Device for fixing an internal magnetic screen to a frame

A magnetic screen and frame technology, applied in the field of color cathode ray tubes, can solve the problems of high material cost, inability to reuse parts, difficulty in automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

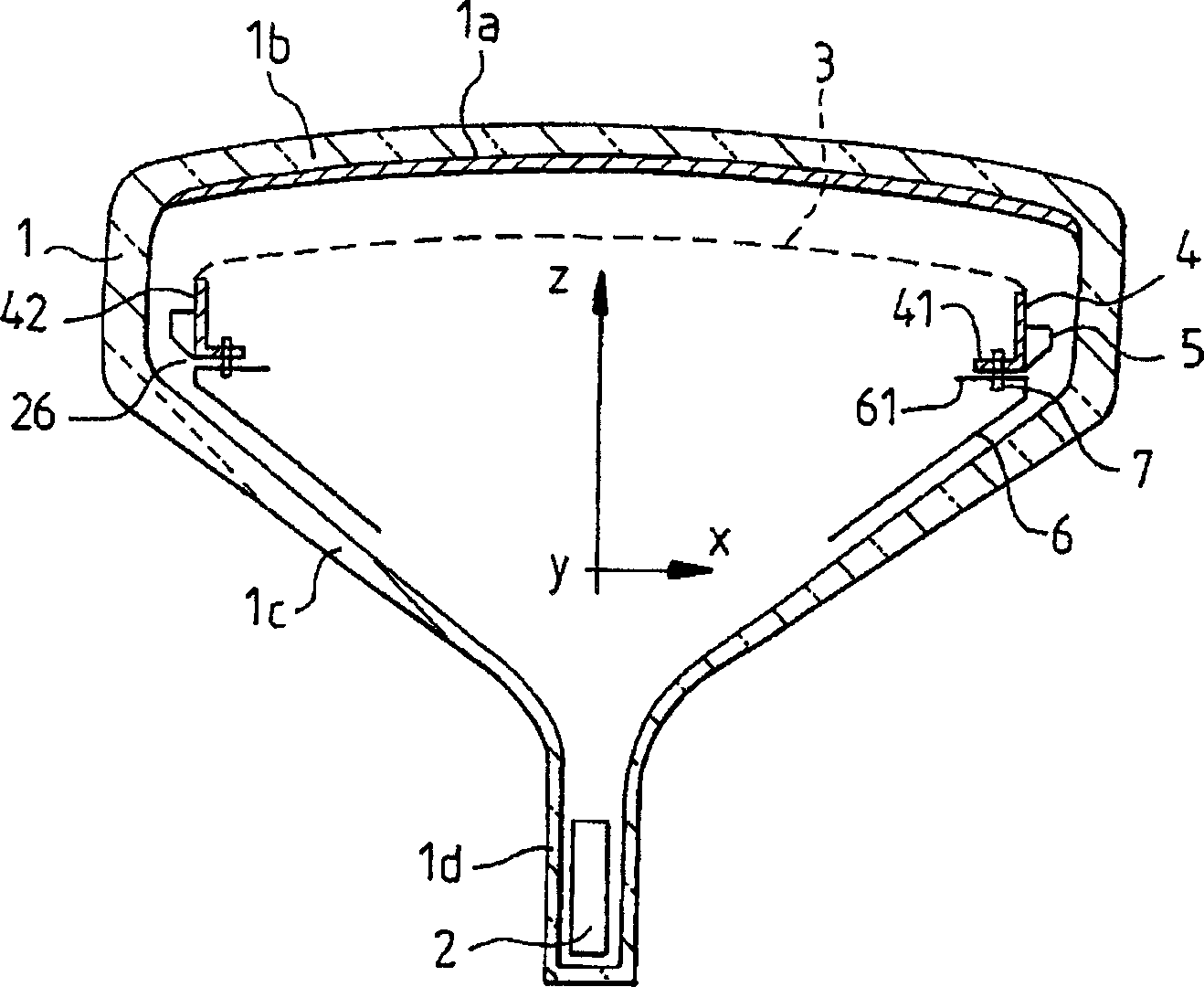

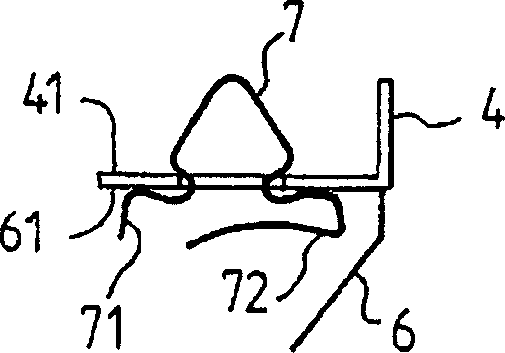

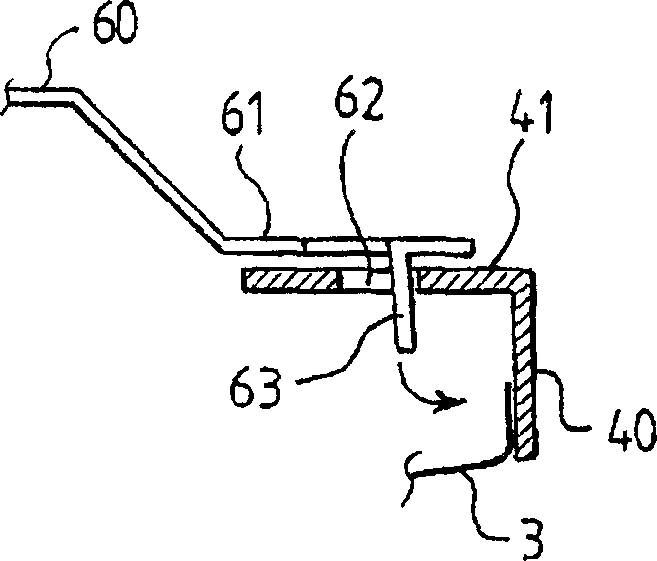

[0020] figure 1 The structure of a color cathode ray tube is shown in cross-section. This kinescope 1 comprises frame / shadow mask assembly, and described frame / shadow mask assembly comprises shadow mask 3, and the curved surface of described shadow mask can be realized by stamping steel plate or invart steel plate, and described surface is arranged at a distance from fluorescent screen 1a. At a certain distance, the phosphor screen is placed on the glass panel 1b of the picture tube; the shadow mask is held in place by a rigid frame 4, to which the shadow mask is connected by welding at its peripheral edge, the The peripheral edge is folded to extend within said frame in a direction substantially parallel to the longitudinal axis Z. The frame itself is rectangular in shape, each side of which has at least partially an L-shaped cross-section, the frame having a side 42 extending in a direction parallel to the longitudinal axis and a flange 41 substantially perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com