Equipment and method for removing deposits created in electrolytic refining

一种电解精炼、沉积物的技术,应用在电解组件、电解过程等方向,能够解决烦人噪音、不能去除沉积物等问题,达到加速去除、避免机械应变、弯曲运动有效的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

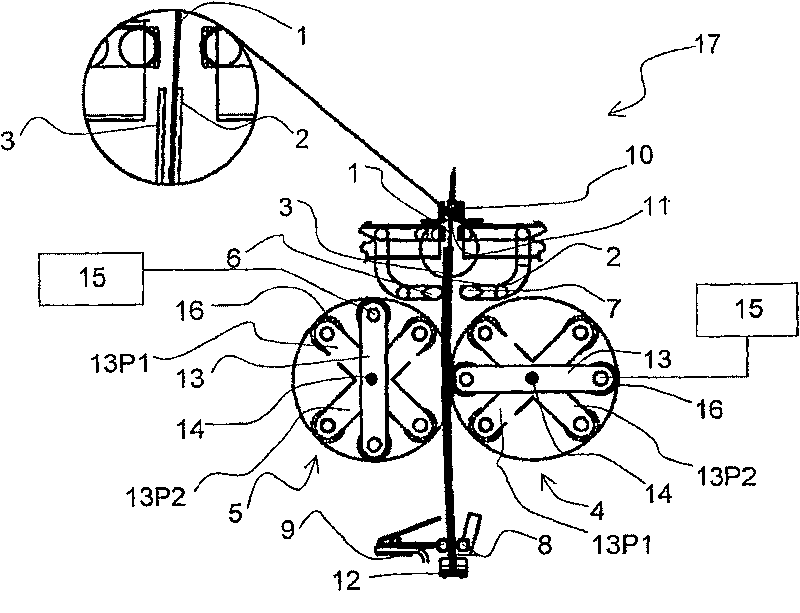

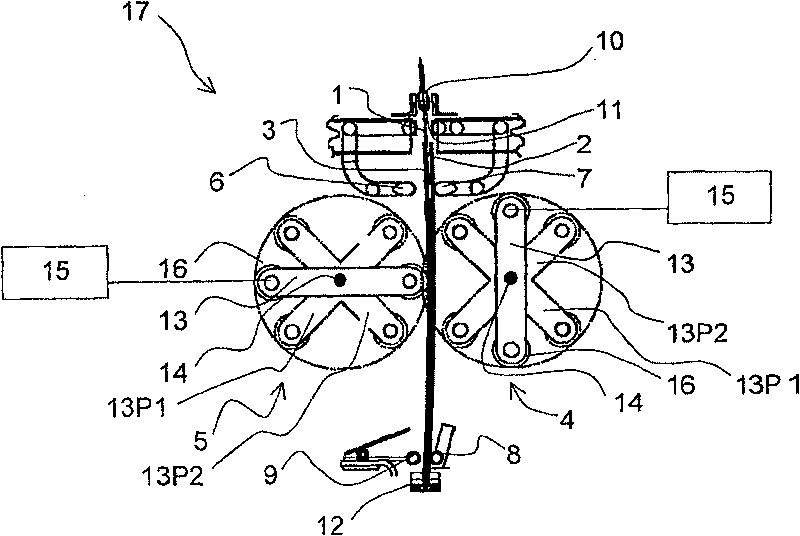

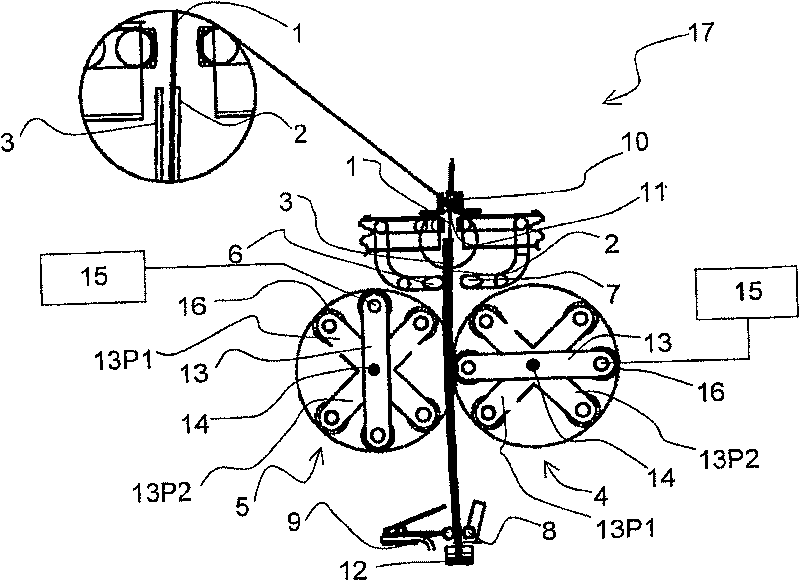

[0013] figure 1 and 2 A device is shown for removing deposits 2, 3 that accumulate on the surface of an electrode such as a cathode 1 made of stainless steel during electrolysis. According to the figure, the cathode 1 is transported from electrolysis to a stripping station 17 , for example by means of a conveyor 12 . According to this example, the cathode is supported at the support structure 10 of the stripping station located near the suspension rod 11 , ie at that end of the cathode which is above the electrolytic solution during the electrorefining process. Furthermore, during the removal process, the cathode 1 is supported by support elements 6, 7, 8, 9 provided in the stripping station, such that the cathode is in a vertical position during the removal of the deposits. By means of the supporting elements, the cathode can be supported on both sides of the cathode, or only at desired points. In order to remove the accumulated deposits 2, 3 on both sides of the cathode 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com