Board picking up apparatus and method for use therewith

A kind of equipment and board box technology, applied in the field of board picking equipment, can solve the problems of impossible picking, no suction cup adsorption, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

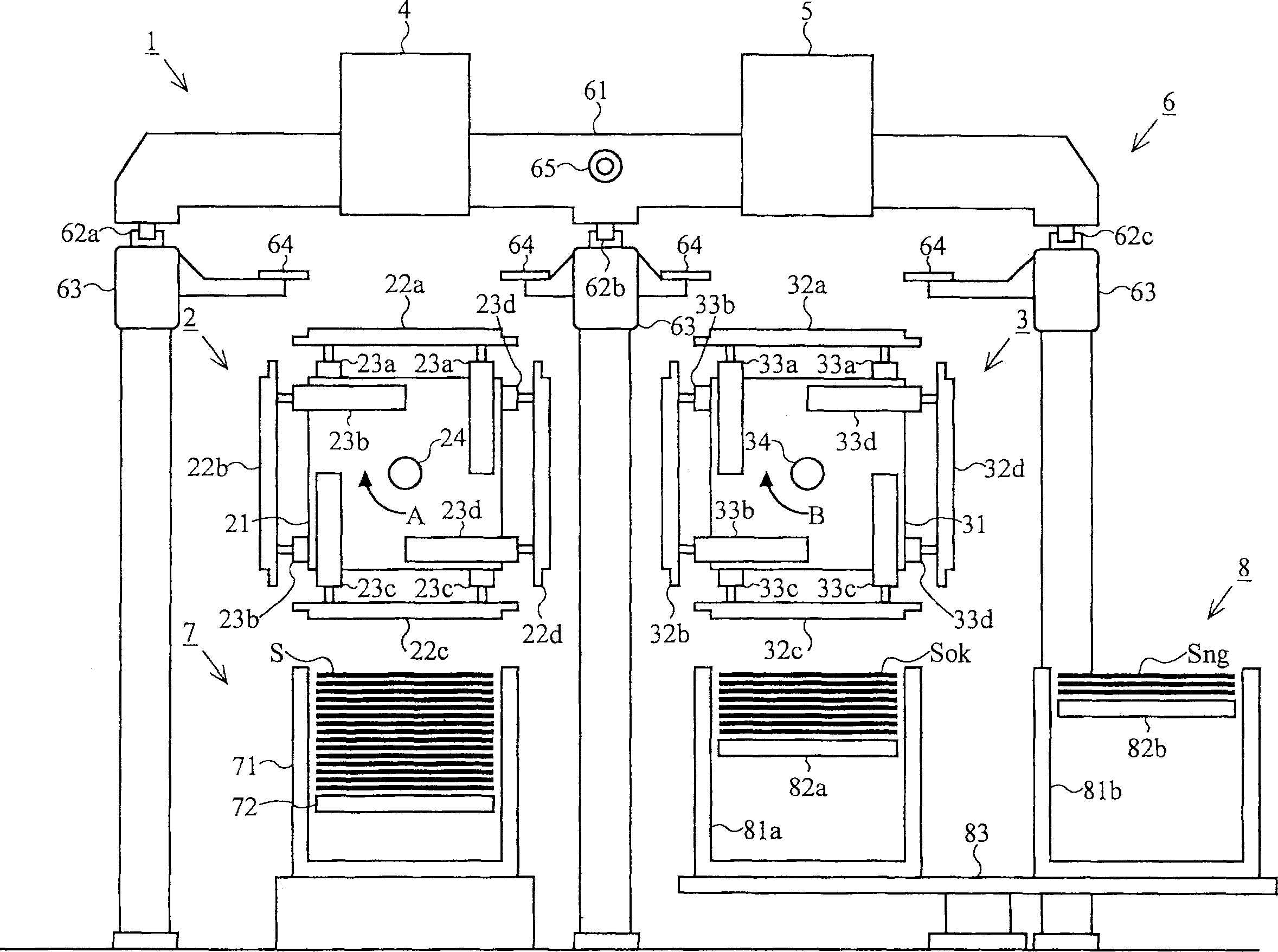

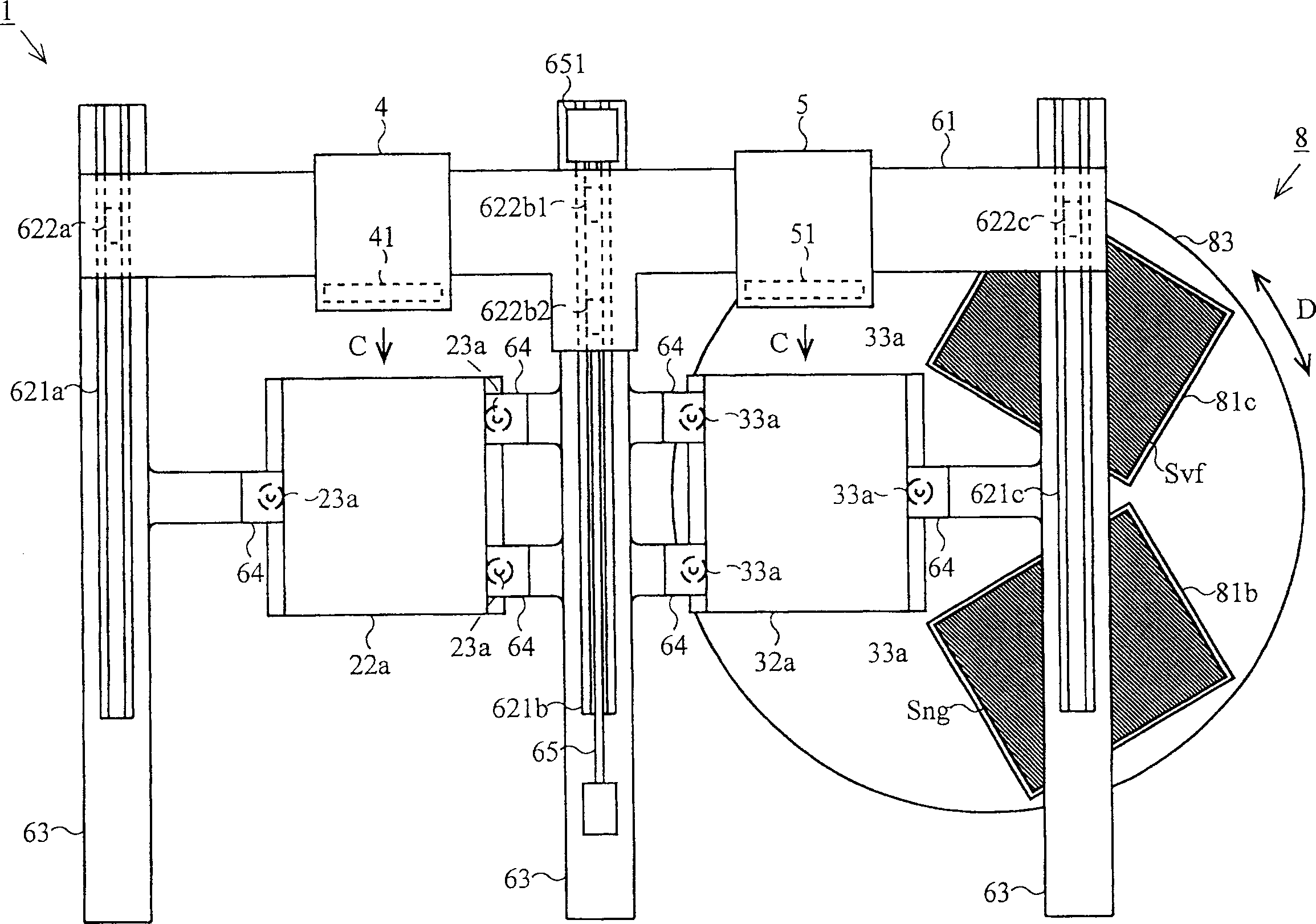

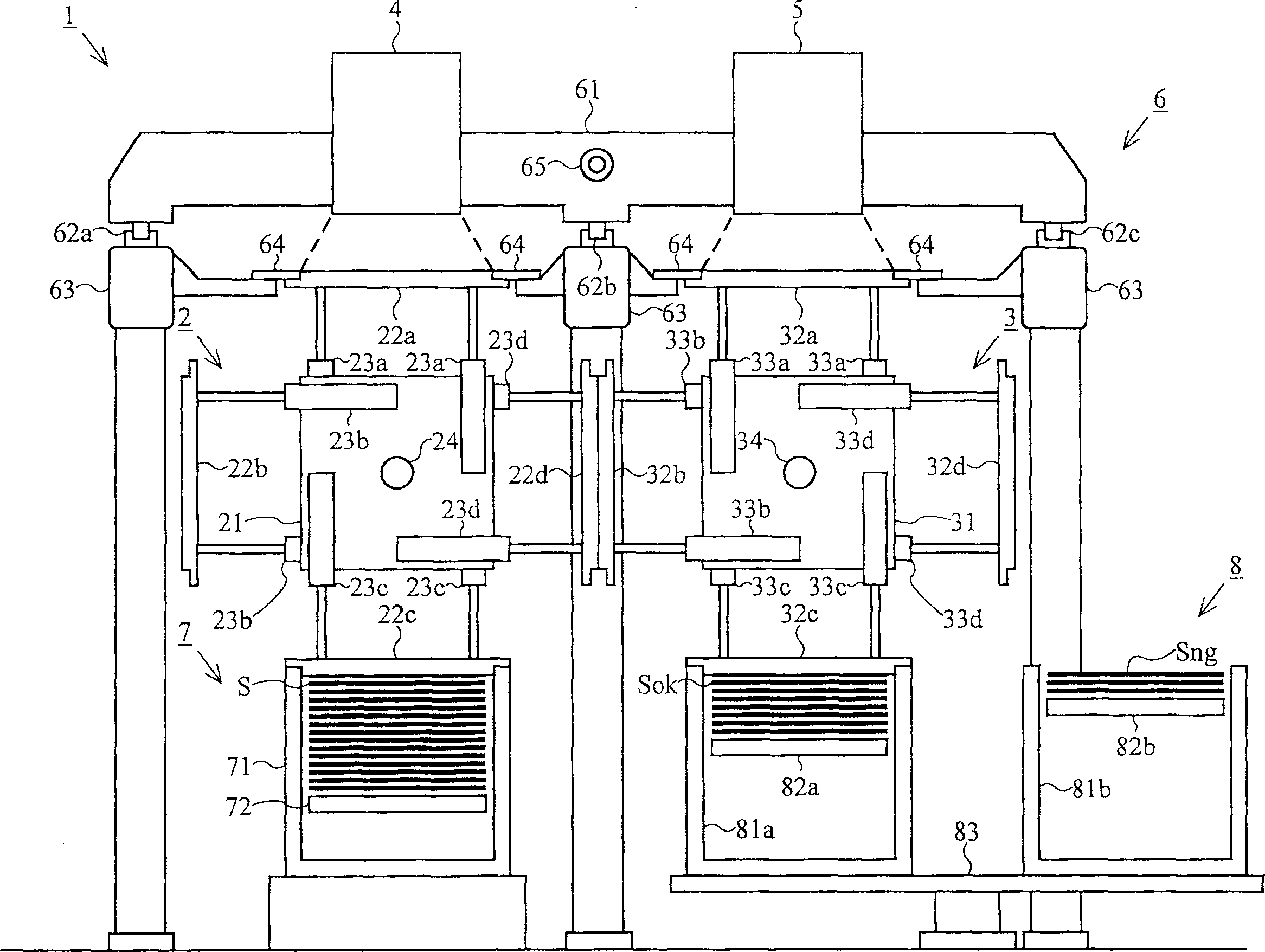

[0058] reference Figure 1 to Figure 5 , The board inspection apparatus 1 according to an embodiment of the present invention will be explained. figure 1 It is a front view showing a schematic structure of the board inspection apparatus 1. figure 2 It is a top view showing the schematic structure of the board inspection apparatus 1. image 3 It is a front view showing a schematic structure of the board inspection apparatus 1 having an expansion cylinder. Figure 4 It is a side view showing a schematic internal structure of the pneumatic mechanism of the panel inspection apparatus 1. Figure 5 It is a rear view showing the rotation driving mechanism for the rotating member of the rotating plate inspection apparatus 1. In order to clearly illustrate the positional relationship of the components, Figure 1 to Figure 5 Not all the constituent members of the board inspection apparatus 1 are shown.

[0059] in figure 1 Among them, the board inspection equipment 1 includes: a first in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com