Battery pack

一种电池组、电池组件的技术,应用在电池组零部件、二次电池、原电池到电池分组等方向,能够解决尺寸误差高度偏差等问题,达到安装作业容易、防止噪音发生、防止晃动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

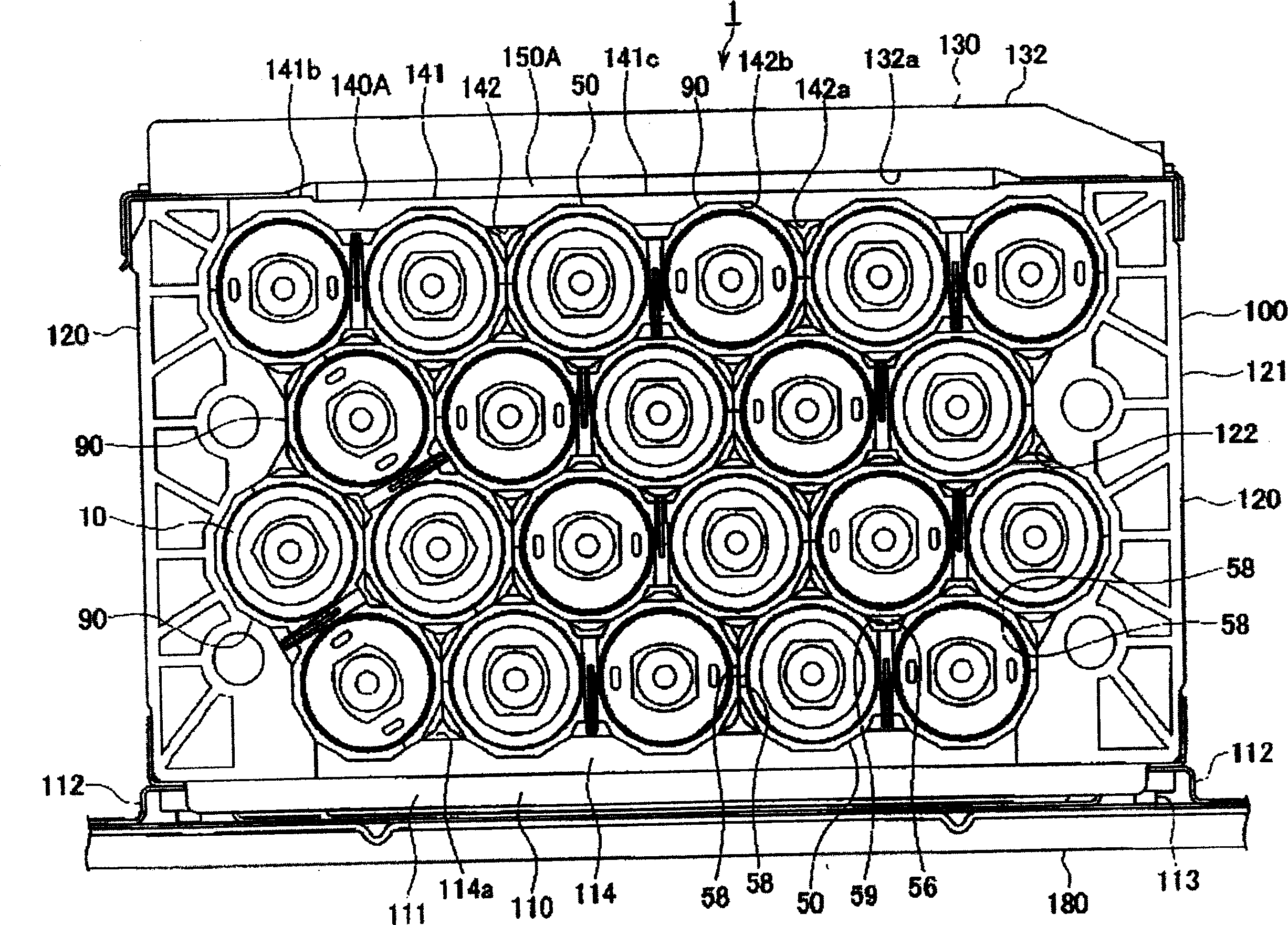

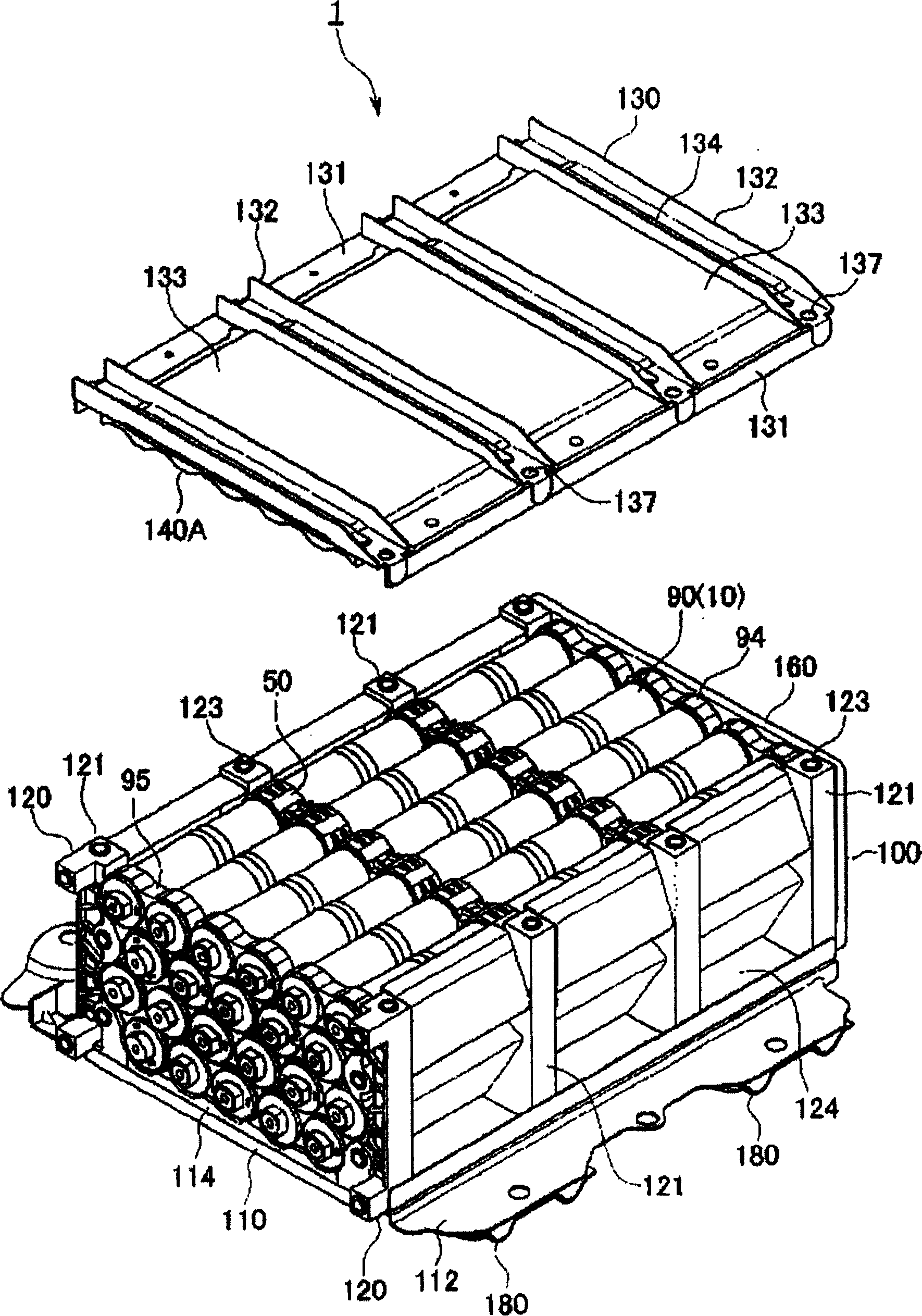

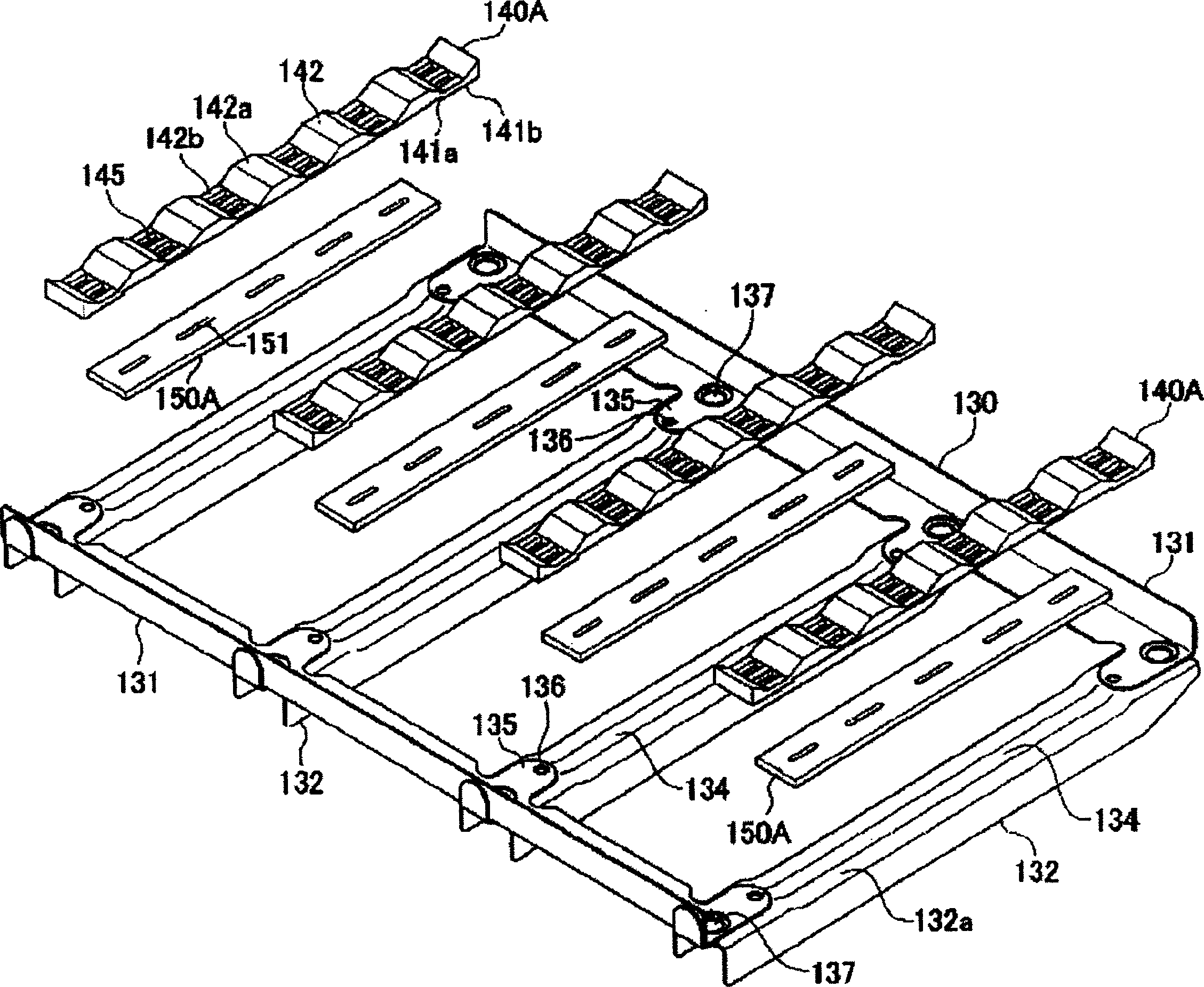

[0023] First, refer to Figure 1 to Figure 7 The accompanying drawings illustrate Embodiment 1 of the battery pack of the present invention. The battery pack 1 of this embodiment is mounted on the back of the seat of an electric vehicle. figure 1 It is a schematic front view of a battery pack 1 in which a plurality (22 in this embodiment) of battery modules 10 are accommodated in a battery case 100 so that their axial directions are parallel to each other. In this battery pack 1 , as shown in FIG. 5 , every two battery modules 10 are bundled with grommets (holding members) 50 in advance to form a battery module unit 90 . Additionally, if figure 1 As shown in , the outer surfaces of the grommets 50 of the battery assembly units 90 adjacent to each other are laminated so that the outer surfaces of the grommets 50 are in contact with each other. According to this configuration, the axial directions of the respective battery modules 10 are arranged parallel to each other, a cer...

Embodiment 2

[0042] [Example 2] Below, refer to Figure 8 , Figure 9 The accompanying drawings illustrate Embodiment 2 of the battery pack of the present invention. The battery pack 1 of the second embodiment differs from the structure of the first embodiment only in the upper frame 130 of the battery case 100, the pressing member 140B, and the elastic body 150B. Since the other configurations are the same as those of the first embodiment, the same reference numerals are attached to the same parts, and the description thereof will be omitted. In the battery pack 1 of Embodiment 1 described above, the pressing member 140A and the elastic body 150A are preinstalled on the upper frame 130 , while in the battery pack 1 of Embodiment 2, although the elastic body 150B is preinstalled on the upper frame 130 , but the pressing member 140B is not installed on the upper frame 130 , and is only placed above the guard ring 50 , the process wire cover 94 , and the cover 95 of the uppermost battery m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com