Multihead birow quilting embroidering integrated machine

An all-in-one, multi-head technology, used in the field of quilting and embroidery machinery, can solve the problems of high labor intensity, high production cost, large needle spacing, etc. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

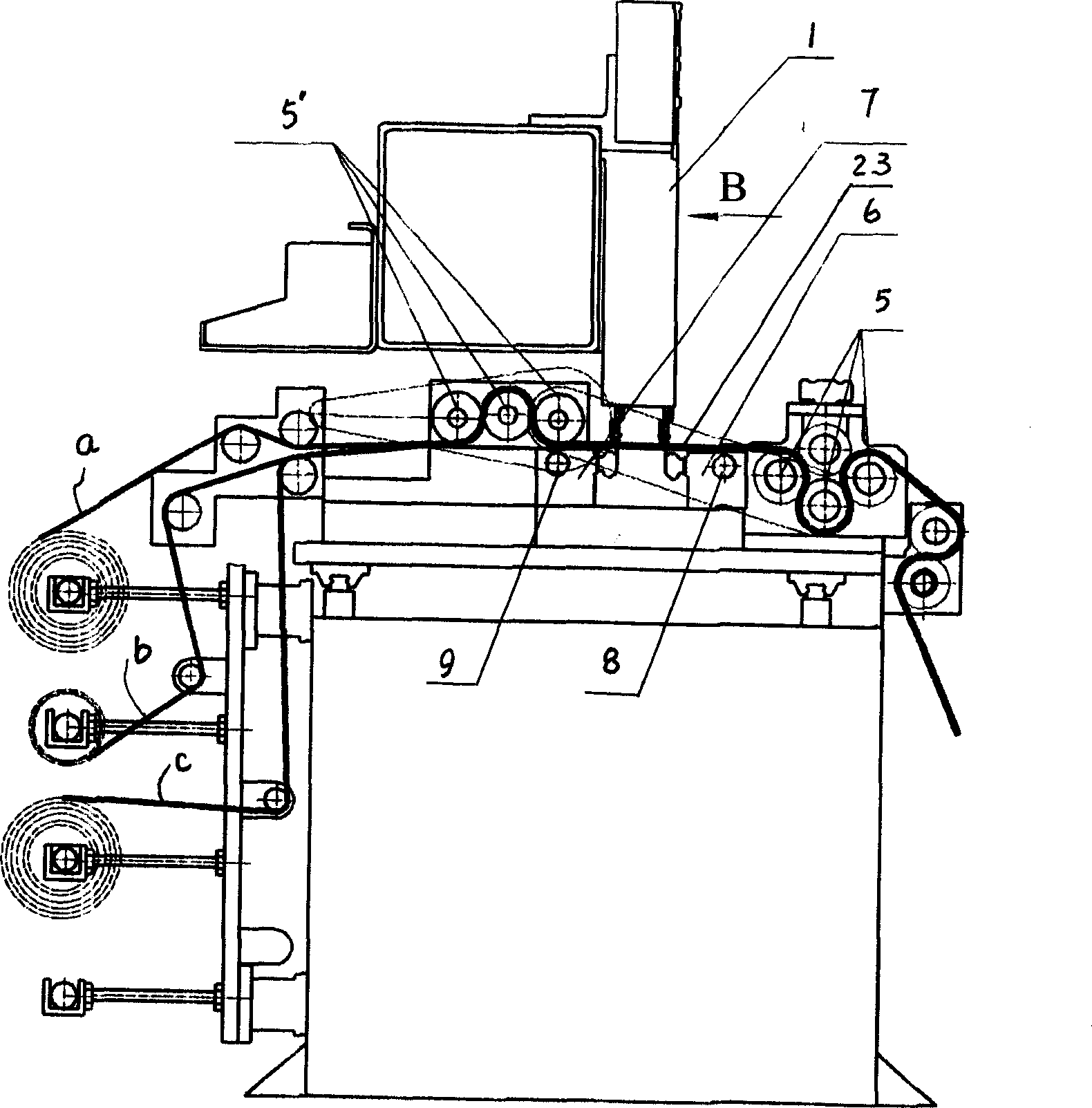

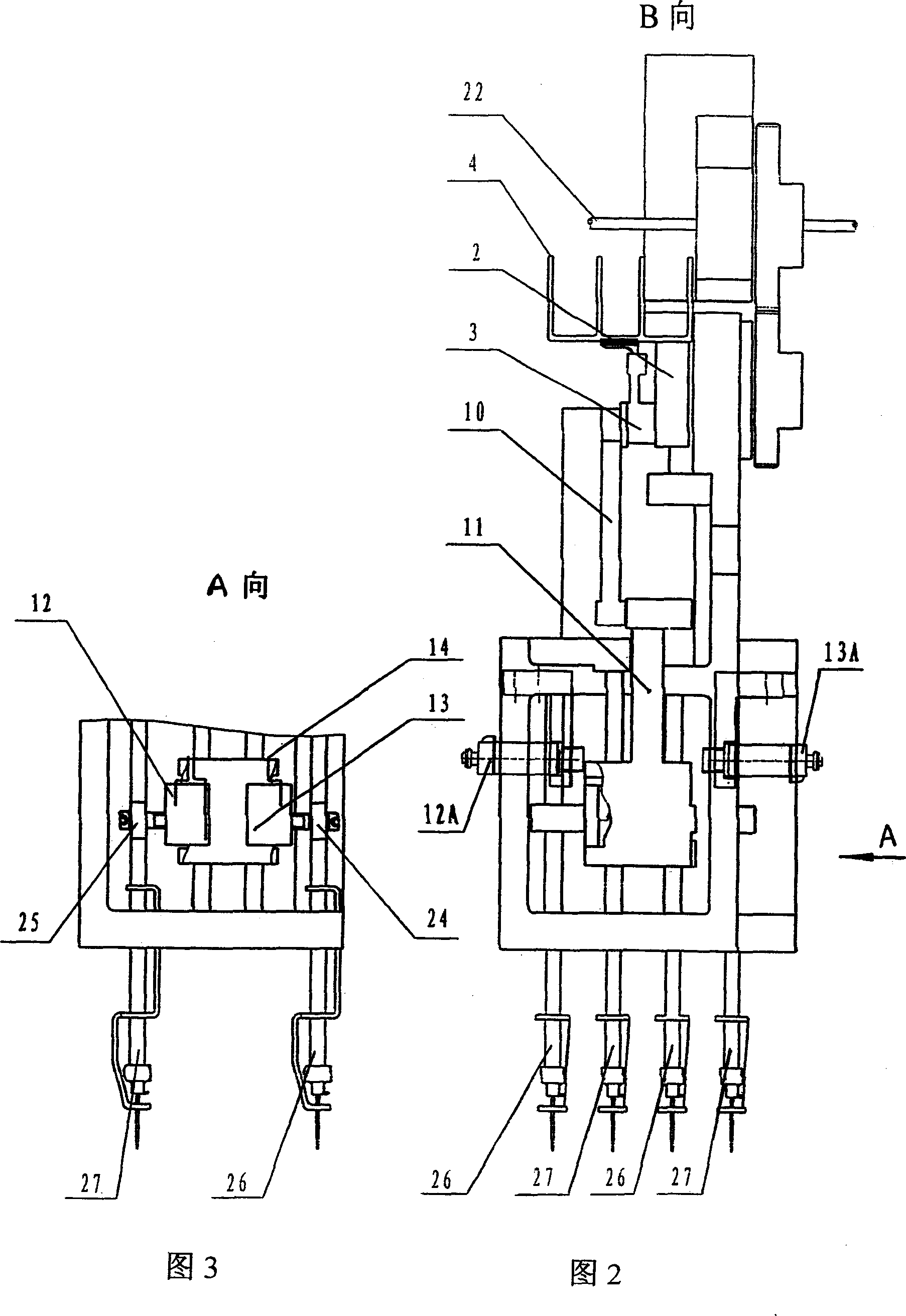

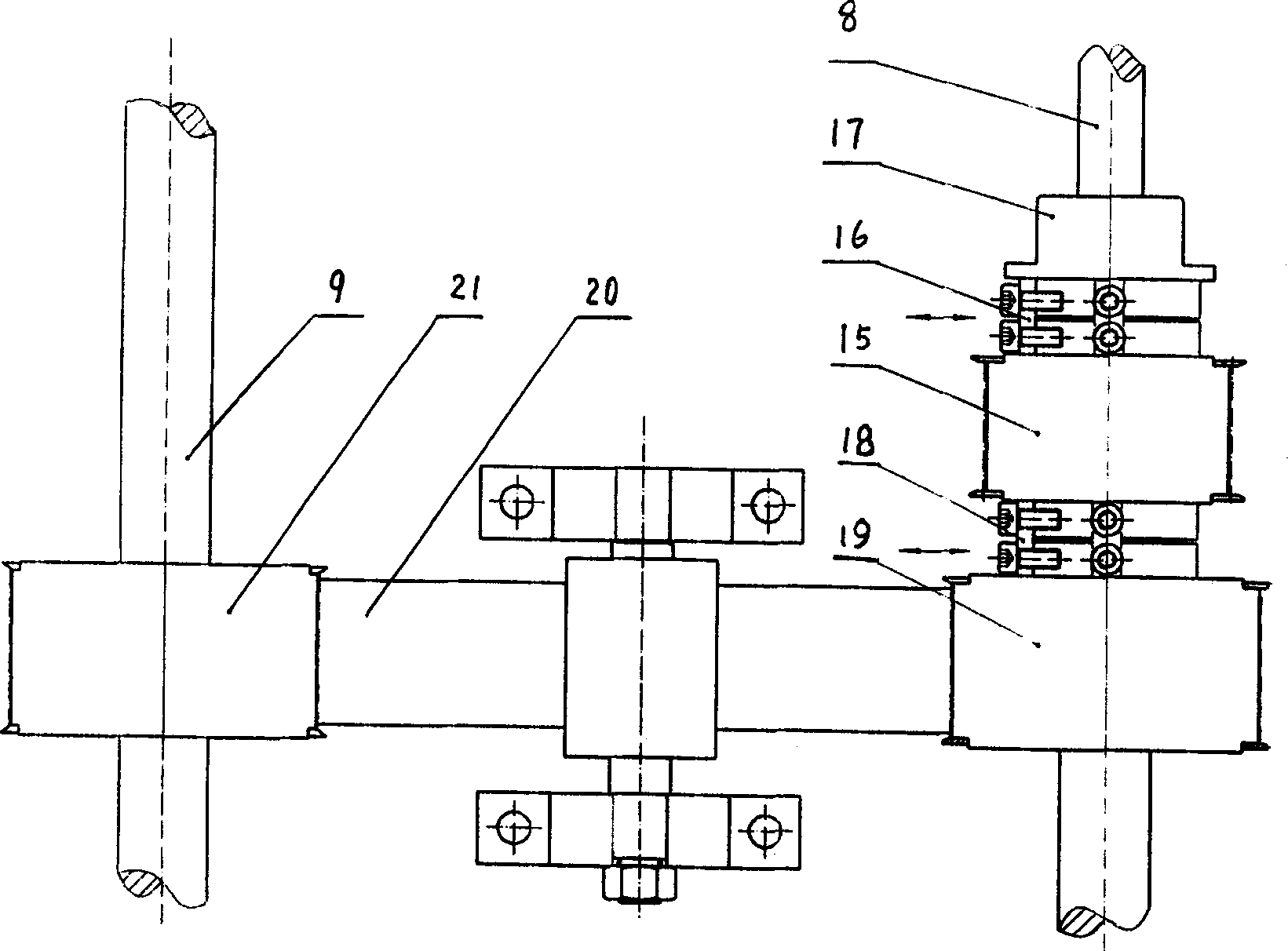

[0017] Attached below Figure 1 to Figure 4 The structure of the embodiment of the present invention is further described.

[0018] figure 1 It is a schematic diagram of the process of superimposing fabric a, interlayer cotton b and base fabric c through the machine, conveying, quilting, embroidering and outputting. The three-layer material is folded into one by the cloth-feeding guide roller 5 ', and is quilted and embroidered into one when passing through the needle plate 23, and then output by the cloth-out guide roller 5. The cloth guide roller 5 is arranged in a rhombus by four roller shafts up and down, left and right, wherein the upper edge of the left and right two roller shafts is flush with the needle plate 23 planes. Front row rotary hook box 6 and rear row rotary hook box 7 are housed on the frame below machine head 1, and rotary hook box main shafts 8, 9 are respectively housed on the two rotary hook boxes, and the two rotary hook box main shafts are respectivel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap