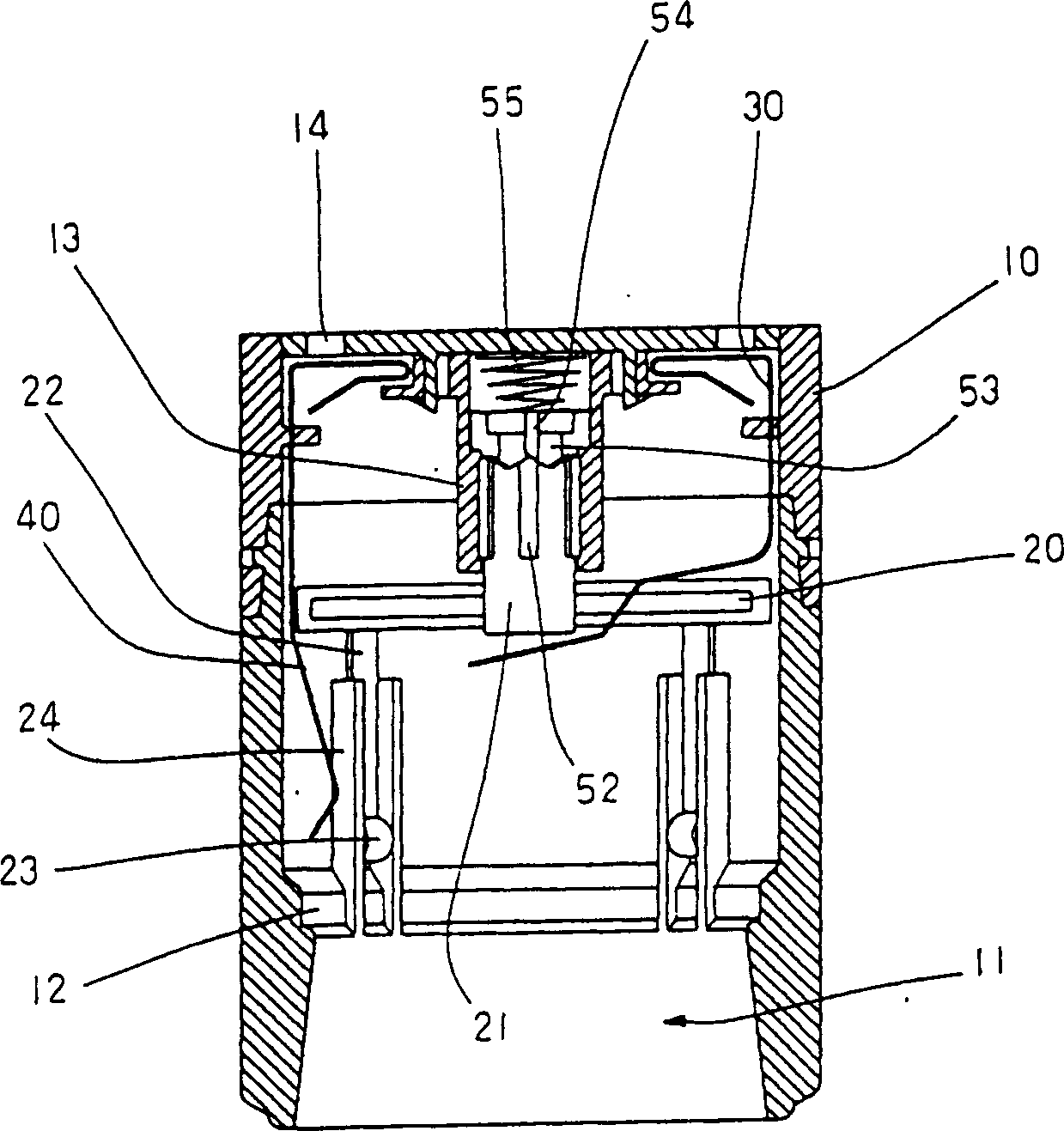

[0020] The present invention is a push-type lamp holder, as shown in Figure 1, its body 1 is set on one end of an electric wire 2, for installation and use of a light bulb 5 with a groove 4 on the surface of a lamp cap 3; and as shown in Figure 2 , which is mainly composed of an insulating shell 10, a first conductive sheet 30, a second conductive sheet 40, a clamping foot 20 and a pressing and clamping mechanism; see Fig. 2, image 3 As shown, wherein: the insulating casing 10 is a housing provided with a housing groove 11 for the movable entry and exit of the lamp cap of the bulb. The wall is provided with a sliding sleeve 13 for restricting the axial movement of the clamping foot 20, and a pair of wire perforations 14 are provided on the wall at both sides of the sliding sleeve; the clamping foot 20 is formed by a sliding sleeve that can move up and down Brake pipe 21 and be connected at the bottom of brake pipe and can be attached to the several equal-length feet 22 that mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com