Chaotic control method in monitoring on-line state of large centrifugal fan

A centrifugal fan and fan technology, which is used in the testing, measuring devices, instruments and other directions of machines/structural components, and can solve problems such as misalignment, power failure, and imbalance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

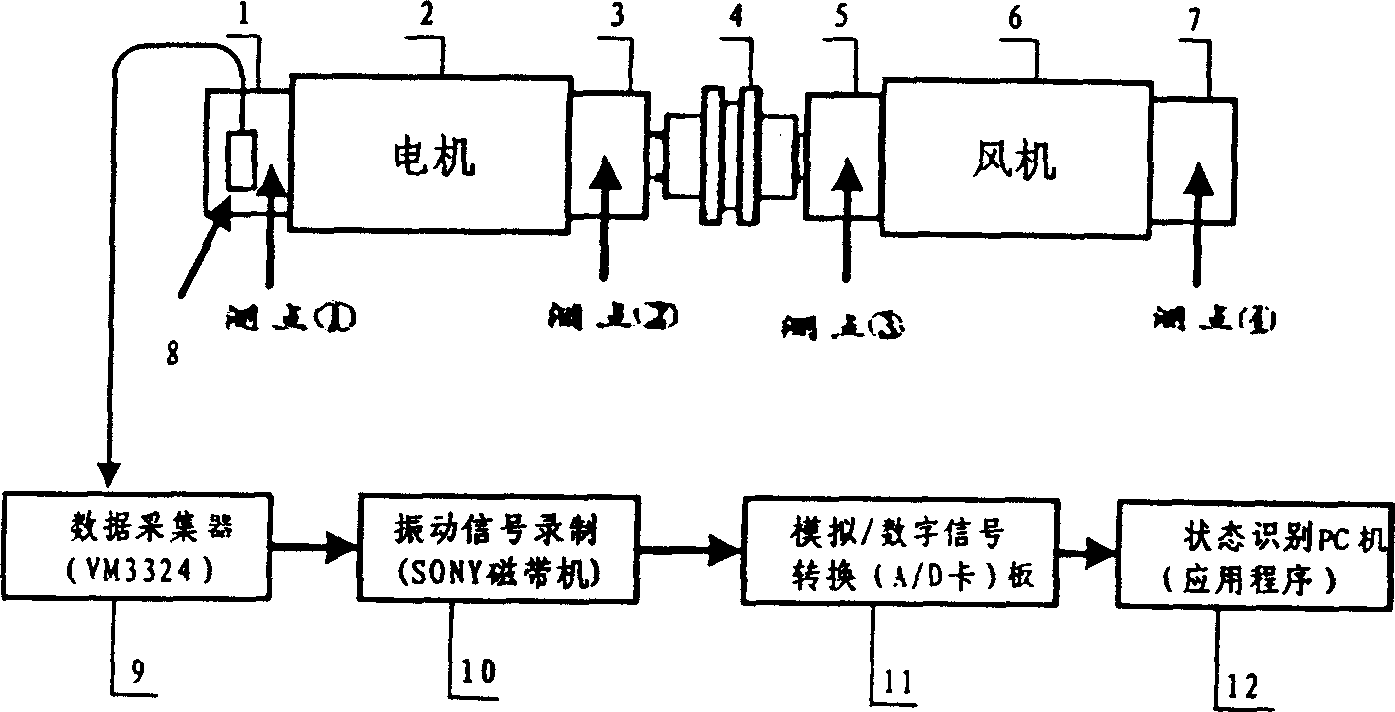

[0093] Please refer to the attached figure 1 , 2 , 3, shown in 4, the present invention is made up of parts such as motor, bearing block, shaft coupling, blower fan, sensor, tape drive, data collector and A / D conversion board, and one side of its motor (2) is free from motor The side bearing seat (1) is connected, the other side is connected with the motor load side bearing seat (3), one side of the fan (6) is connected with the fan load side bearing seat (5), and the other side is connected with the fan load side bearing seat (5). The bearing housing (7) on the free side is connected, and the bearing housing (3) on the load side of the motor and the bearing housing (5) on the load side of the fan are connected by a coupling (4);

[0094] One end of the data collector sensor (8) is installed on the free side bearing housing (1) of the motor, and its other end is connected with the input end of the data collector (9) module, and the output end of the data collector (9) module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com