CMM arm with exoskeleton

A technology of equipment and components, applied in the field of CMM arms, can solve the problems of the system stopping function, unusable, and reducing the accuracy of photogrammetry system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

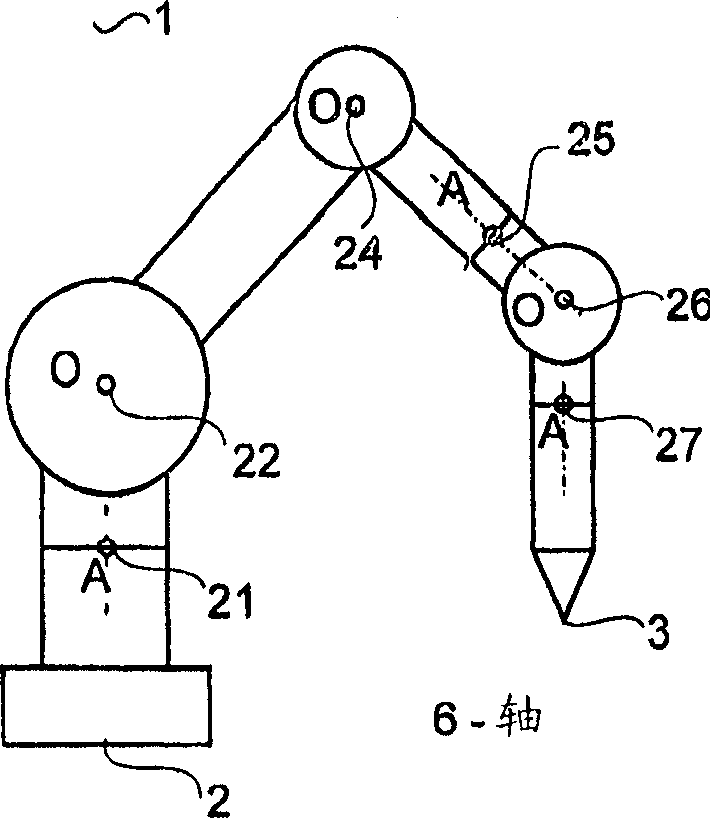

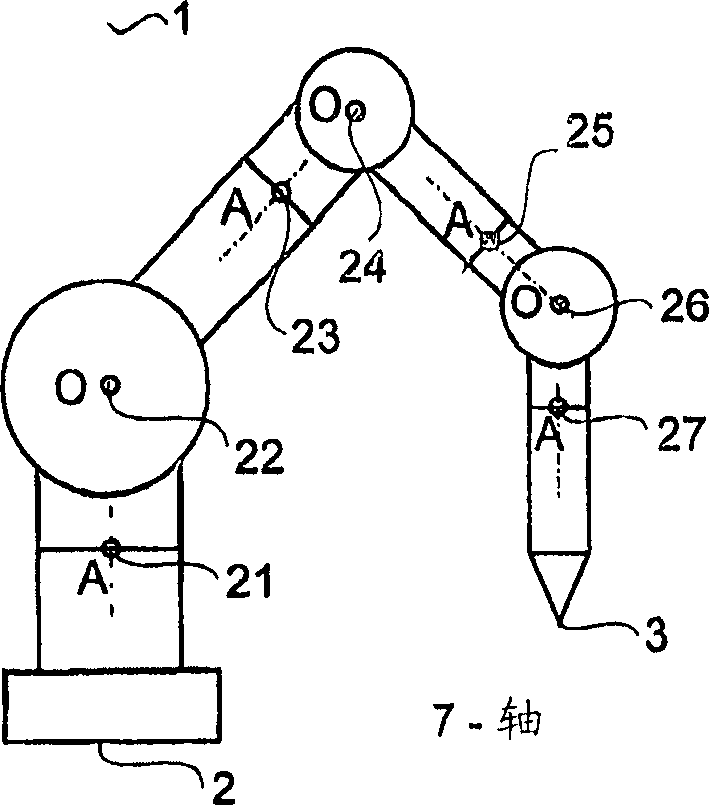

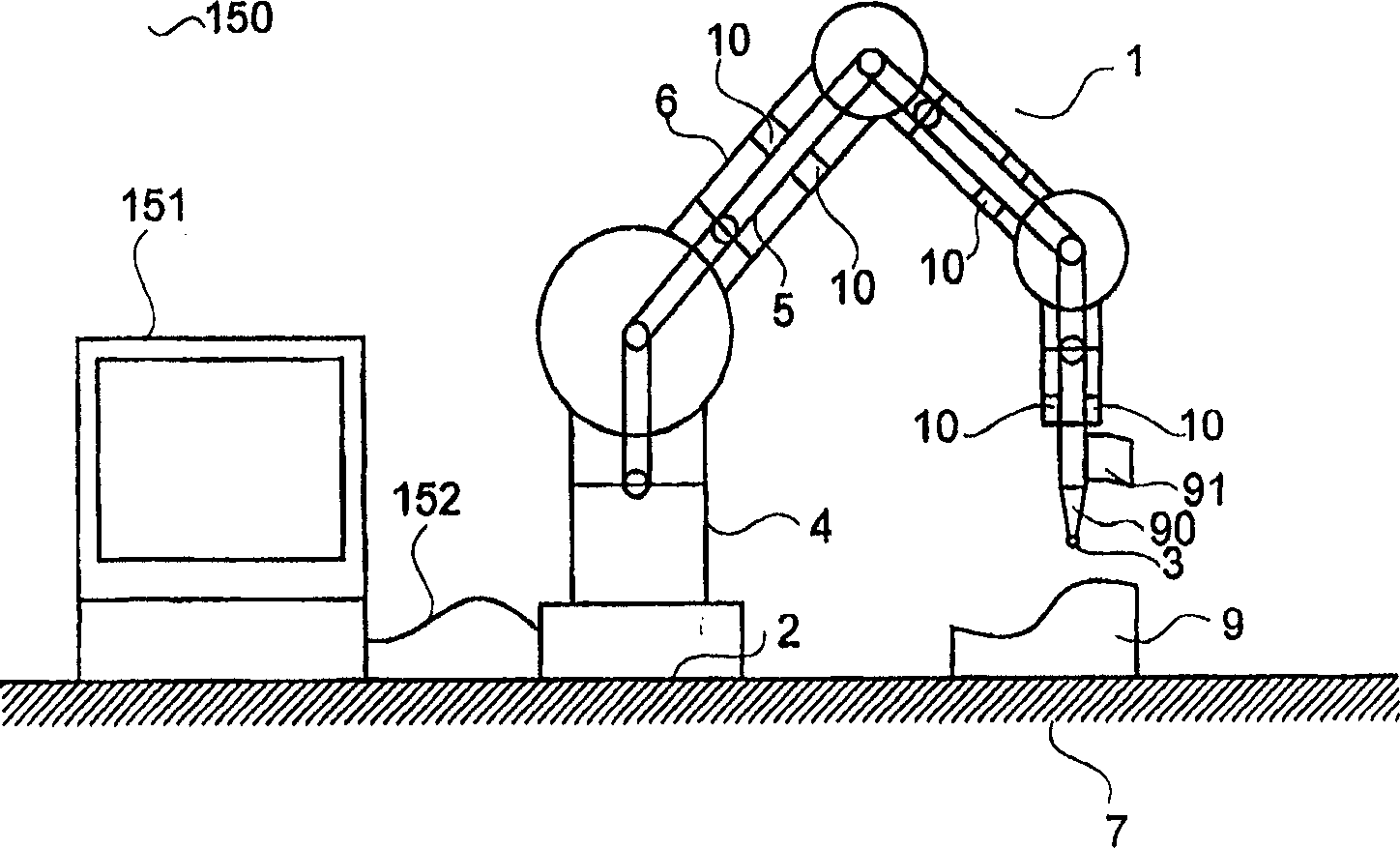

[0196] Portable Robot CMM Arm

[0197] A first embodiment of such an Internal CMM Arm with Exoskeleton is a Portable Robotic CMM Arm. This Portable Robot CMM Arm embodiment includes an Internal CMM Arm guided by an Exoskeleton. The Exoskeleton supports and steers the Internal CMM Arm through actuators so that it can be accurately measured. The present invention can follow many robot CMM arm articulated arm layouts picture Implementation. There are two preferred layouts for the Robot CMM Arm according to the first embodiment of the invention picture : 6-axis with 6 joints and 7-axis layout with 7 joints picture .

[0198] Robot CMM Arm Joint and Segment Layout picture

[0199] Figure 1A and 1B respectively show preferred 6-axis and 7-axis layouts of the Robot CMM Arm 1 according to the first embodiment of the invention picture of picture Show. An Articulated Robot CMM Arm 1 has a base end 2 and a probe end 3 and includes a set of segments and swivel joints between t...

no. 2 example

[0586] Industrial Robot CMM Arm

[0587] In this second embodiment, the disclosed Industrial Robot CMM Arm is used to provide accurate robot motion. In this second embodiment, a seven-axis industrial robot CMM arm with a common base section and a common probe section 8 is provided. The common probe section can carry heavy probes or tools and is subject to significant forces while providing precise position information. The industrial robot CMM arm is not only more reproducible than existing industrial robots, but also about 10 times more accurate. see now Figure 53, the industrial robot CMM arm 450 has a common base 4 , and the common base 4 includes the CMM segment 31 , the transmission device 1 71 and the robot exoskeleton segment 1 41 . Industrial Robot CMM Arm 450 also has Common Probe Section 8 451 , which includes CMM Section 8 38 , Transmission 8 78 and Exoskeleton Section 8 48 . In effect, it provides a rigid transmission 8 78 . The CMM segment 2-7 32-37 of the C...

no. 3 example

[0654] In this third embodiment, a movably supported Robot CMM Arm is disclosed which significantly reduces the forces and moment.

[0655] Forces and moments acting on the Robot CMM Arm of the first embodiment

[0656] At some spatial layouts of the Robot CMM Arm 1 there are considerable loads acting on the Internal CMM Arm 5 such that the provided seven motors acting through the seven Exoskeleton Joints 1-761-67 of the Exoskeleton 6 The 176 setup does not provide enough control output to reduce these loads. In some spatial arrangements, all the weight of the following segments of the Internal CMM Arm 5 acts on the joints. For example, the total weight of the CMM Segment 2-8 32-38 falls directly on the CMM Joint 151 when the Internal CMM Arm 5 is in a vertical spatial layout. Similarly, the total weight of CMM Segments 3-8 33-38 falls directly on CMM Joint 2 52, and the same goes for CMM Joint 3 53 through CMM Joint 7 57 up to the arm. The seven drive trains in the exoske...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extend | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com