Receiver with multiple drive coils

A technology for exciting coils and receivers, which is applied to the adaptation of hearing impaired stereo signal reproduction, sensors, electrical components, etc., to achieve the effect of suitable response and high maximum output capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The moving plate receiver described below is particularly suitable for hearing aid miniature receivers. However, this principle can also be applied to other miniature portable devices, eg headphones.

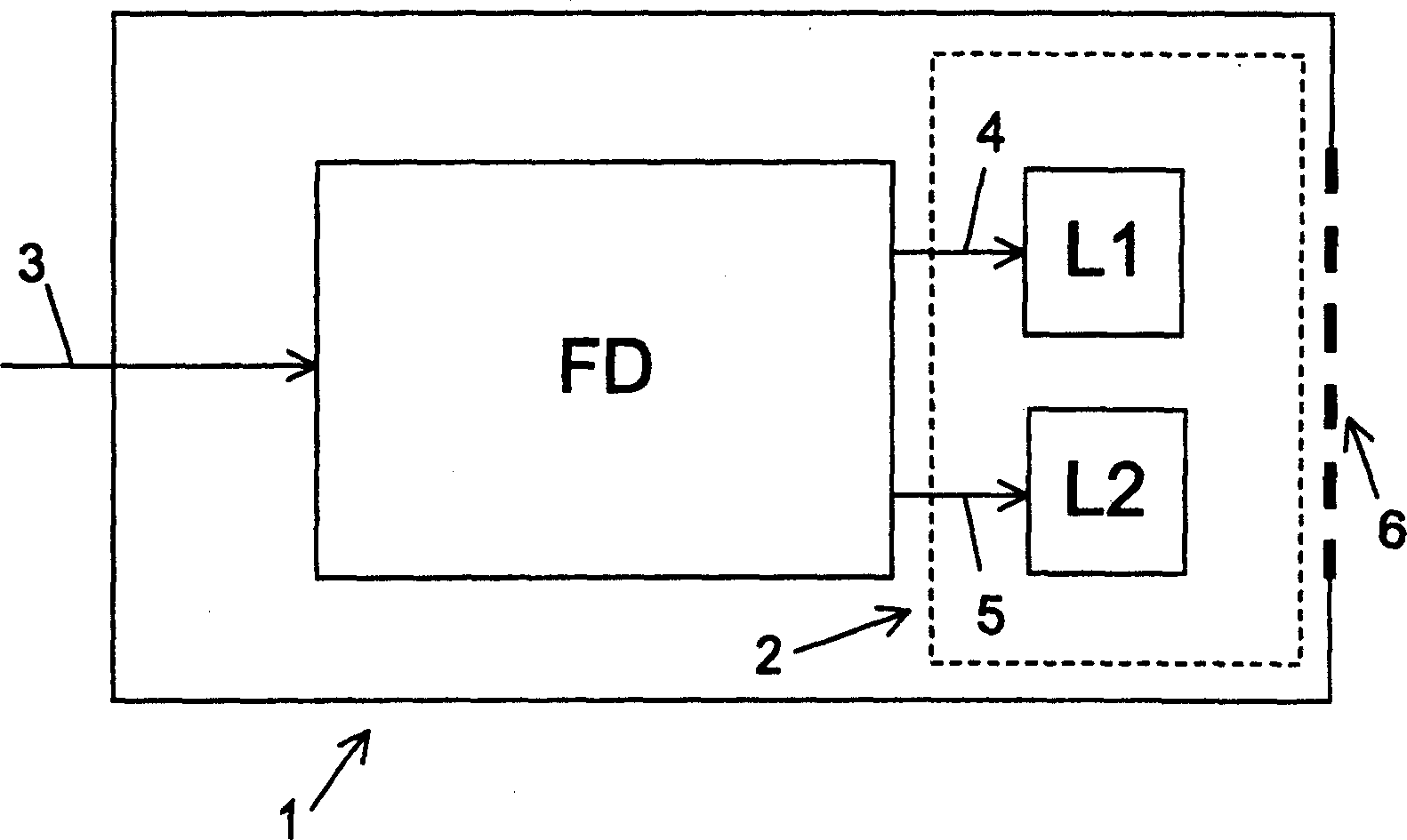

[0046] figure 1 A schematic diagram is shown which illustrates the basic principle of the moving plate receiver 1 according to the invention. The receiver 1 comprises a moving plate transducer 2 with two excitation coils L1 and L2. The receiver 1 is adapted to receive an audio input signal 3 and convert it via a sound emitting aperture 6 into a corresponding sound output signal. The audio input signal 3 may be provided as an analogue or digitally modulated signal, eg a PWM or PDM signal, wherein the audio signal is modulated by an ultrasound carrier. For example, the audio input signal 3 may be a differential output signal from a class D amplifier.

[0047] With the frequency divider FD the audio signal 3 is split into a first audio signal 4 of a first frequency range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com