Technique for producing recycled article by employing pouring molding of molten waste plastic

A technology for casting and molding waste plastics, used in the field of manufacturing recycled products, can solve the problems of waste not being a new product, difficult to sell, and appearance contamination, and achieve the effects of easy shrinkage of molten resin, prevention of workability decline, and shortening of the manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

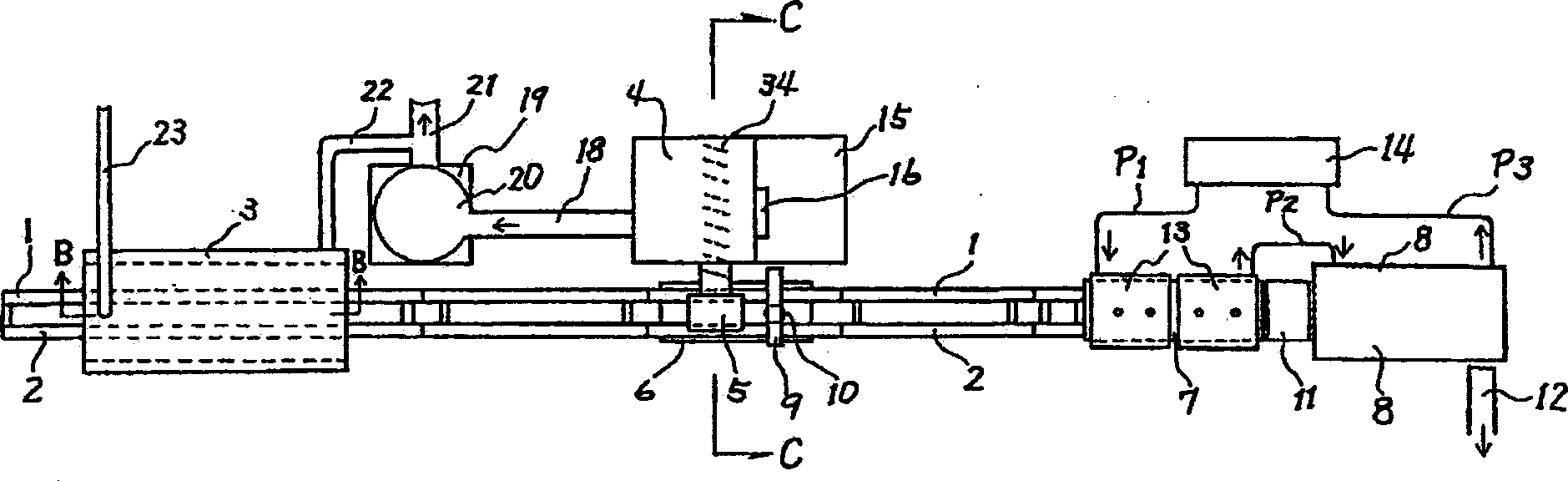

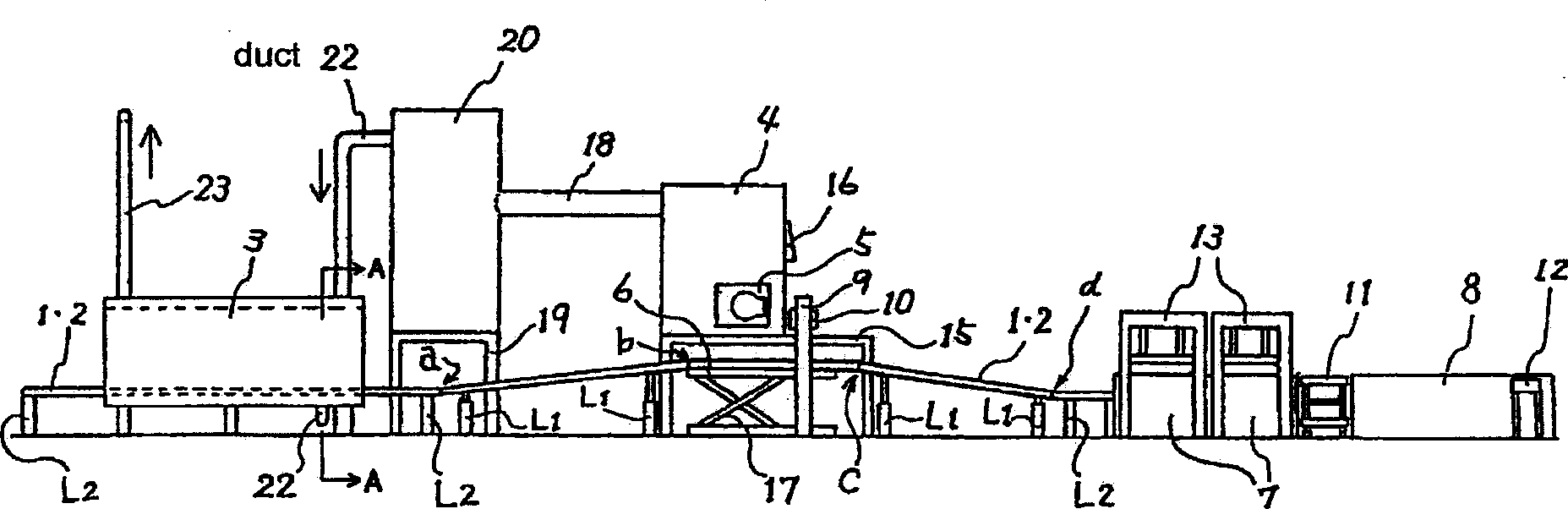

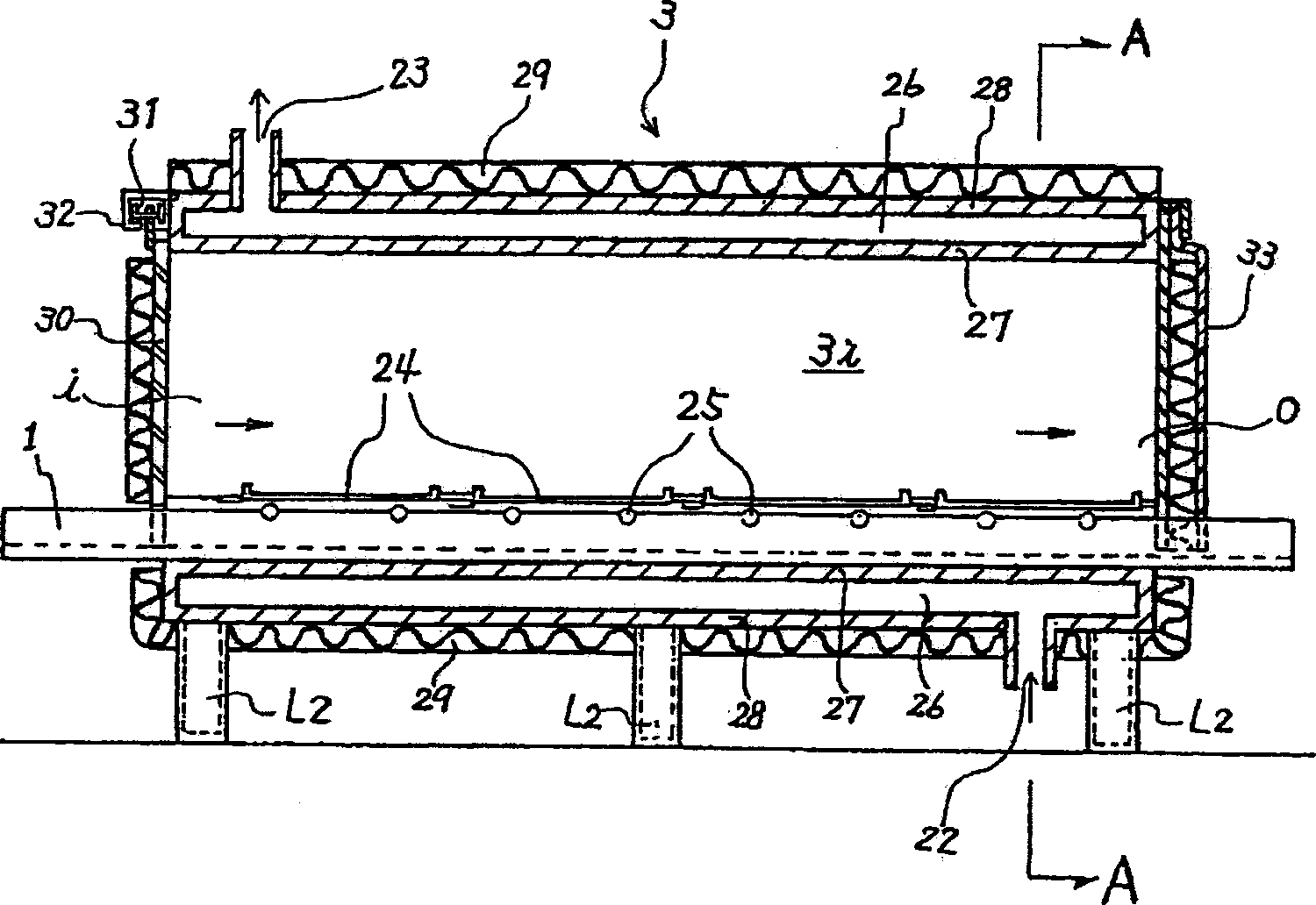

[0095] Hereinafter, specific embodiments of the manufacturing technology of cast-molded recycled products of waste plastics according to the present invention will be described in detail and how they are actually embodied, and the embodiments will be described. figure 1 , figure 2 It is the whole picture of the production line of the present invention, figure 1 is the floor plan, figure 2 is the front view.

[0096] The rails of two types of section steel 1 and 2 arranged in parallel are laid in the left and right directions, and the heating chamber 3 at the left end, the melting machine 4 in the middle, the storage heating and unloading equipment 5 and the up and down moving table 6 are arranged, and the primary heating chamber at the right end Cooling pool 7 and secondary cooling pool 8.

[0097] When the trolley carrying the metal mold was sent into the heating chamber 3 from the left end of the track, the metal tool was heated in the heating chamber 3, and the trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com