Negative pressure regulating structure of vortex compressor

A technology of scroll compressor and adjustment structure, applied in the field of scroll compressors, can solve problems such as component deformation and oil leakage, and achieve the effect of improving efficiency and preventing excessive leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

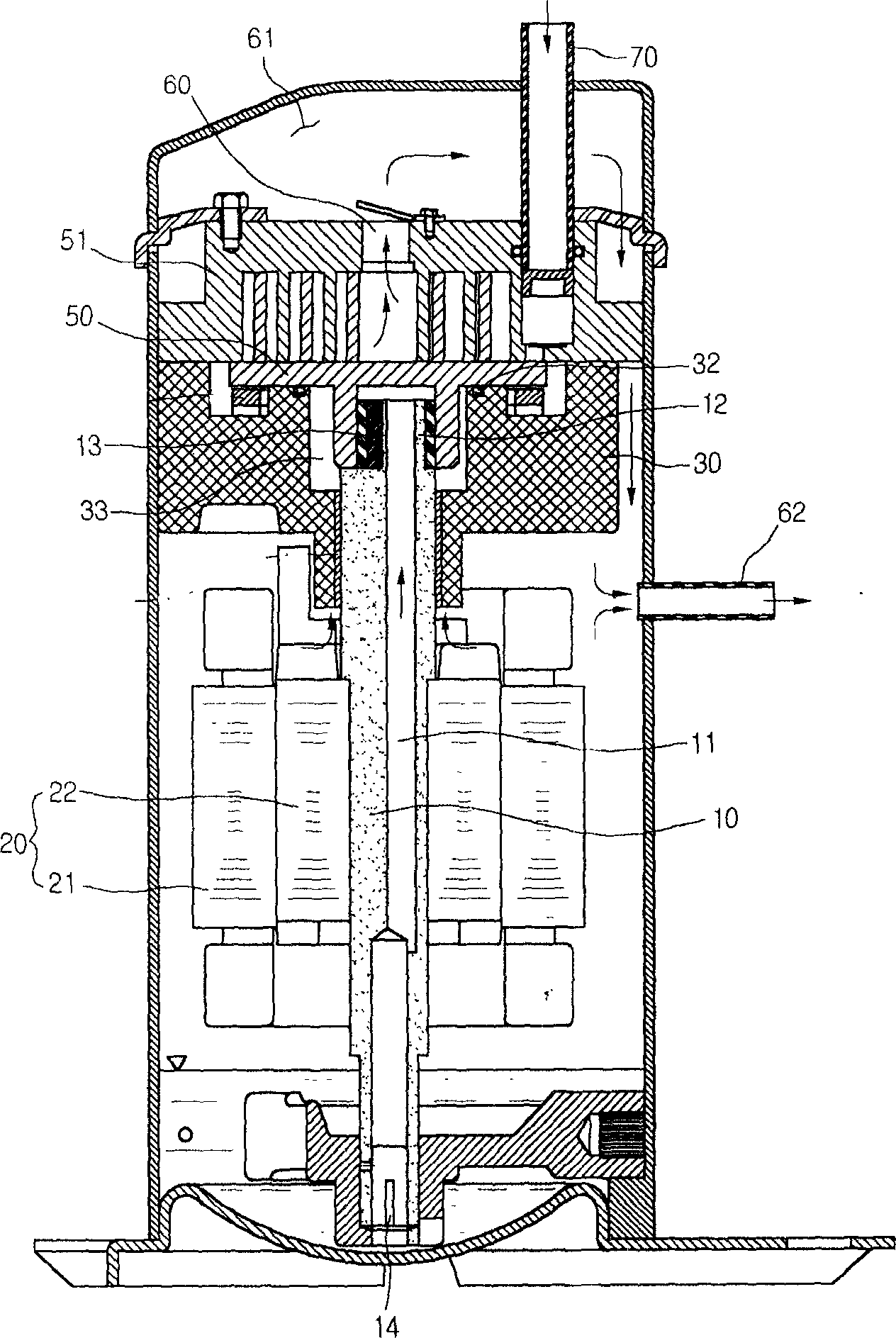

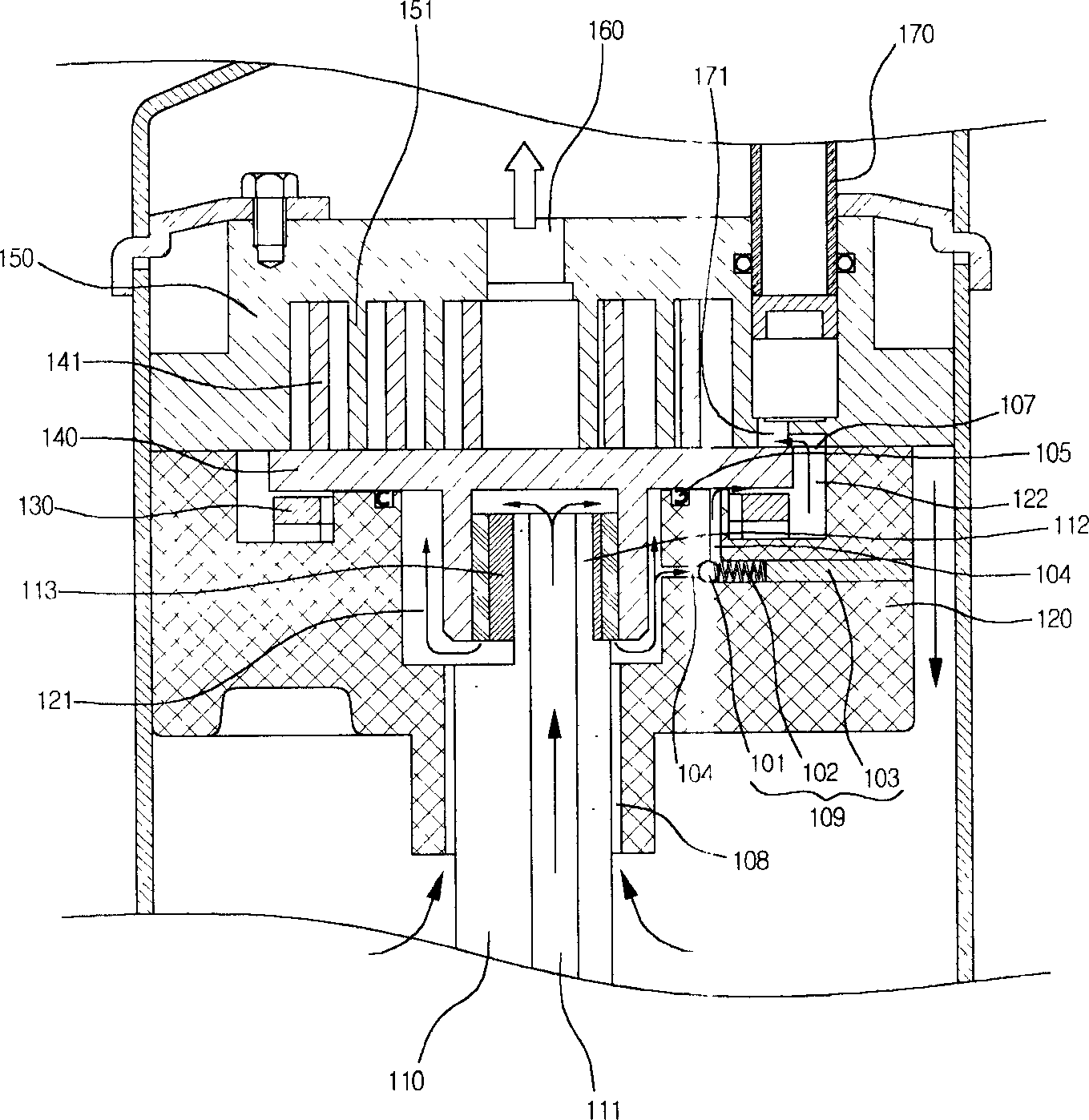

[0029] Such as image 3 and Figure 4 As shown, the scroll compressor of the negative pressure adjustment structure of the present invention is formed by a lubricating oil passage 111 penetrating the inside of the drive shaft 110 in the axial direction; 112 ; the sliding sleeve 113 formed on the outside of the eccentric portion 112 ; formed on the upper side of the drive shaft 110 , the upper frame 120 supporting the drive shaft 110 and other components are formed.

[0030] A main bearing 108 is formed at a portion where the inner peripheral surface of the upper frame 120 contacts the outer peripheral surface of the drive shaft 110 . The central portion of the upper frame 120 is formed along the inner peripheral surface of the upper frame 120 to accommodate the lubricating oil rising through the lubricating oil passage 111 and a small amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com