Link operating device

A technology of linkage device and braking mechanism, applied in mechanical control device, device to prevent/restrict/recover the movement of parts of control mechanism, manual control mechanism, etc., can solve the problem of low rigidity and increase the size of parallel linkage mechanism , the operation device is cumbersome, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

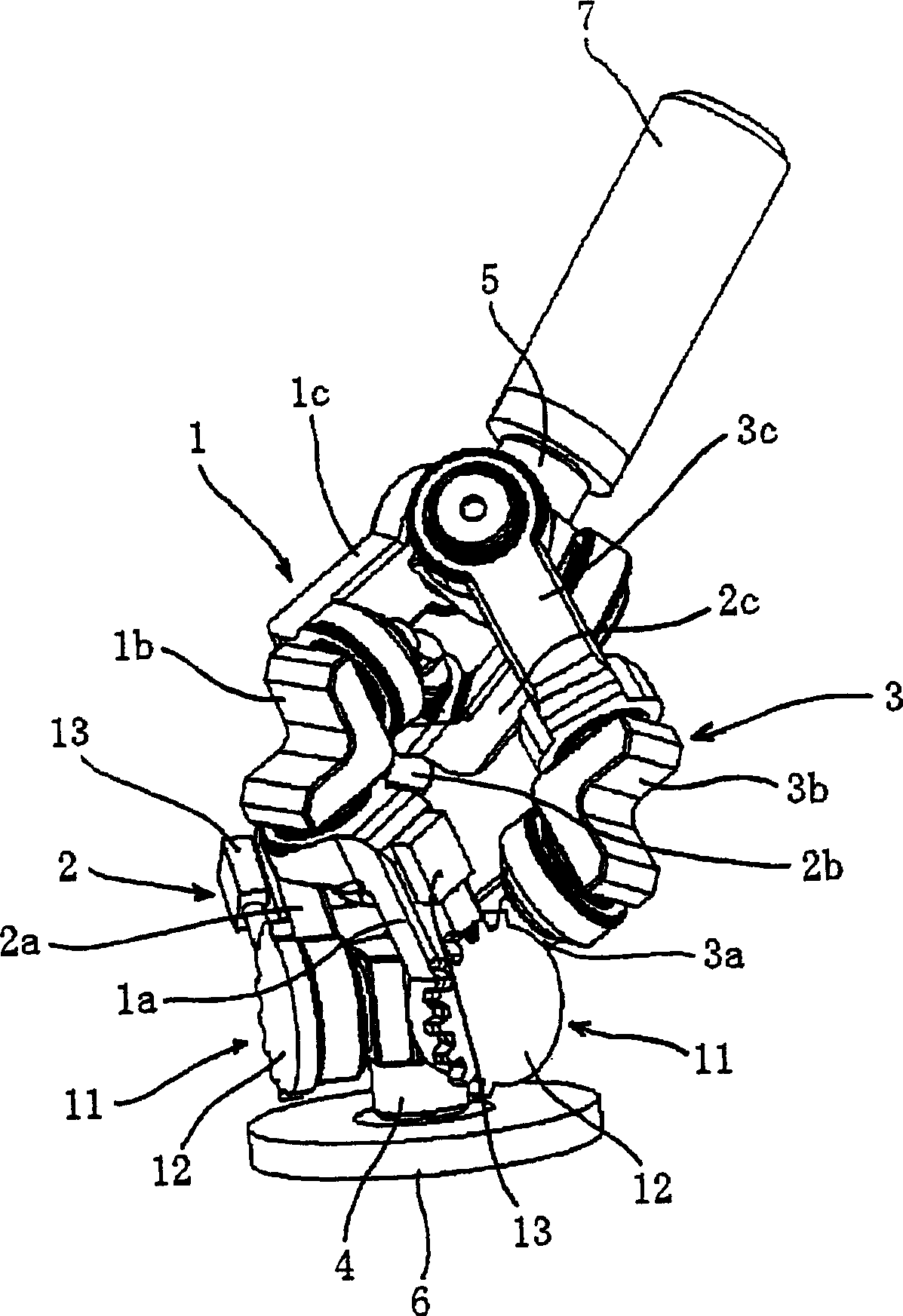

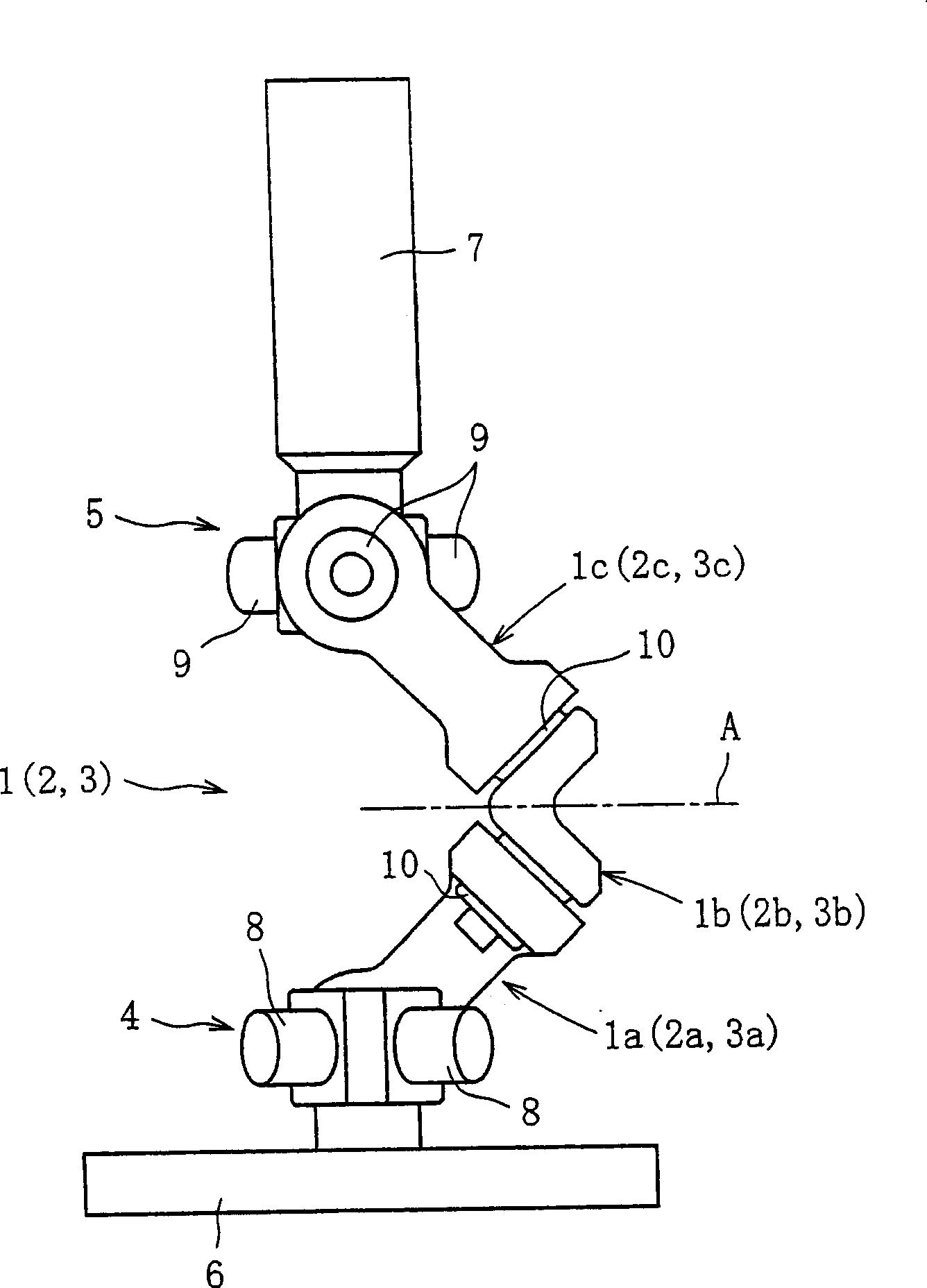

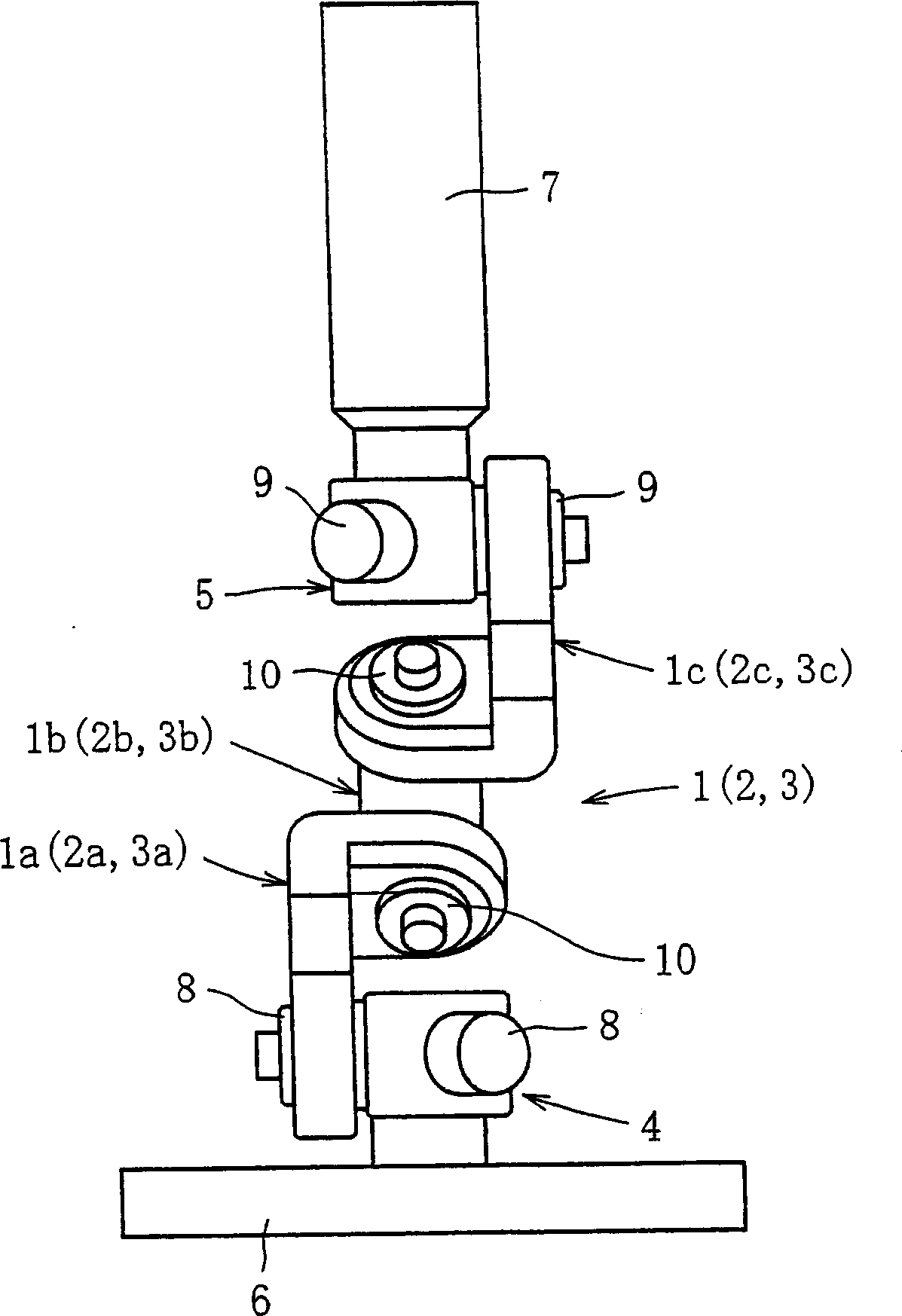

[0023] figure 1 The illustrated embodiment includes three sets of linkages 1-3 used, for example, as parallel linkages or robotic joints to perform complex machining or handling of items in three dimensions with high speed and high precision. .

[0024] The input member 6 and the output member 7 are connected together by three sets of linkage mechanisms 1-3 (first to third linkage mechanisms), each of which has a geometrically identical shape. The input part 6 is mounted on an input-side part of the device in which the operating device is incorporated, wherein said input-side part is, for example, a stationary part. The output member 7 is connected to an output side part of the device, wherein said output side part is for example a movable part. In this embodiment, as shown, the input member 6 has a disc-like shape and the output member 7 has a shaft-like shape.

[0025] Each link mechanism 1-3 forms a three-link chain, including an input link 1a (2a, 3a), a central link 1b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com