Surface cleaning apparatus

A technology for surface cleaning and equipment, applied in the direction of suction nozzles, etc., can solve problems such as inability to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

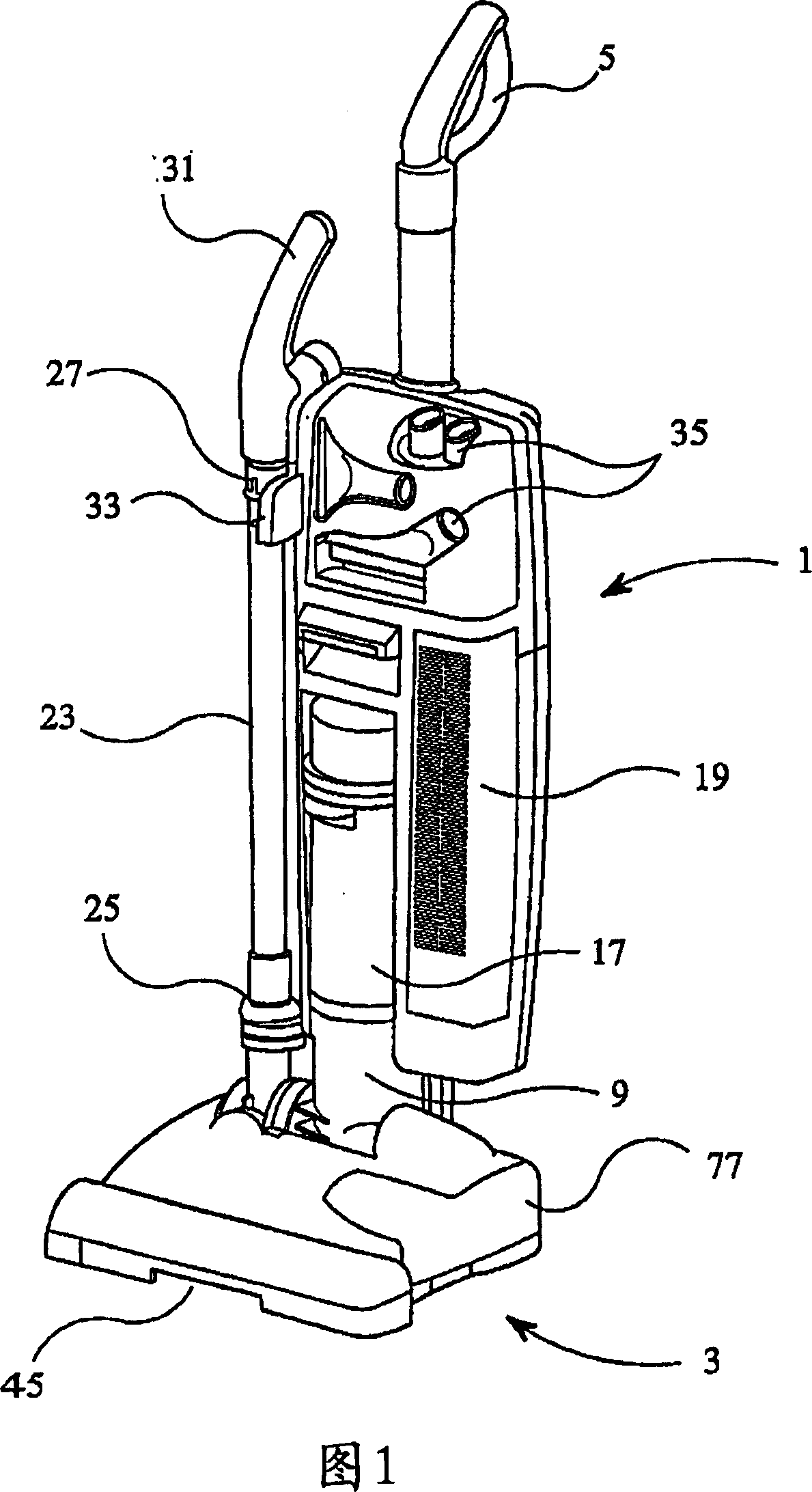

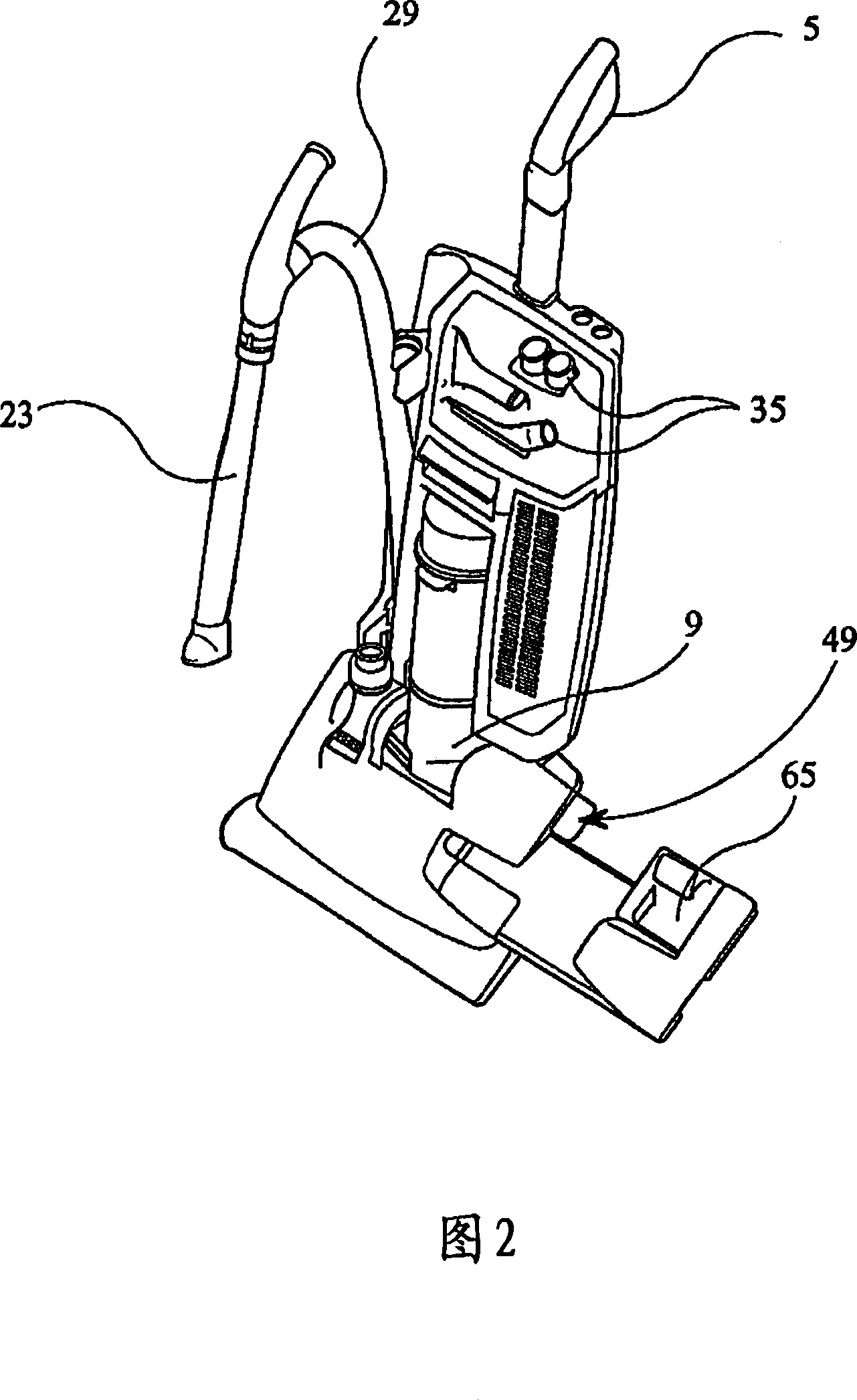

[0068] Referring to FIGS. 1 to 14 , a first embodiment of a surface cleaning appliance in the form of an upright cleaning appliance has a housing comprising a cleaner body 1 pivotally mounted on a debris retrieval body 3 . The cleaner body 1 and the debris retrieval body 3 are suitably molded from plastic.

[0069] The surface cleaning device has a handle 5 provided on the cleaner body 1 so that the surface cleaning device can be manipulated on the surface to be cleaned. The cleaner body 1 is pivotable relative to the debris retrieval body 3 so that the cleaner body 1 can be tilted backwards from the debris retrieval device. The pivoting facilitates movement of the surface cleaning device over the surface to be cleaned.

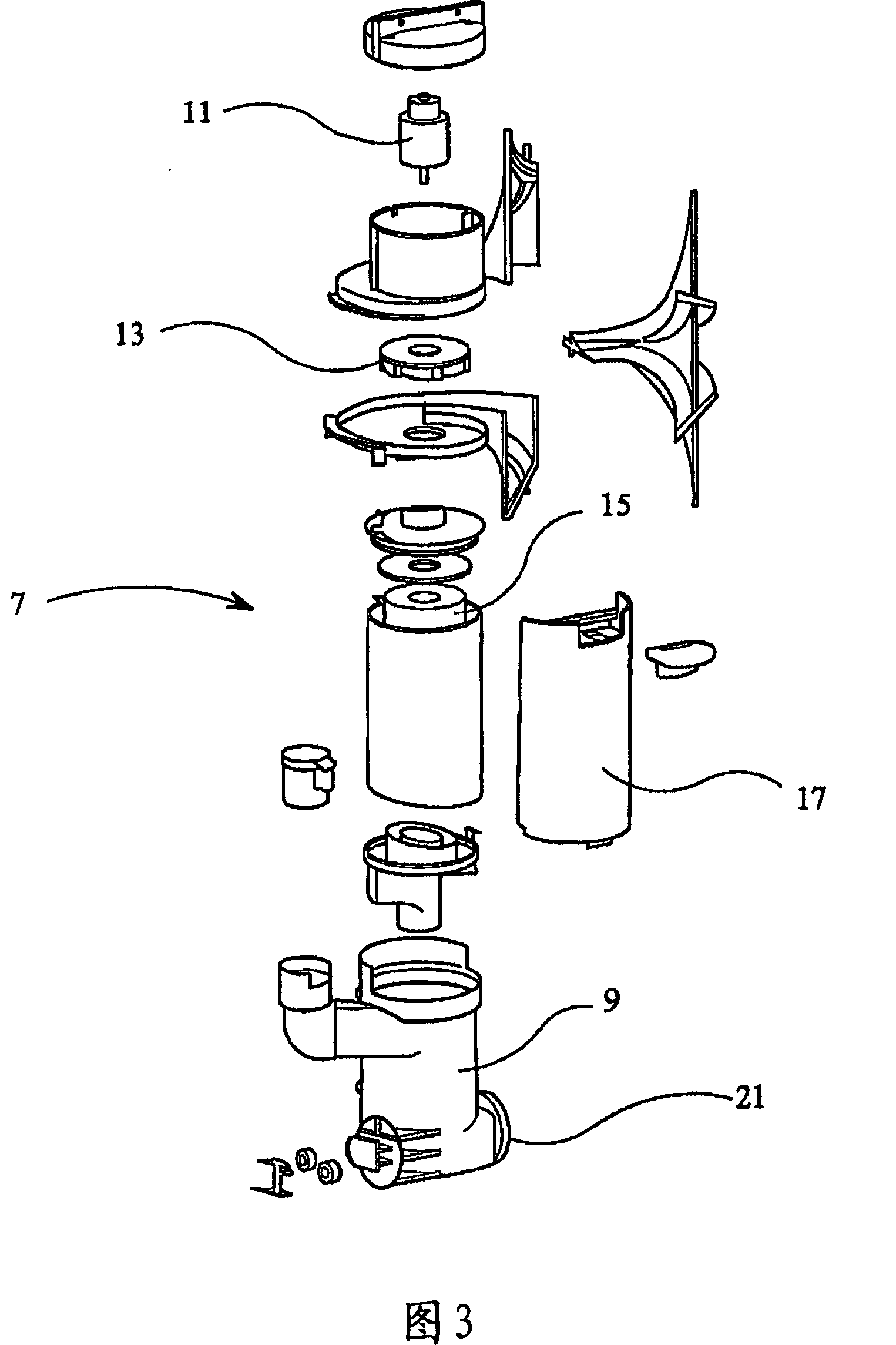

[0070] The cyclonic suction generating assembly 7 is contained in the cleaner body 1 as known to those of ordinary skill in the art. As shown in FIG. 3 , the cyclonic suction generating assembly 7 comprises a cyclonic separator 9 equipped with a motor 11 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com