Light source assembling structure

A technology of assembling structure and light source, which is applied in the parts and electrical components of TV and color TV, can solve the problems of inconvenient operation process and reduce product reliability, and achieve the effect of improving assembly performance and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

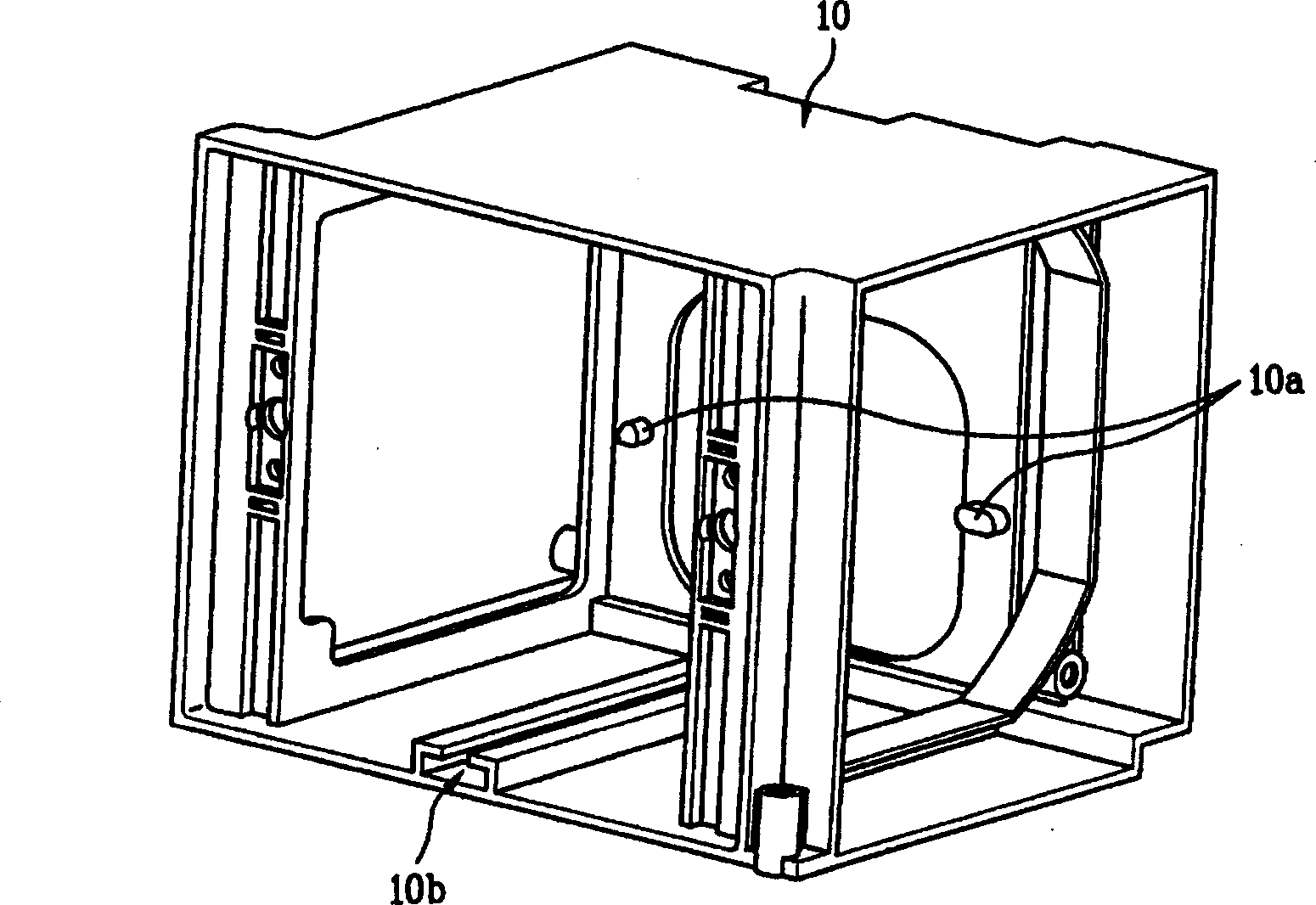

[0025] Next, the assembly structure of the light source assembly of the present invention will be described in further detail with reference to the accompanying drawings.

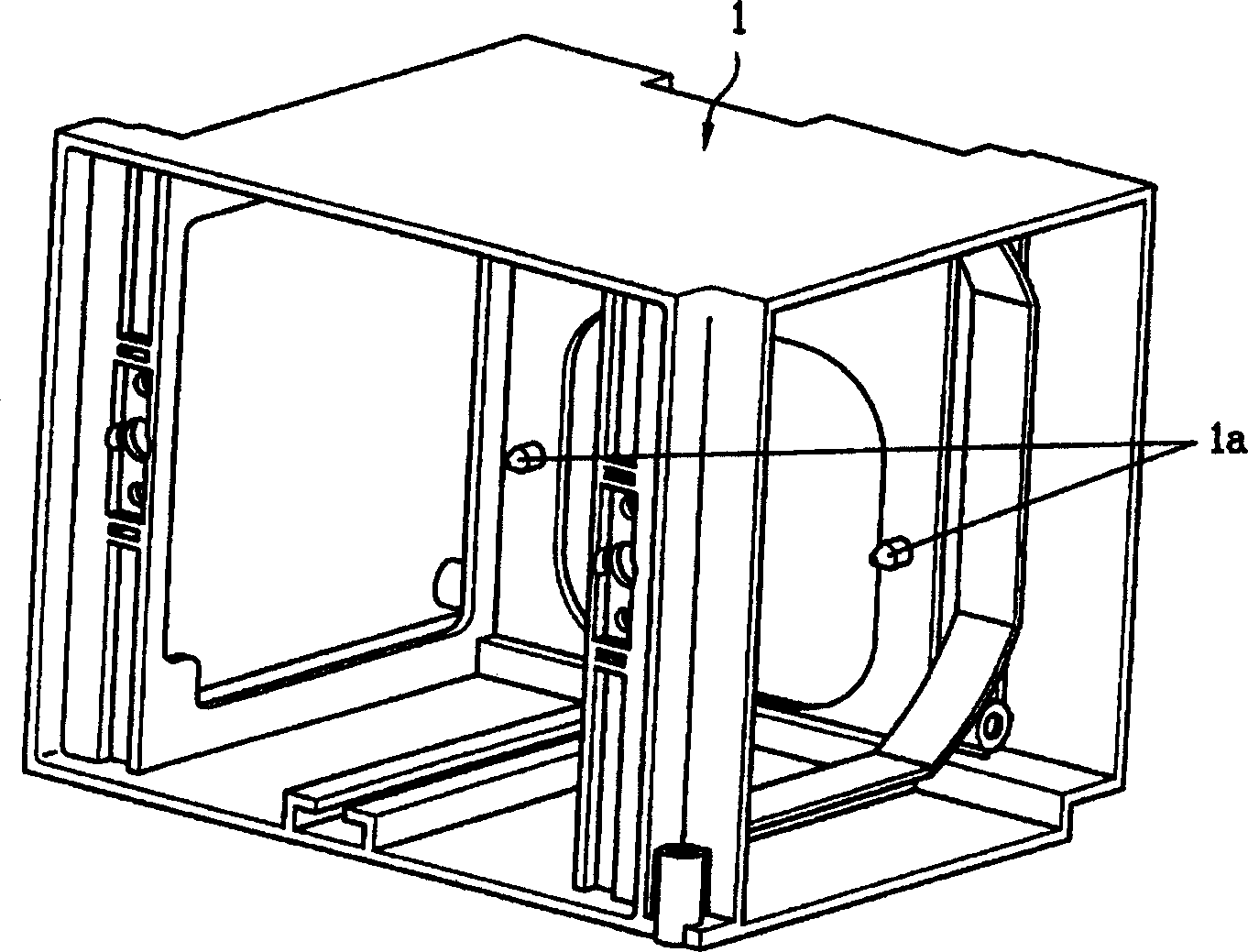

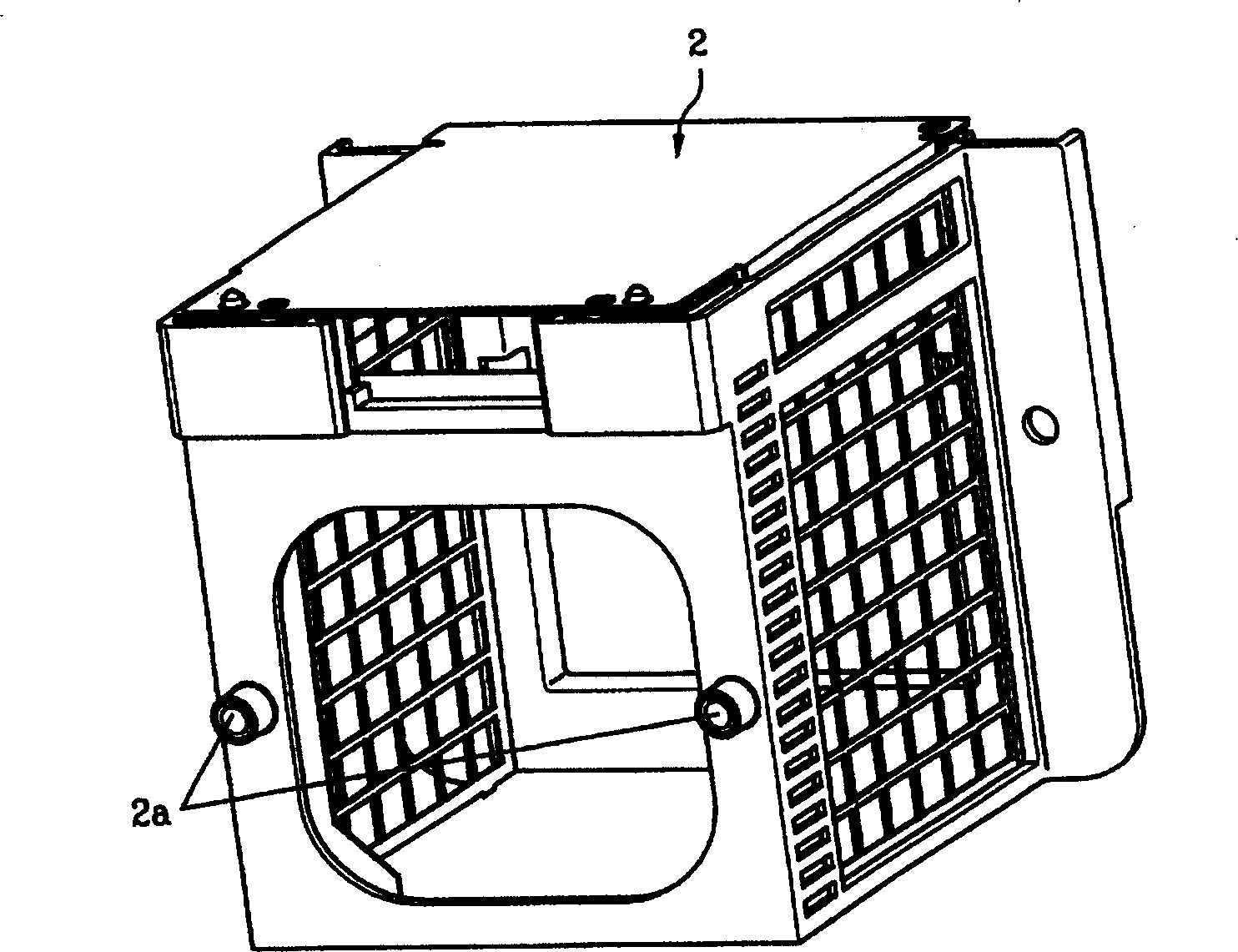

[0026] image 3 It is a perspective view of the light source bracket constituting the light source assembly of the present invention; Figure 4 It is a rear perspective view of the light source box constituting the light source assembly of the present invention.

[0027] The light source assembly structure of the present invention has the following structure, namely: a light source (not shown) that emits light is provided; a light source box 20 supporting the light source is provided; a light source bracket 10 that fixes and supports the light source box 20 is provided .

[0028] In addition, the light source bracket 10 is provided with protruding assembly guide posts 10a for fixing the light source box 20 on the left and right sides of its inner wall. The light source box 20 is provided with protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com