Device and method for machining long workpieces fixed between two rotating bearings

A technology with long workpieces and rotating shafts, which is applied in the field of high-speed machining, and can solve problems such as not allowing effective suspension of workpieces, and achieve the effects of eliminating shortcomings, high speed, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

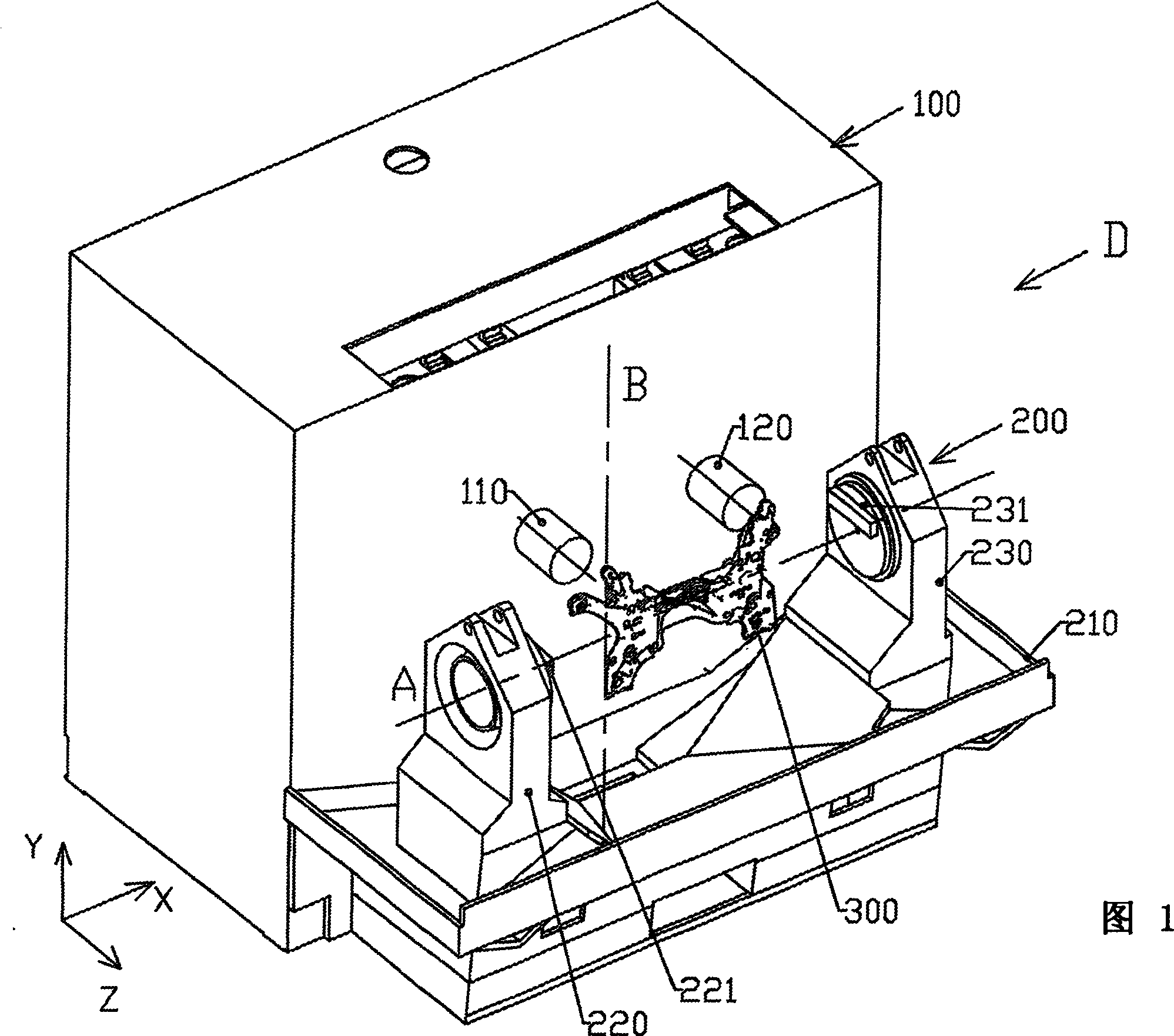

[0048] As shown in FIG. 1 , the machining apparatus generally designated D includes a machine tool 100 and a workpiece holding device 200 in which a workpiece 300 is shown.

[0049] As shown, machine tool 100 is a machining machine tool that has very high speed actuation and maintains an electric spindle for supporting a tool, not shown, along three axes X, Y, Z and independently of each other. The two carriages 110 and 120 are actuated.

[0050] According to a technical option that enables the precision and speed of machining operations to be optimized, the machine tool shown is of the type that it includes guides that are connected with the two carriers along three Corresponding to the linear motion of the two axes, wherein these guide devices include a pair of guide rails, and they realize the above-mentioned independent motions by means of linear linear motors.

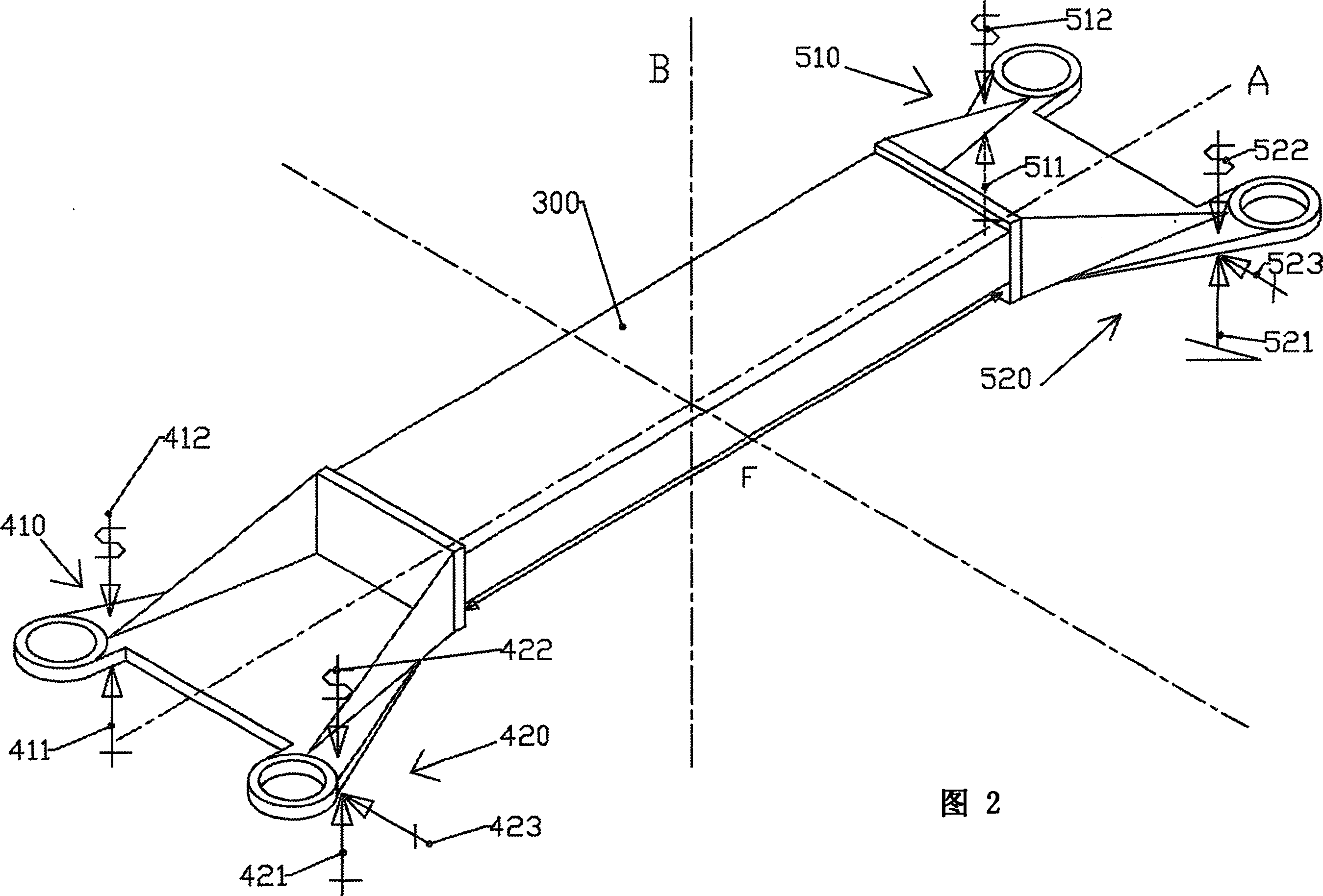

[0051] Although, due to the length of the separation distance between the two ends to be machined, the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com