Rubber spring vibration-dampening chair

A rubber spring and seat technology, which is applied to seat suspension devices, vertically adjustable seat chairs, chairs, etc., can solve the problems of ordinary springs with small damping coefficient, poor vibration reduction effect, and poor ride comfort, etc., and achieve improvement Passenger comfort, innovative device structure, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

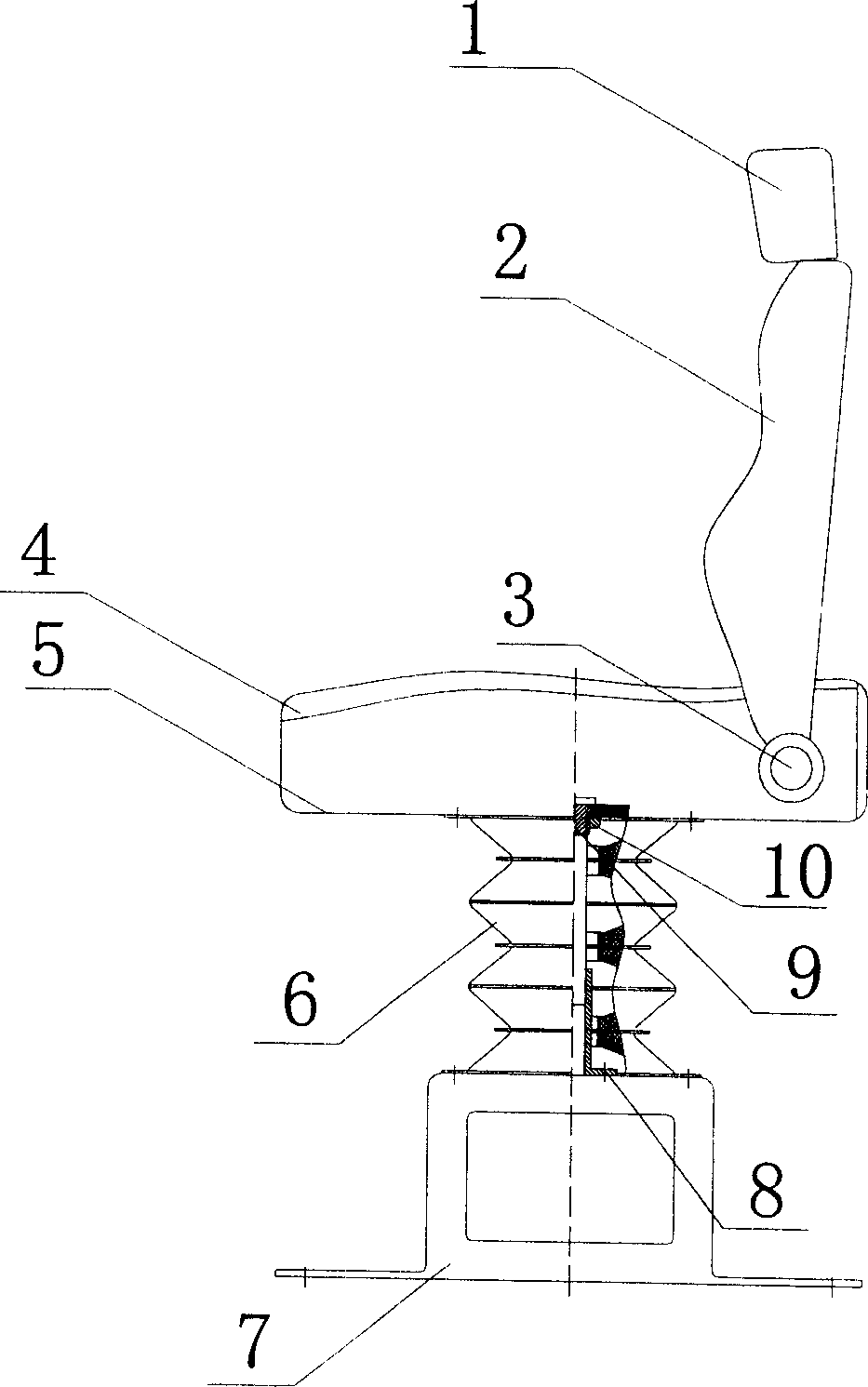

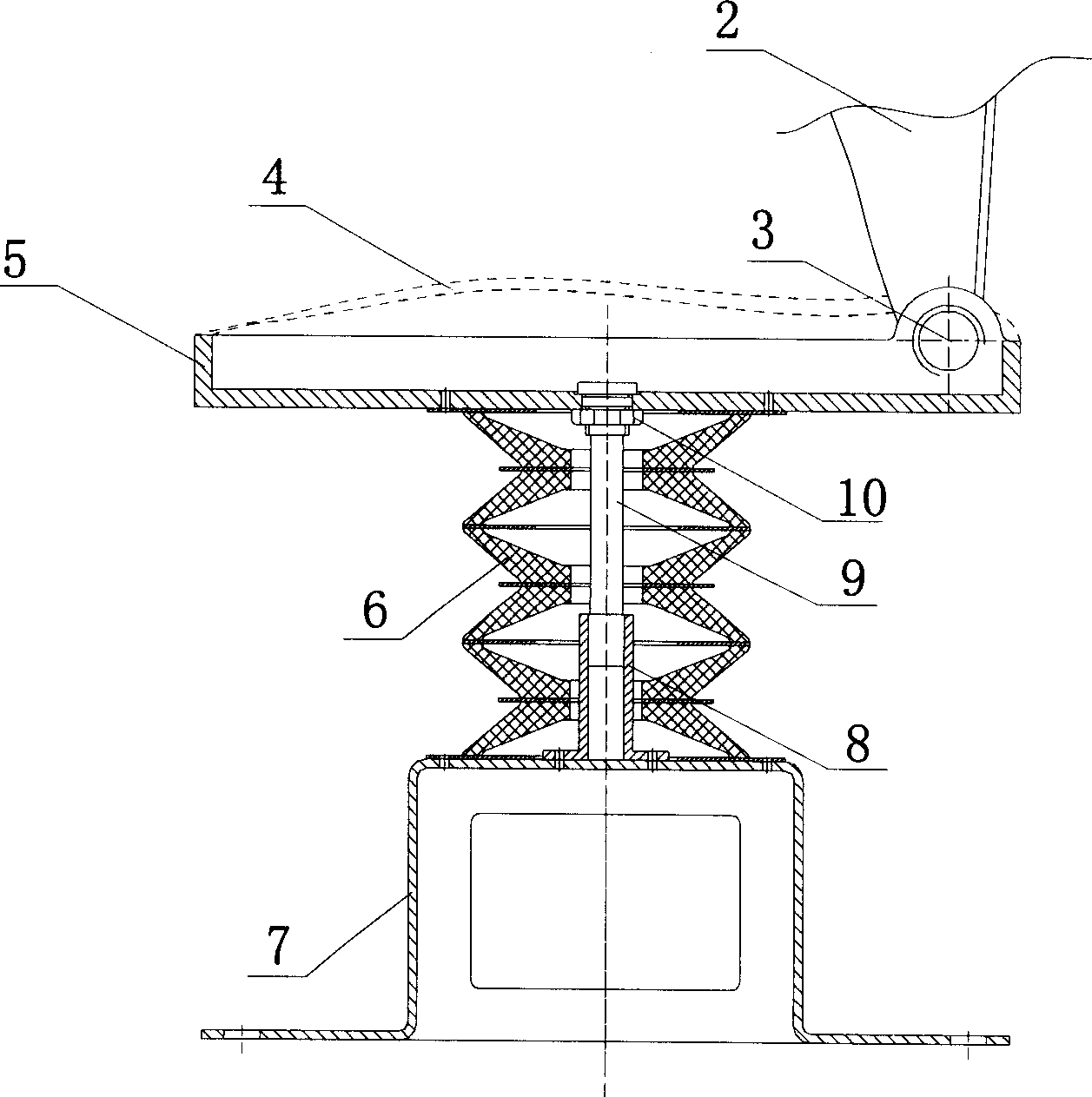

[0014] The rubber spring damping seat of the present invention is composed of a damping assembly, a support assembly and a guide assembly. The damping assembly of the device includes a headrest 1, an adjustment knob 3, a seat cushion 4, a rubber spring 6 and the like. The headrest 1 is connected with the backrest 2 through bolts, and the backrest 2 is connected to the upper connection base plate 5 through the adjustment knob 3. The angle of the backrest can be adjusted with the knob 3. The seat cushion 4 is connected to the upper connection base plate 5 through bolts, and the seat cushion 4 Soft pads with damping effects should be selected, and hard seat pads are not allowed. The upper end plate of the rubber spring 6 is connected to the upper connecting bottom plate 5 with bolts. The kinetic energy of the coming vibration achieves the effect of vibration reduction.

[0015] The support assembly mainly includes an upper connection base plate 5 and a lower connection base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com