Sewing machine and method for regulating drive force of its needle

A technology for sewing machines and machine needles, applied in the direction of sewing machine needle holders, sewing machine components, sewing equipment, etc., which can solve problems such as unusable, insufficient length margin, and difficult belt disassembly, so as to improve workability and suppress manufacturing costs , The effect of shortening the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] (Overall configuration of the embodiment of the invention)

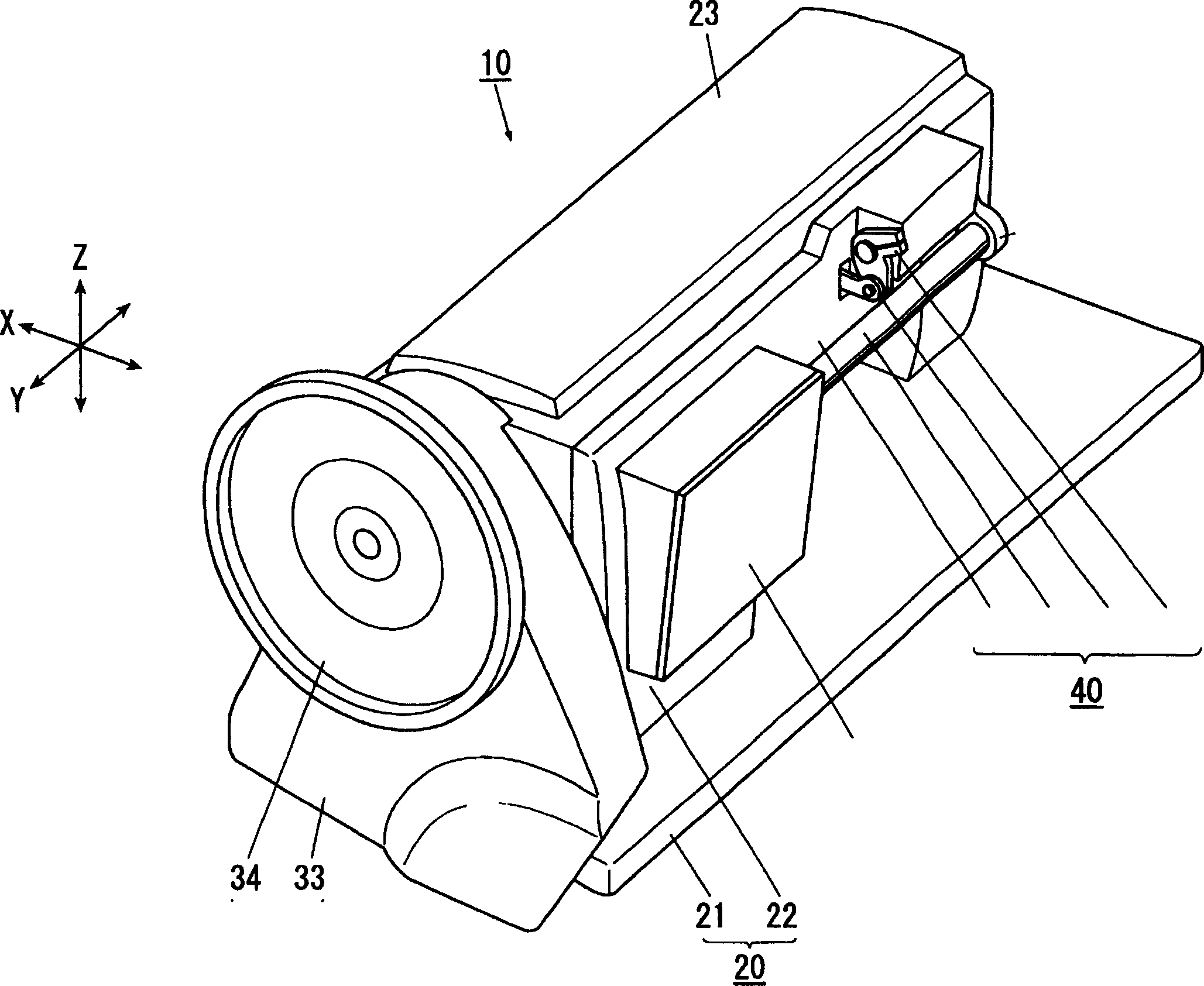

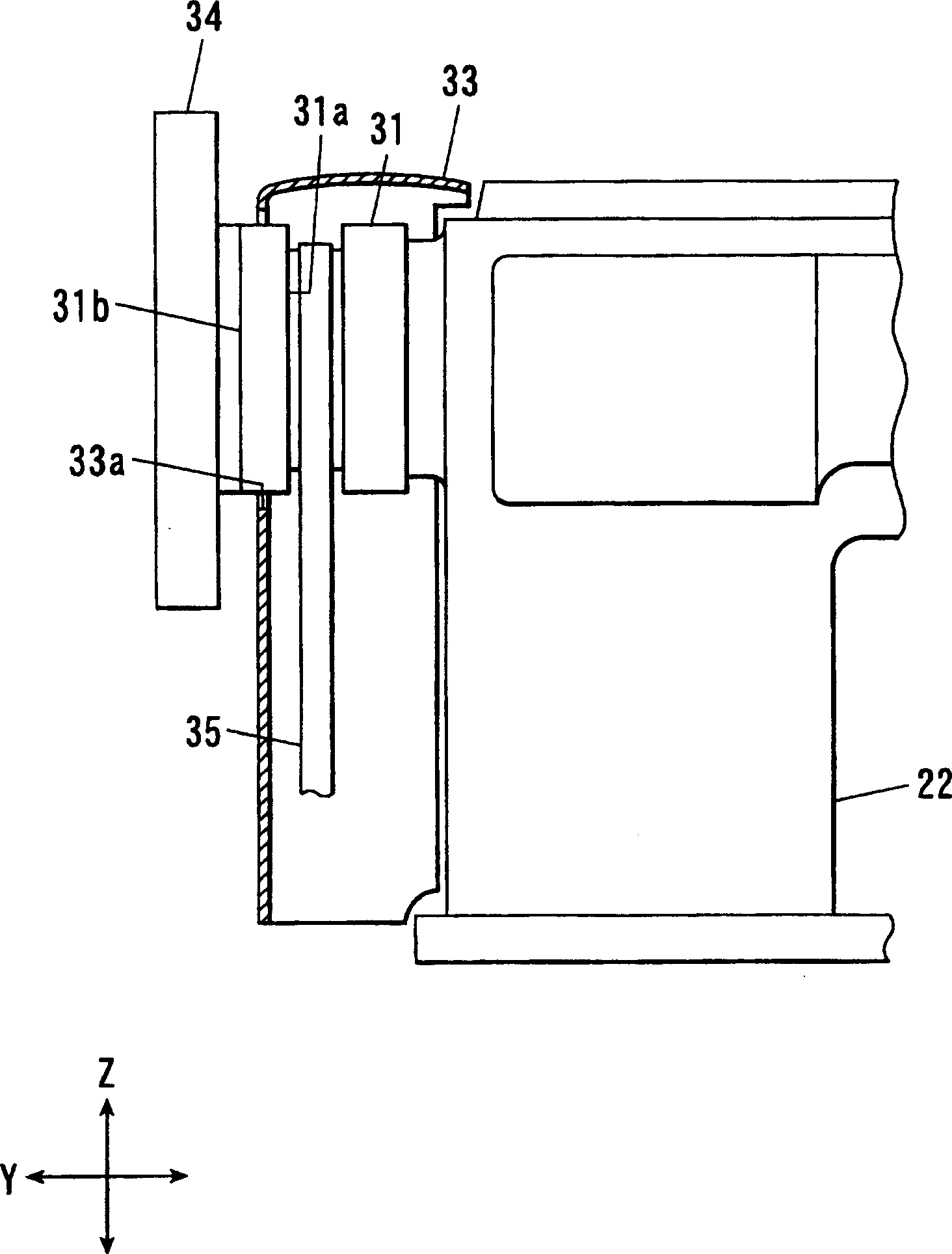

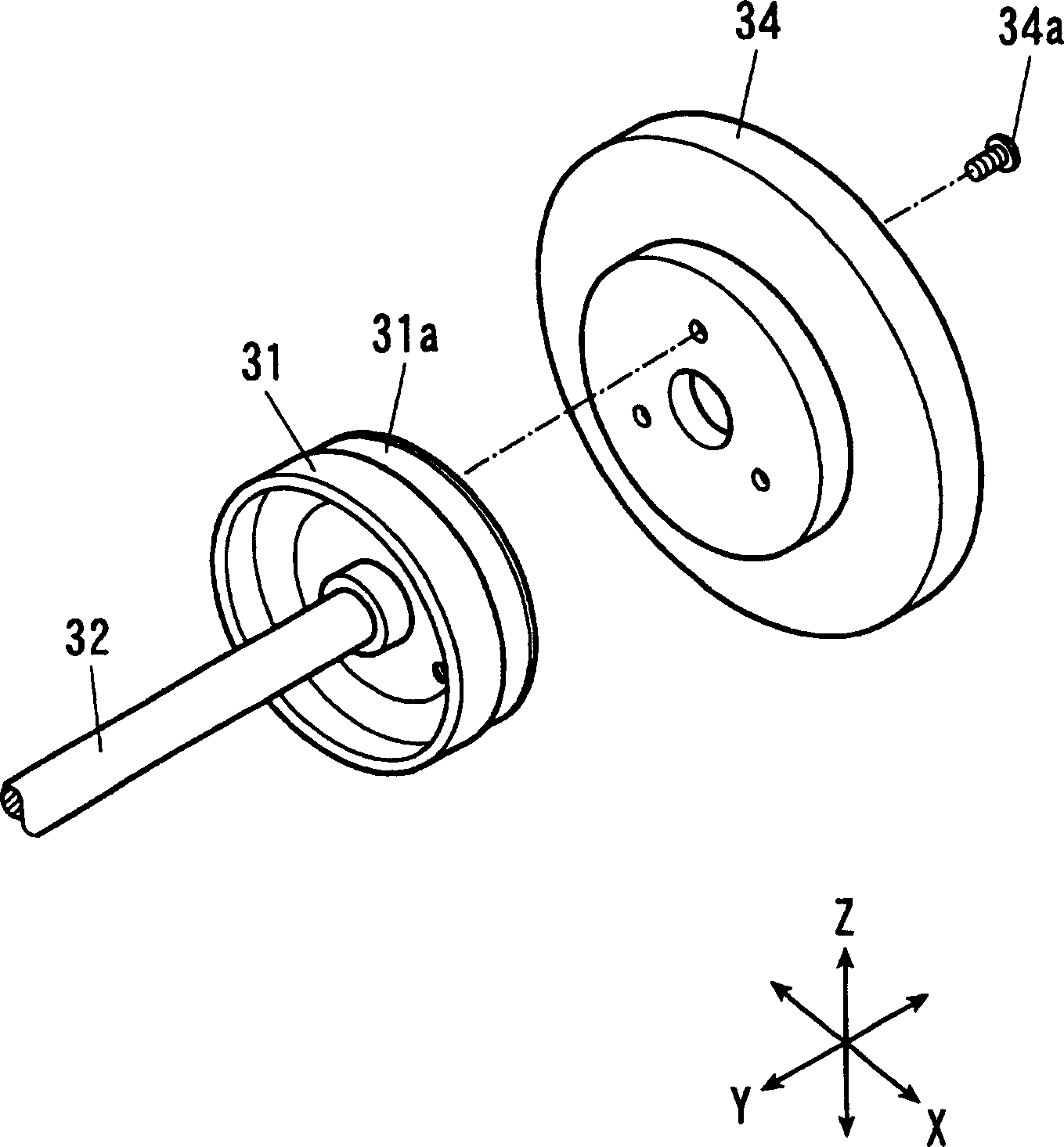

[0026] Below, refer to the attached Figure 1~3 , to describe the embodiments of the present invention in detail.

[0027] The above-mentioned lockstitch sewing machine 10 has a needle bar up and down mechanism (not shown) that moves the needle up and down, and a bottom mechanism that feeds the cloth as the sewing object placed on the needle plate 12 from below to a predetermined cloth feeding direction. The cloth feeding device (illustration omitted), and the sewing machine frame 20 that accommodates the needle bar up and down mechanism and the lower cloth feeding device, and the sewing machine frame 20 that can be loaded and unloaded on the sewing machine frame 20 and sends the cloth on the needle plate 12 from above to the prescribed cloth feeding direction. Cloth feeding device 40.

[0028] In the following description, the vertical up and down direction is taken as the Z-axis direction, and the longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com