Hemming device for wheel housing of vehicle

一种折边装置、轮罩的技术,应用在车轮、车辆部件、运输和包装等方向,能够解决花费很长、系统损坏、经济损失等问题,达到提高可操作性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

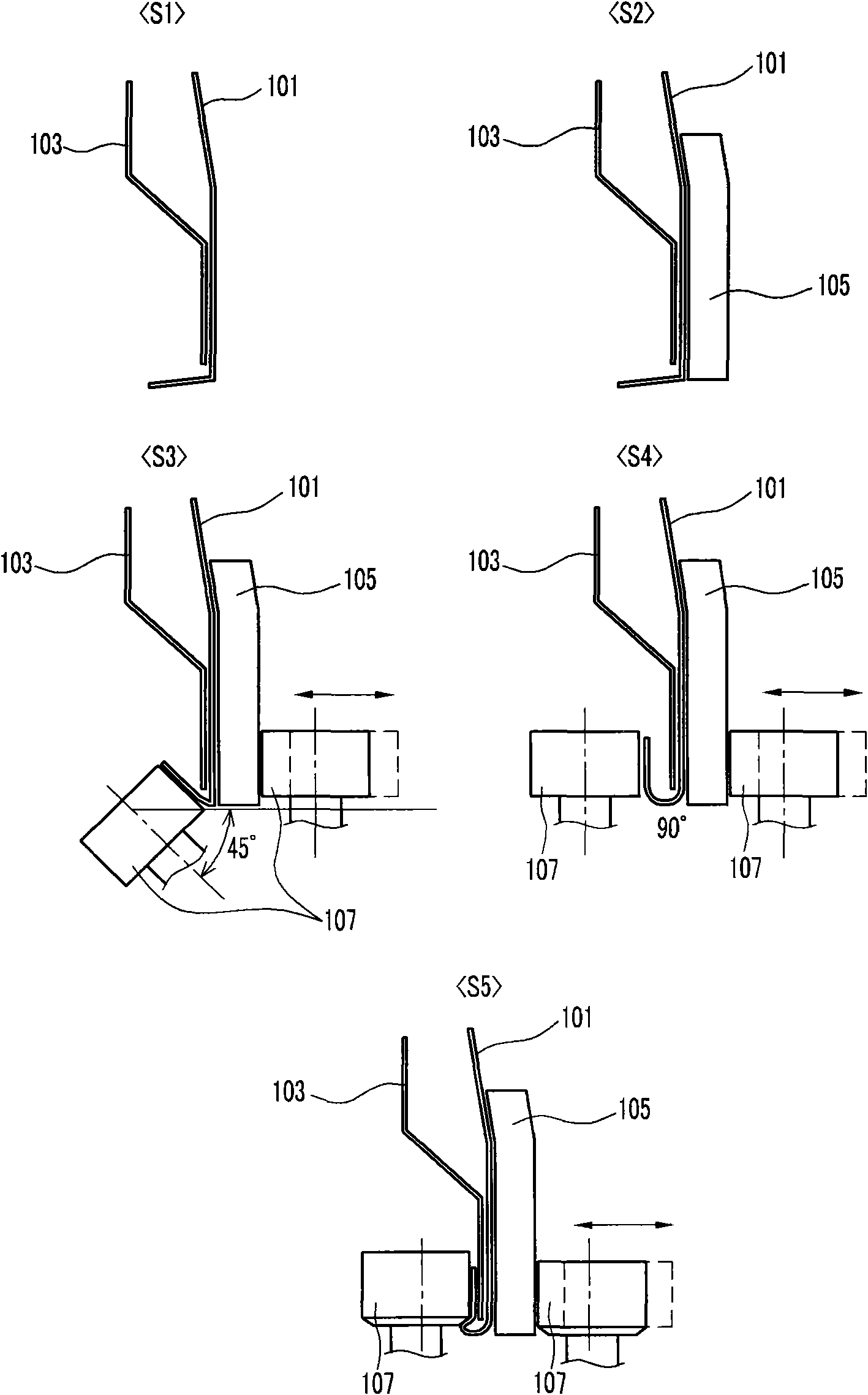

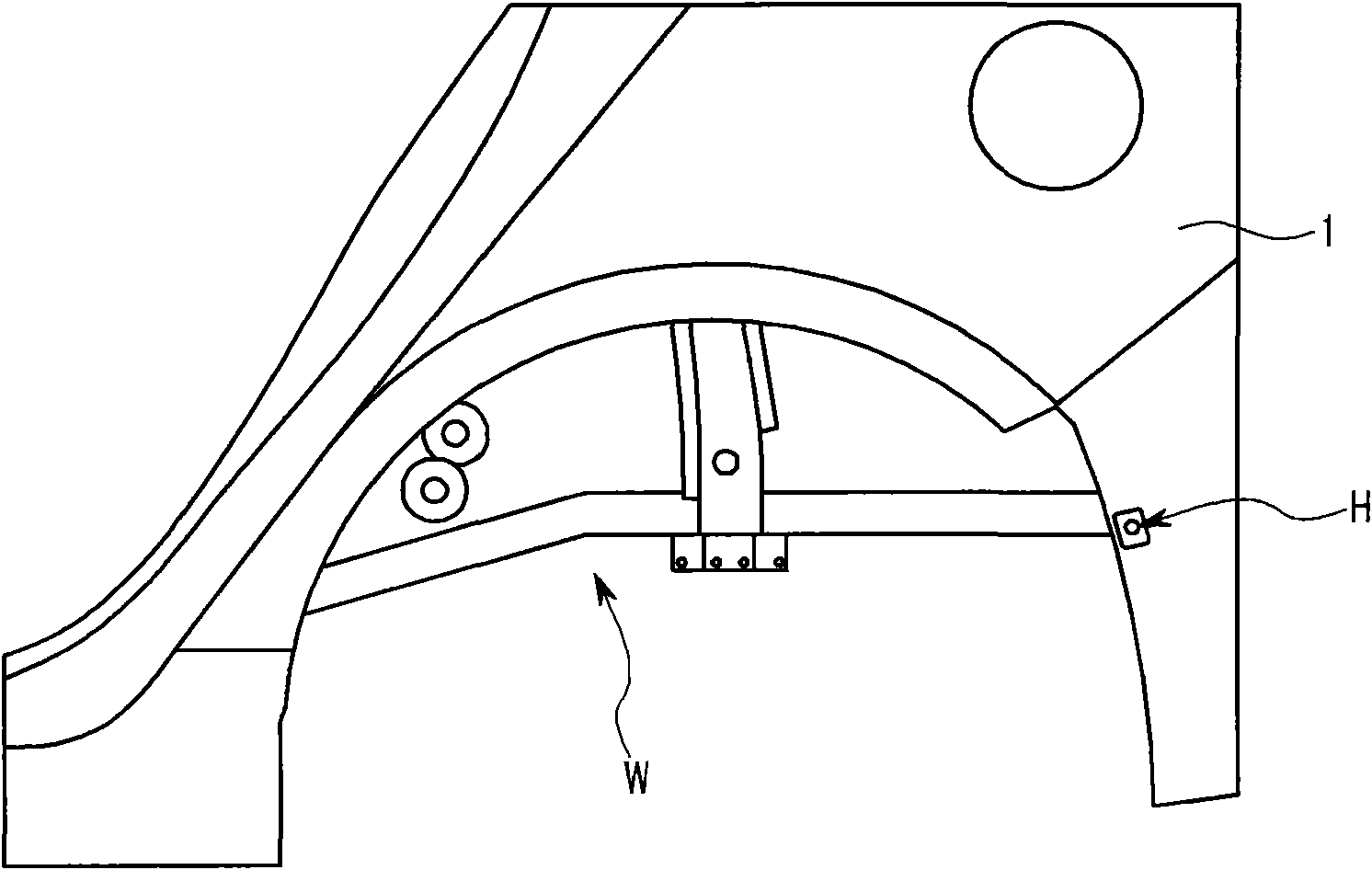

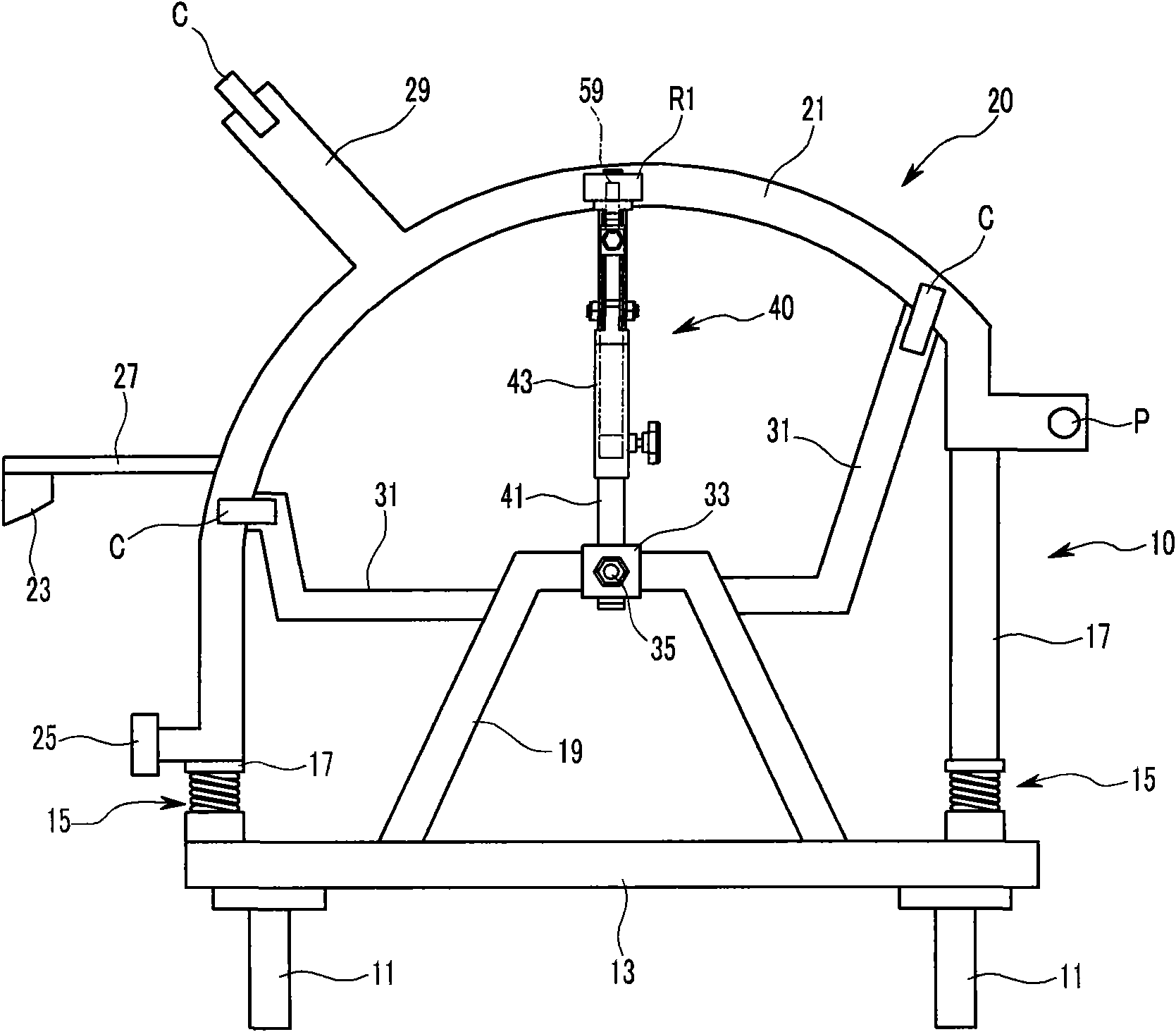

[0034] As further described herein, the present invention is characterized by a hemming device for a wheel well of a vehicle which, while supporting the outer surface of the outer panel of the wheel well of a vehicle body, performs hem. The hemming device includes a mounting frame, a hemming seat, a seat fixing part and a hemming roller unit.

[0035] The hem shoe unit fixes the hem shoe to the upper portion of the mounting frame, and supports the wheel house by connecting the hem shoe to the outer surface of the outer panel of the wheel house. The seat fixing parts are provided on both sides of one section of the mounting bracket, and fix the hemmed seat to the outer panel of the wheel house. The hemming roller unit is installed on the upper end of the upper part of the installation frame by a rotating clamper, and performs hemming on the inner panel and outer panel of the wheel house by manually rotating the two hemming rollers.

[0036] In another embodiment, the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com