Equipment for processing lens

A processing device and lens technology, which is applied in the direction of lenses, grinding drive devices, metal processing equipment, etc., can solve the problems of waste of preparation time, increased manufacturing costs, and decreased operating efficiency of processing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

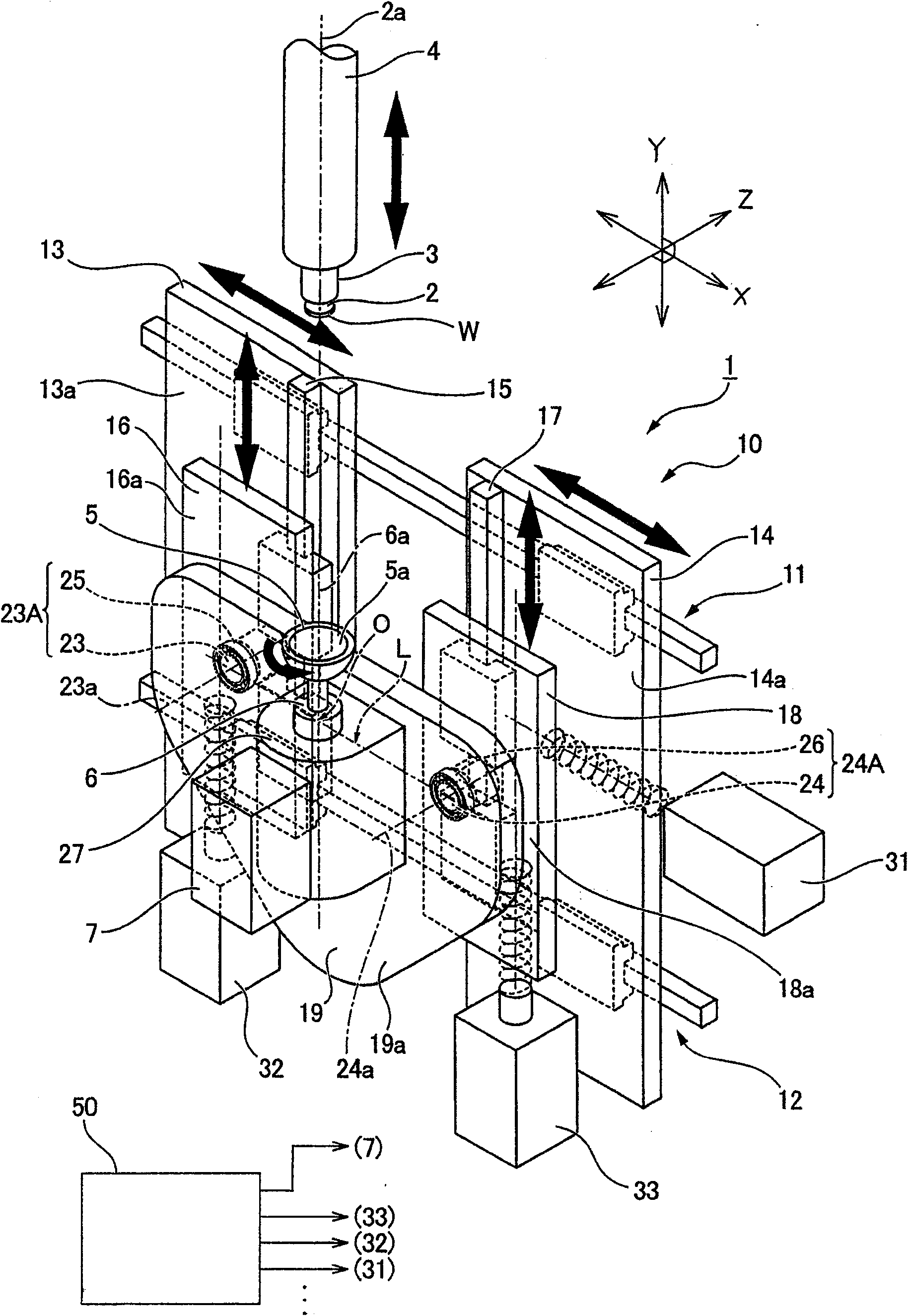

[0083] In the above-described embodiment, one X-axis motor 31 and two Y-axis motors 32 and 33 for independently moving the first and second Y-axis plates 16 and 18 are provided. Conversely, two X-axis motors for independently moving the first and second X-axis plates 13 and 14 and one Y-axis motor for moving one of the first and second Y-axis plates 16 and 18 may be arranged.

[0084] In the above-described embodiments, the present invention is applied to a lens spherical surface processing device. The present invention is also applicable to lens processing devices for processing curved surfaces other than spherical surfaces. For example, the conical surface processing of the lens material W can be performed by moving the processing tool along the conical surface. In addition, it is also possible to perform aspherical processing in the same way as the waveform generator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com