Annule type aplanatic spherical lens

A spherical lens and aspheric aberration technology, applied in optical components, optics, instruments, etc., can solve the problems of high cost, complex processing of aspheric lenses, and limited imaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0037] The first preferred embodiment: Suppose it is required to design a lens with f=60, F=3.75 and spherical aberration less than 0.30.

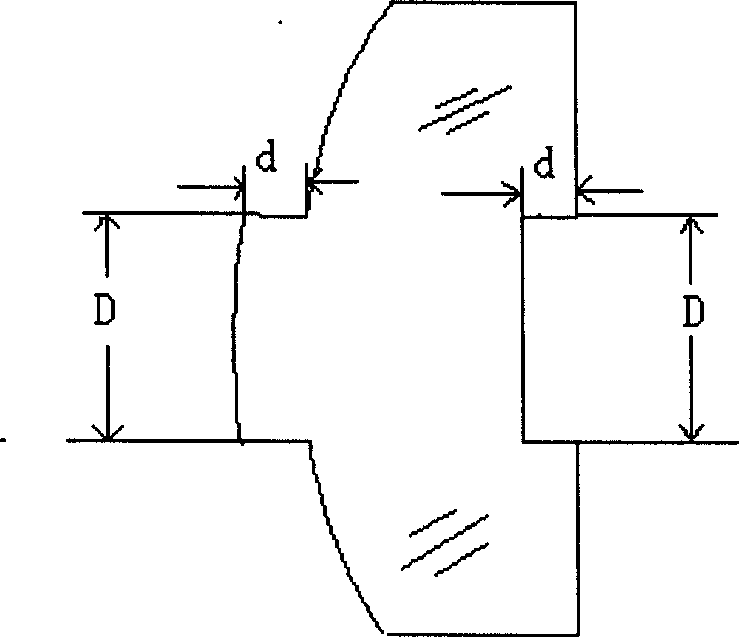

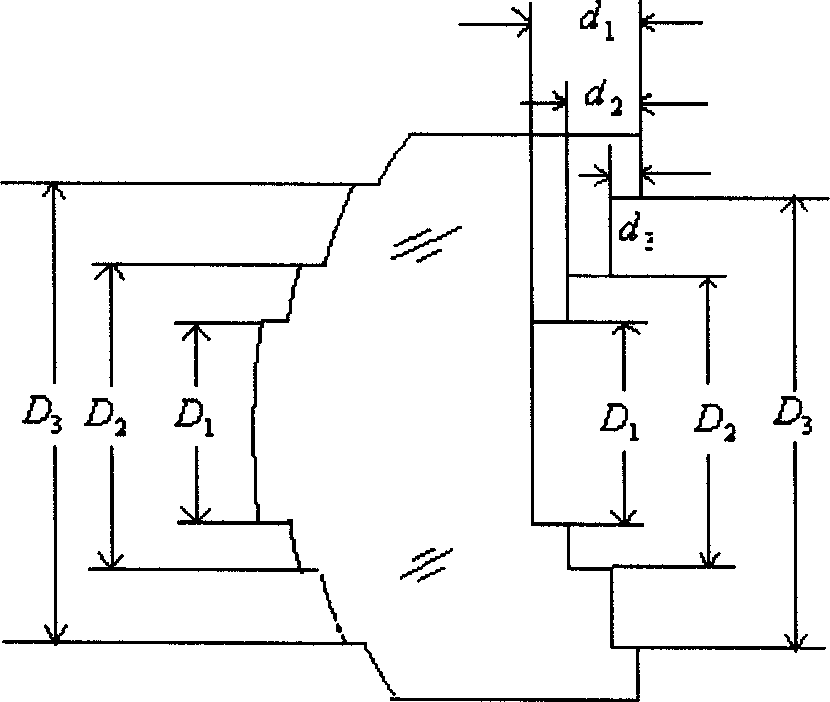

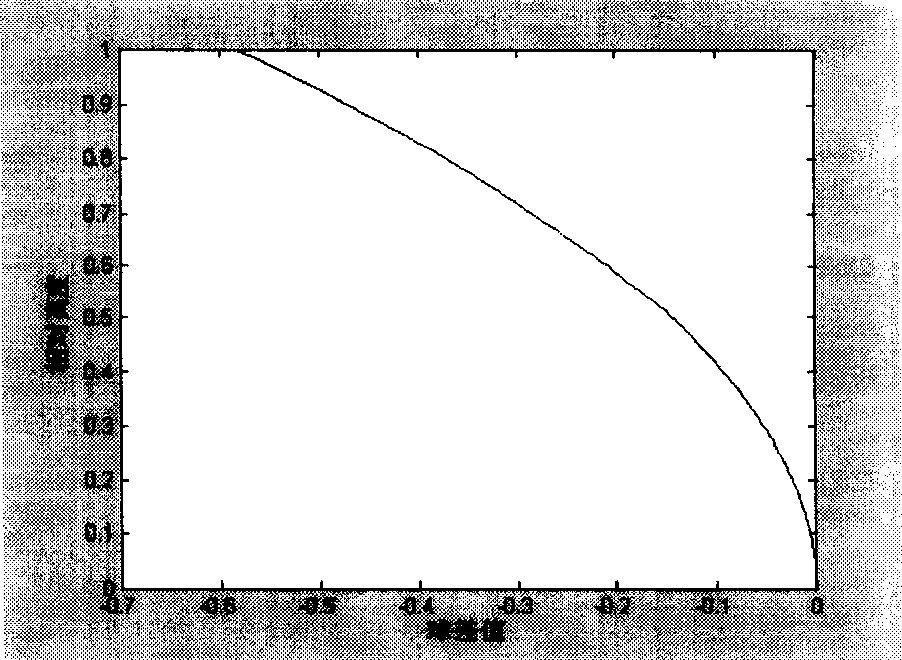

[0038] First, according to the above design requirements, a plano-convex lens with structural parameters as shown in Table 1 is selected as the basic lens of this preferred embodiment, and the convex surface is the light incident surface. Table 2 lists the spherical aberration values when a beam of monochromatic parallel light (λ=587.5618nm) passes through the plano-convex lens, and its spherical aberration curve can be found in figure 2 , for point plots on the axis see Figure 5 , the optical transfer function curve see Figure 8 .

[0039] serial number

center thickness

Effective caliber

Glass grade

1

50.7998

6.0

16

ZF52

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com