Peanut straw seedling growing medium special for vegetables and preparing method of peanut straw seedling growing medium

A technology for peanut straw and seedling-raising substrate, which is applied to the field of peanut straw seedling-raising substrate and its preparation, can solve the problems of unfavorable popularization and application, waste of organic resources and high cost, so as to avoid excessive soil salinity, long-lasting and slow fertilizer effect release, and fertilizer utilization rate. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

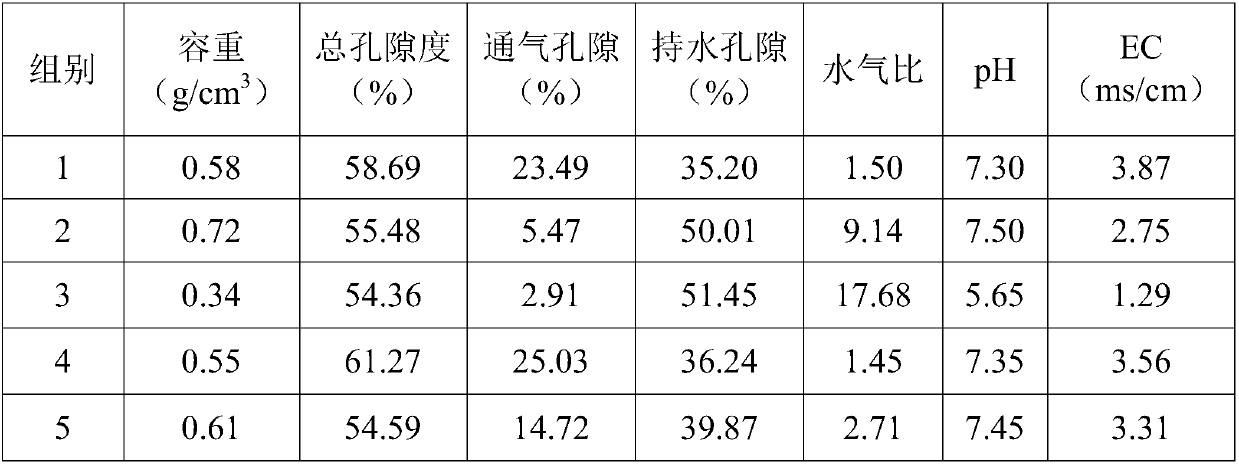

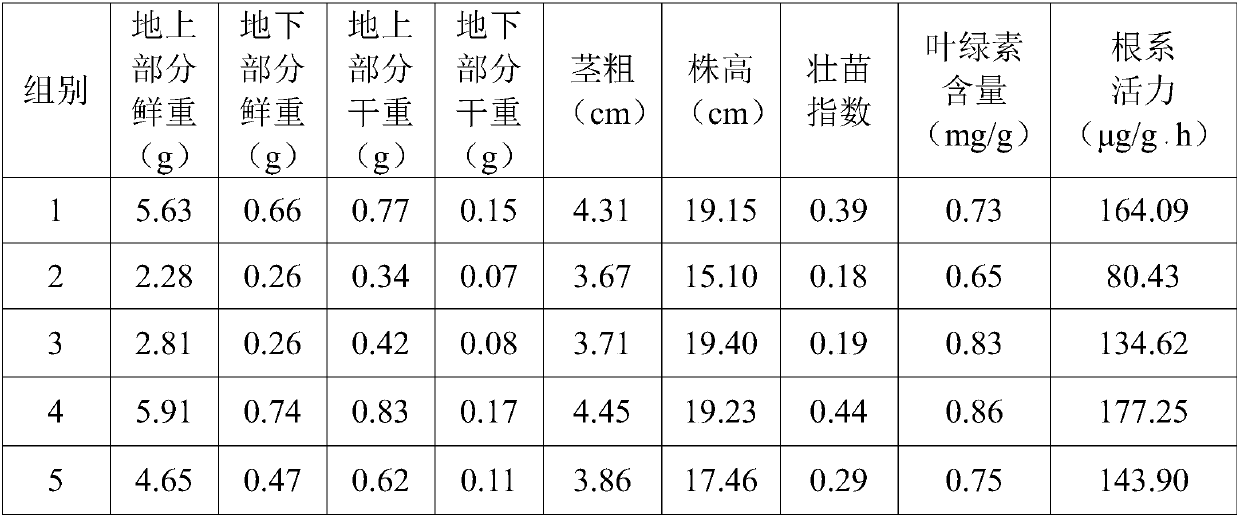

Embodiment 1

[0045] A peanut straw seedling raising substrate is made from the following raw materials in parts by volume:

[0046] Peanut straw 80; garden soil 20.

[0047] The preparation method is as follows:

[0048] (1) Peanut stalk decomposing treatment: crush the peanut stalks into particles with a diameter of 0.1-0.3 cm, add 2.0 times the amount of water to it, and simultaneously add a straw decomposing agent equivalent to 0.2% of the total weight of the peanut stalks, and the stalks are decomposed The agent is prepared by the ratio of starter: brown sugar: water = 1:1:20. It is activated for 12 hours before use, and the above-mentioned peanut straw particles, water and straw decomposing agent are fully mixed to obtain a straw premix, and the straw premix is controlled. The moisture content of the material is 60-65%; the above-mentioned straw premix is stacked up, sealed with a plastic film, turned every 7-10 days, and an equivalent amount of other straw is added to the straw ...

Embodiment 2

[0053] A peanut straw seedling raising substrate is made from the following raw materials in parts by volume:

[0054] Peanut straw 75; garden soil 18.

[0055] The preparation method is as follows:

[0056] (1) Peanut stalk decomposing treatment: crush the peanut stalks into particles with a diameter of 0.1-0.3 cm, add 1.8 times the amount of water to it, and simultaneously add a straw decomposing agent equivalent to 0.3% of the total weight of the peanut stalks, and the stalks are decomposed The agent is prepared by the ratio of starter: brown sugar: water = 1:1:20. It is activated for 8 hours before use, and the above-mentioned peanut straw particles, water and straw decomposing agent are fully mixed to obtain a straw premix, and the straw premix is controlled. The moisture content of the material is 60-65%; the above-mentioned straw premix is stacked up, sealed with a plastic film, turned every 7-10 days, and an equivalent amount of other straw is added to the straw p...

Embodiment 3

[0059] A peanut straw seedling raising substrate is made from the following raw materials in parts by volume:

[0060] Peanut straw 85; garden soil 22.

[0061] The preparation method is as follows:

[0062] (1) Peanut straw decomposing treatment: crush the peanut straw into particles with a diameter of 0.1-0.3 cm, add 2.0 times the amount of water to it, and simultaneously add a straw decomposing agent equivalent to 0.1% of the total weight of the peanut straw, and the straw is decomposed The agent is prepared by the ratio of starter: brown sugar: water = 1:1:20. It is activated for 24 hours before use, and the above-mentioned peanut straw particles, water and straw decomposing agent are fully mixed to obtain a straw premix, and the straw premix is controlled. The moisture content of the material is 60-65%; the above-mentioned straw premix is stacked up, sealed with a plastic film, turned every 7-10 days, and an equivalent amount of other straw is added to the straw prem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com