Oil storage device

An oil storage device, oil bag technology, applied in the direction of transmission device, bearing, bearing of linear motion, etc., can solve the problem of uneven and continuous oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

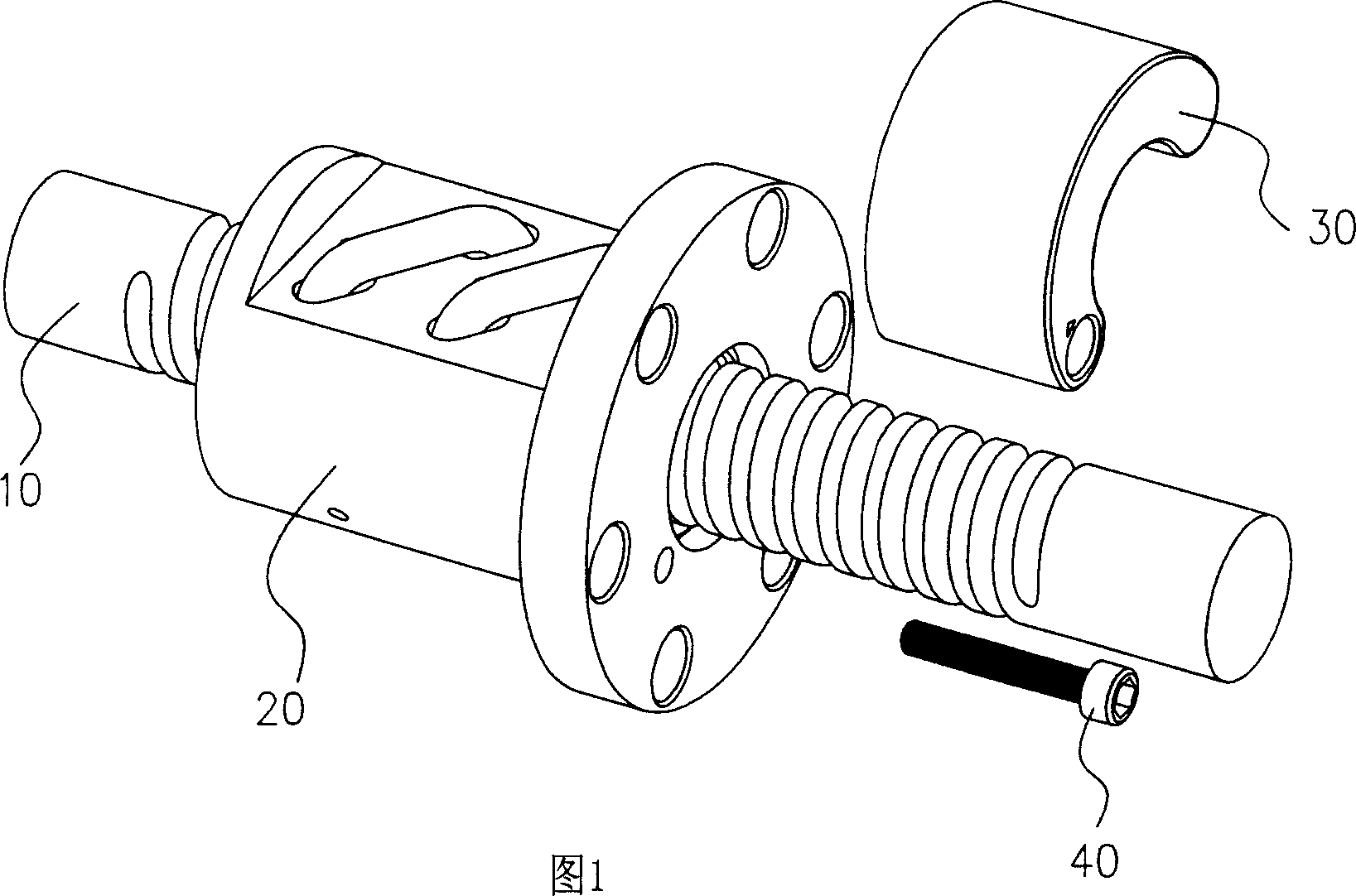

[0040] 1 is a schematic diagram of the application of the oil storage device of the present invention to a ball screw; the ball screw is mainly composed of a screw shaft 10 fitted with a nut 20, and the rolling body in the nut 20 is used to roll Therein, the screw shaft 10 and the nut 20 can move relative to each other. In this embodiment, the oil storage device 30 is disposed on the end surface of the nut 20 ; the oil storage device 30 is fixed on the nut 20 by the oil passage bolt 40 .

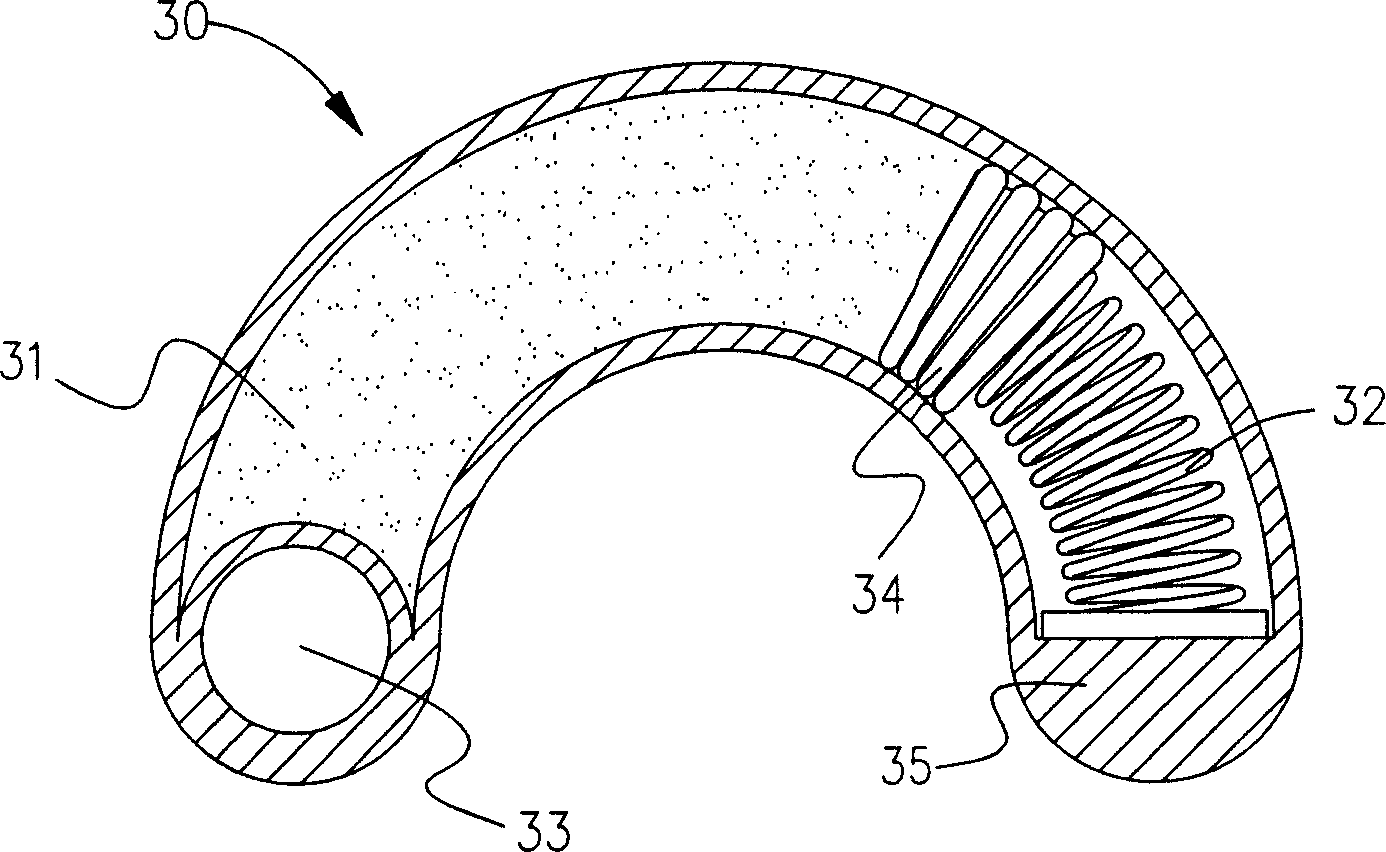

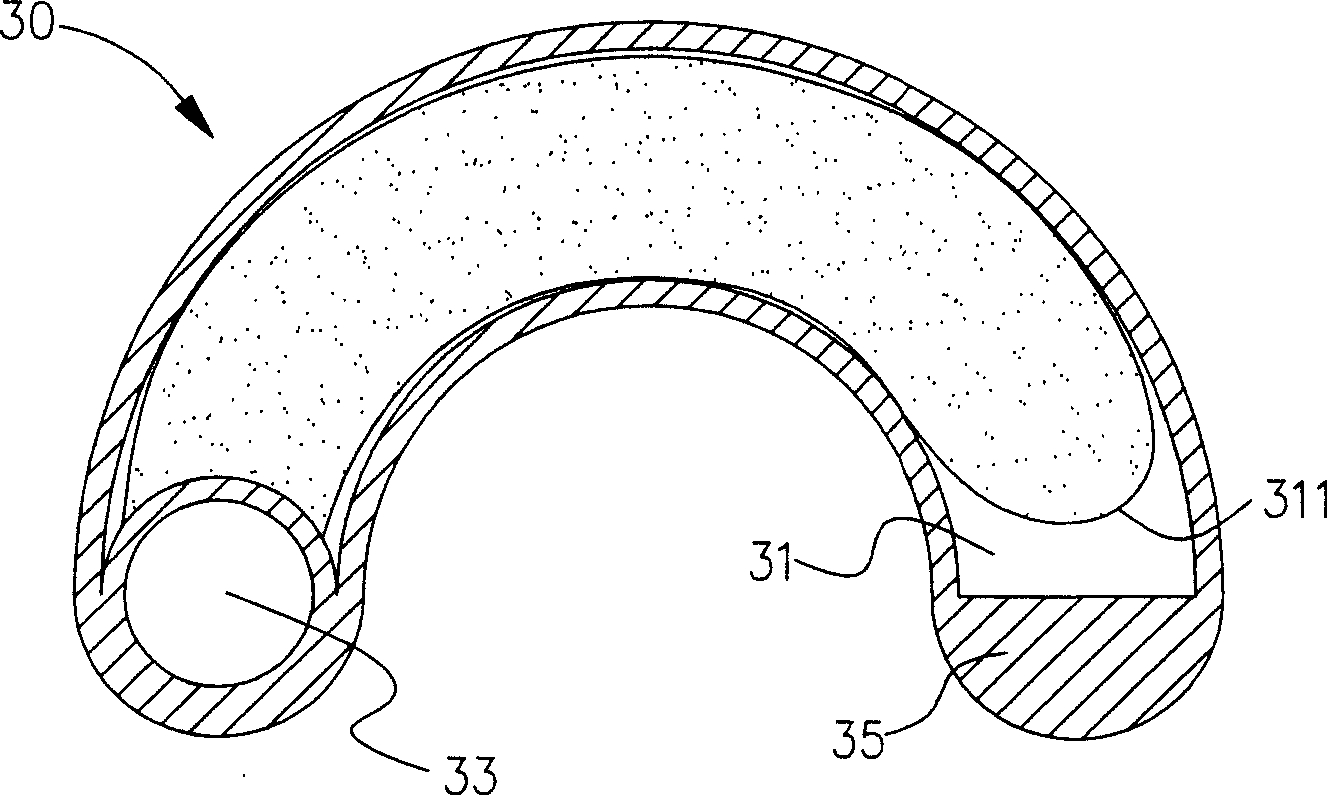

[0041] figure 2 It is a schematic cross-sectional view of the first embodiment of the oil storage device in FIG. 1; wherein the oil storage body 35 of the oil storage device 30 has an oil storage space 31 inside to store lubricating oil; and the oil storage body 35 is also provided with an oil through hole 33, The lubricating oil in the oil storage space 31 can be output outward; the elastic body in the oil storage space 31 of the oil storage device 30 in this embodiment is a structure in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com