Hard disc driver disc taking and placing device

A technology of hard disk drive and pick-and-place device, which is applied to instruments, record carrier structural parts, data recording, etc., can solve the problems of low transmission accuracy, high manufacturing cost, complex structure, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

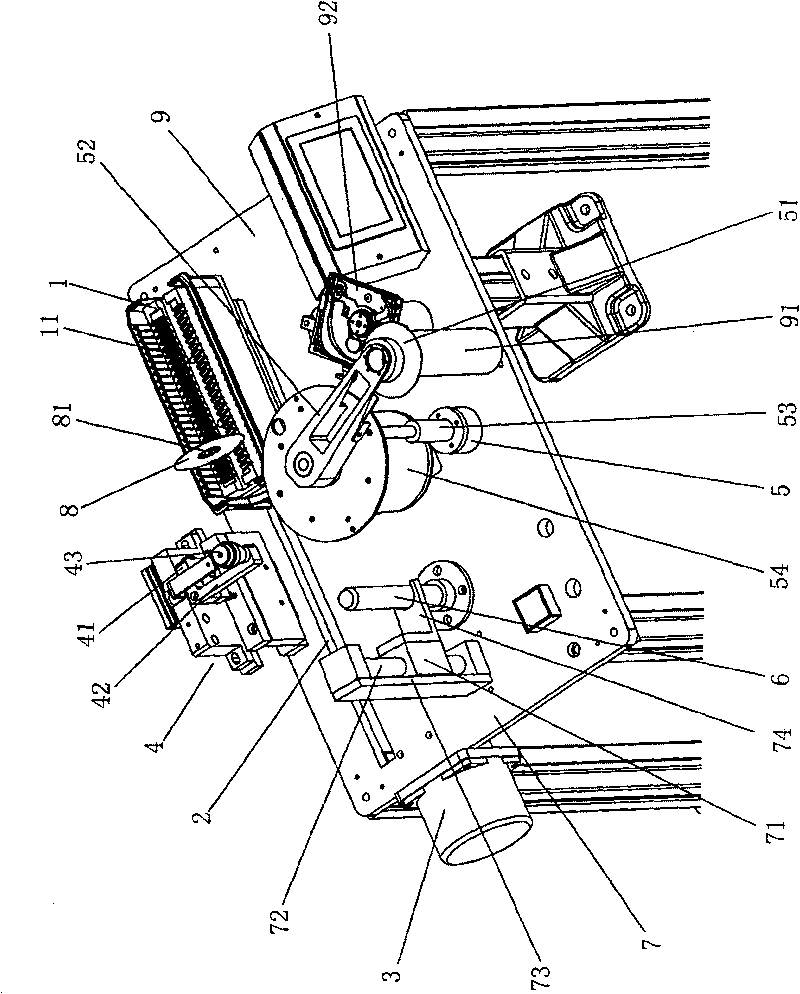

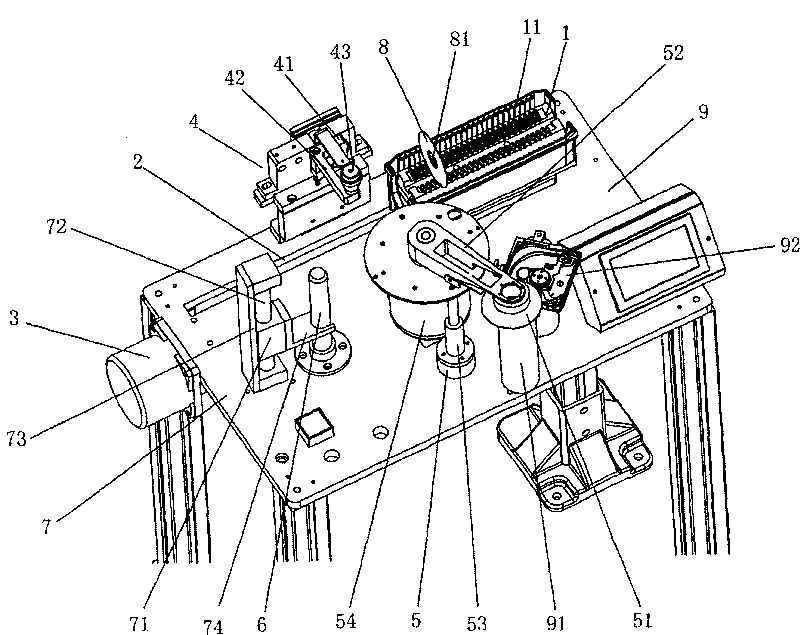

[0012] see figure 1 , The disk pick-and-place device of the hard disk drive of the present invention includes a disk holder 1, a guide rail 2, a disk holder driver 3, a turning assembly 4, a suction cup assembly 5, a spacer support 6 and a spacer driving assembly 7. The disk rack 1 is used to place the disk 8 to be taken and placed, and it is installed on the guide rail 2 . The output end of the disc rack driving member 3 is connected with the disc rack 1 to drive the disc rack 1 to move in translation in the horizontal plane. The overturning assembly 4 is used to overturn the vertically placed disk 8 on the disk holder 1 to a horizontal position for the suction cup assembly 5 to pick and place the disk 8 . The suction cup assembly 5 is used for sucking the disk 8 and placing the disk 8 on the designated position of the hard disk drive 92 . The spacer support 6 is used to place a plurality of stacked spacers to be taken and placed. The spacer drive assembly 7 is used to dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com