Method for cleaning separation membrane

A washing method and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of decreased activated sludge activity, low device operation efficiency, long stop filtration time, etc. The effect of shortening, suppressing drug costs, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

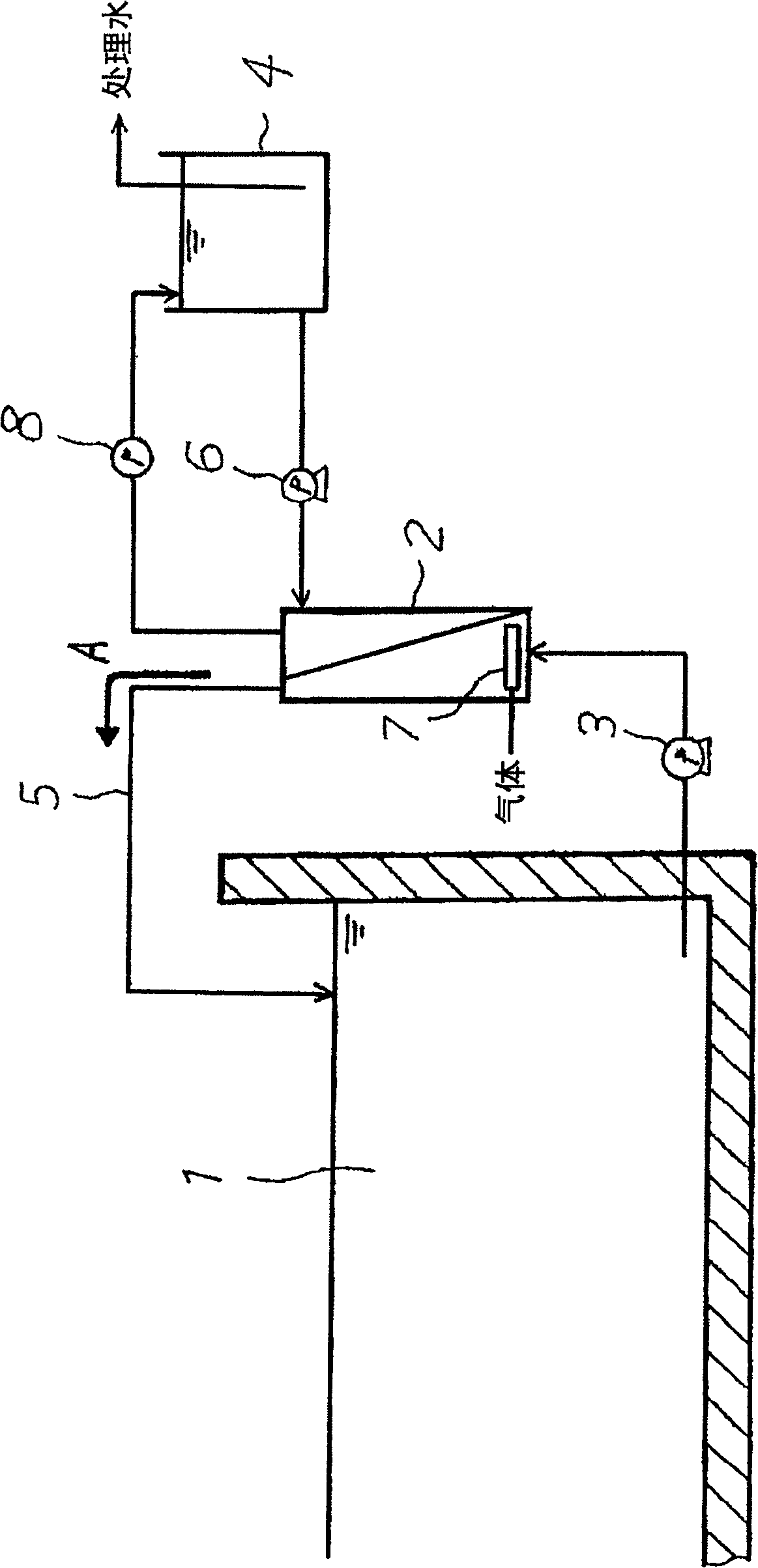

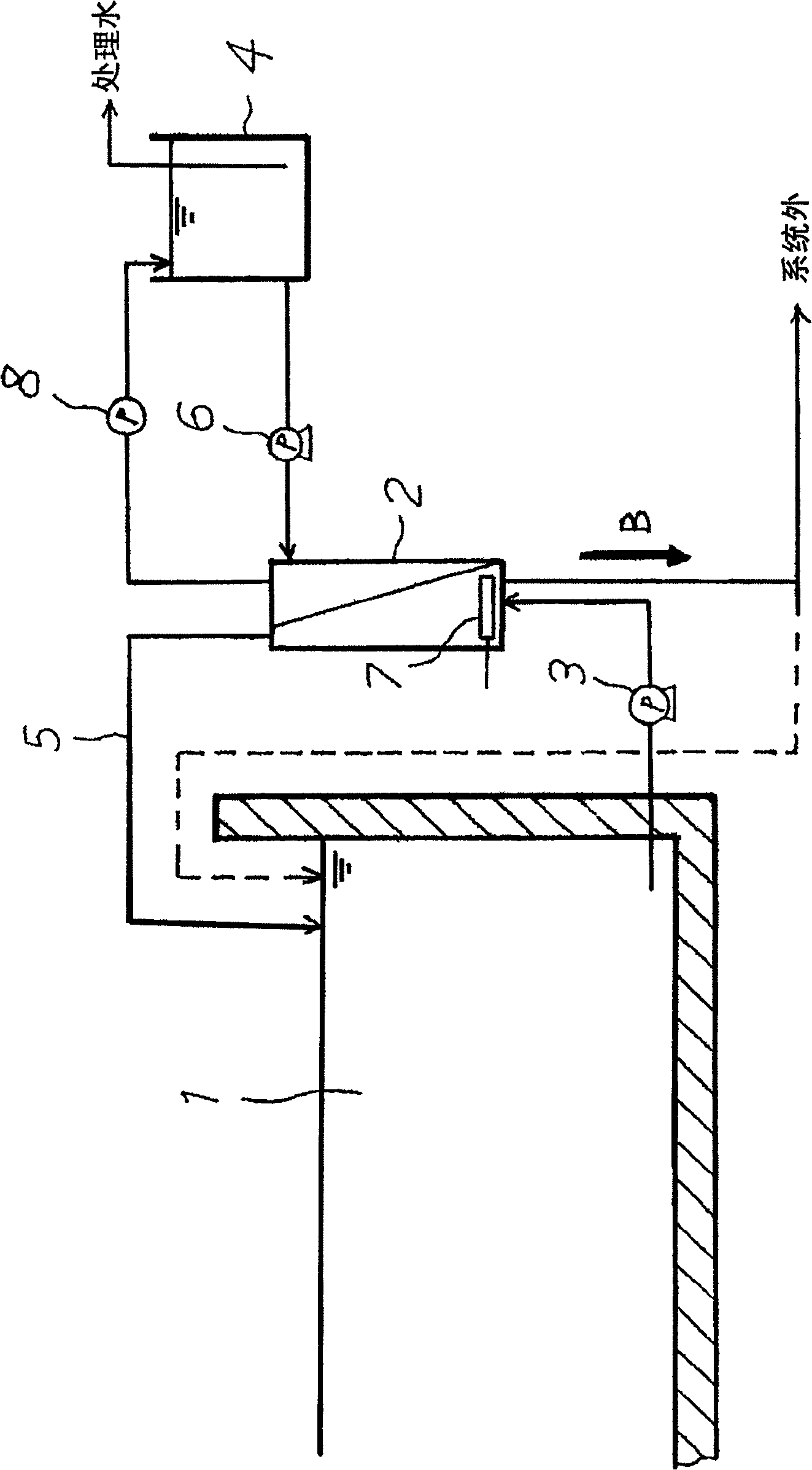

[0028] Such as figure 1As shown, the water in the activated sludge treatment tank of sewage is led out and circulated to the outside, and cross-flow filtration is performed through an internal pressure ceramic membrane. The separation membrane used is a monolithic membrane (membrane micropore diameter 0.1 μm, membrane pore diameter 4 mm) manufactured by the applicant company. As a result of operating under the conditions of circulating water volume of 1.0m / s and membrane filtration flow rate of 2.4m / d, the membrane permeation pressure rises rapidly, and stable operation cannot be performed even if original backwashing is performed every 45 minutes. In addition, 0.11m / s air was supplied from the gas supply device to make the raw water side of the membrane a gas-liquid mixed phase flow, but it still could not operate stably. In contrast, under the conditions of circulating water volume of 1.0m / s, membrane filtration flow rate of 2.4m / d, and gas flow rate of 0.11m / s, pulse backw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com