Cushioning and supporting device for conveyer belt

A technology of supporting device and conveyor belt, applied in the direction of conveyor, transportation and packaging, can solve the problems of easy deviation, short service life, easy damage of buffer rollers, etc. The effect of a small damping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

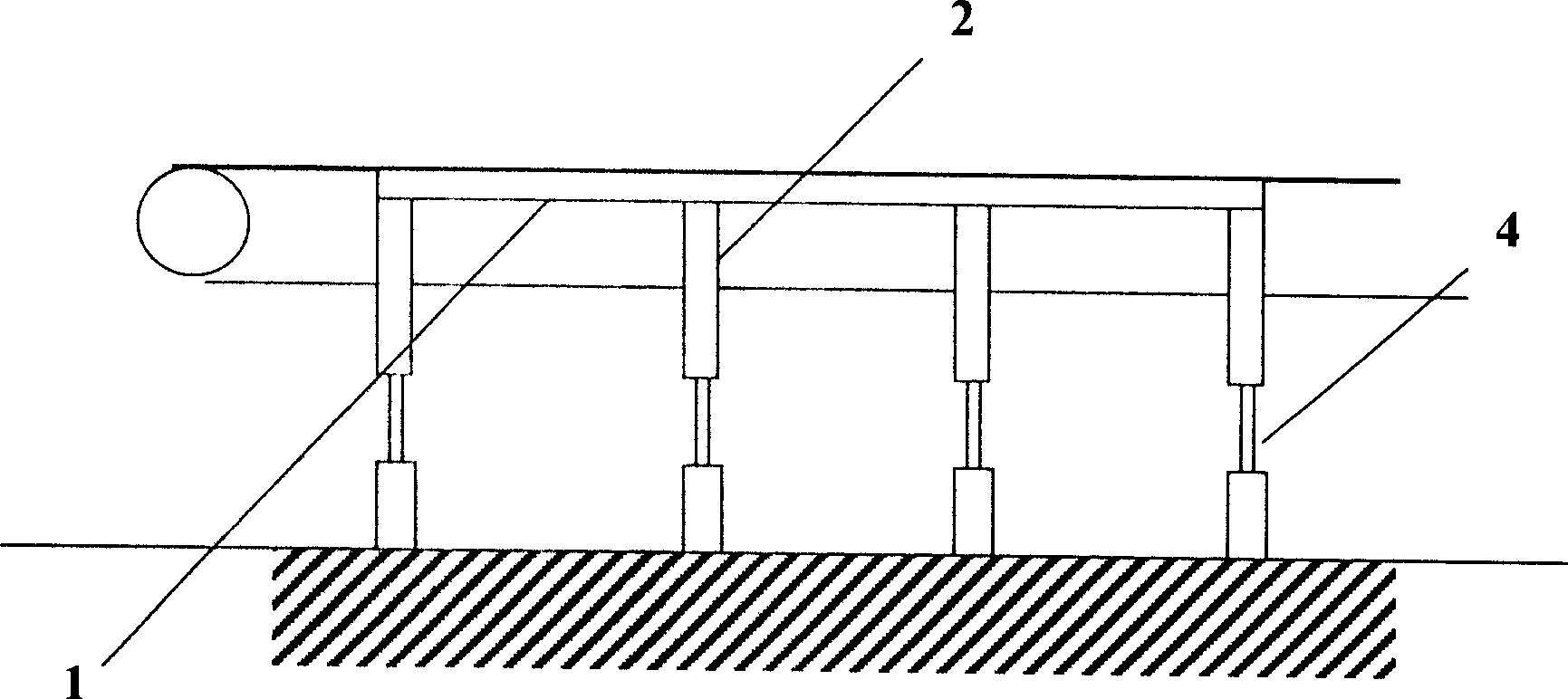

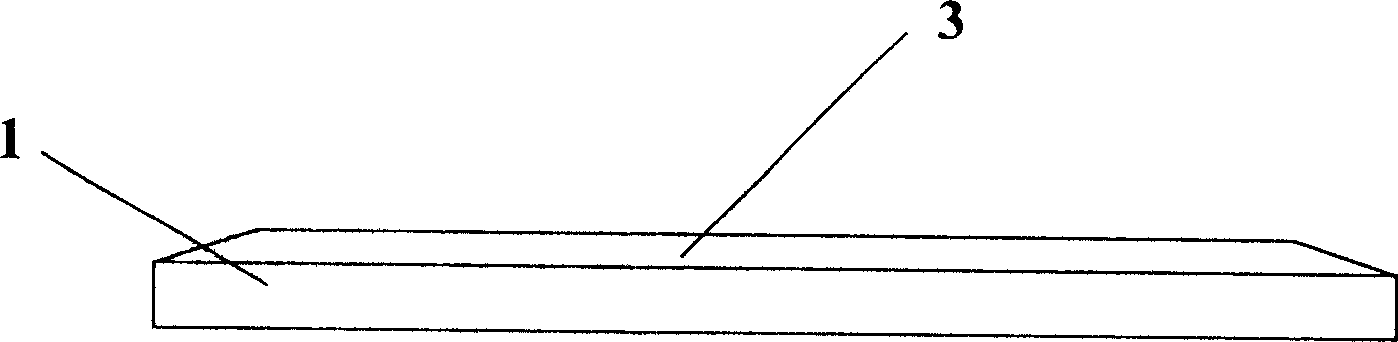

[0014] Such as figure 1 and figure 2 As shown, a buffer support device for a conveyor belt of the present invention is composed of a support plate 1 and a support foot 2, wherein the support plate 1 is arranged on the upper end of the support foot 2, and the support The upper side of the plate 1 is provided with a continuous supporting surface layer 3, and the continuous supporting surface layer 3 is formed by a plurality of ceramic sheets or fiberglass sheets, and any one of the ceramic sheets or fiberglass sheets is connected to the The above-mentioned support plate 1 is connected, and an elastic element 4 is arranged in any one of the above-mentioned support feet 2 .

[0015] In a preferred embodiment of the present invention, the elastic element 4 is composed of a hydraulic shock absorber.

[0016] The upper sides of both ends of the continuous supporting surface layer 3 are sloped, which can prevent the end faces of the continuous supporting surface layer 2 from cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com