Downhole Fluid Treatment Tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

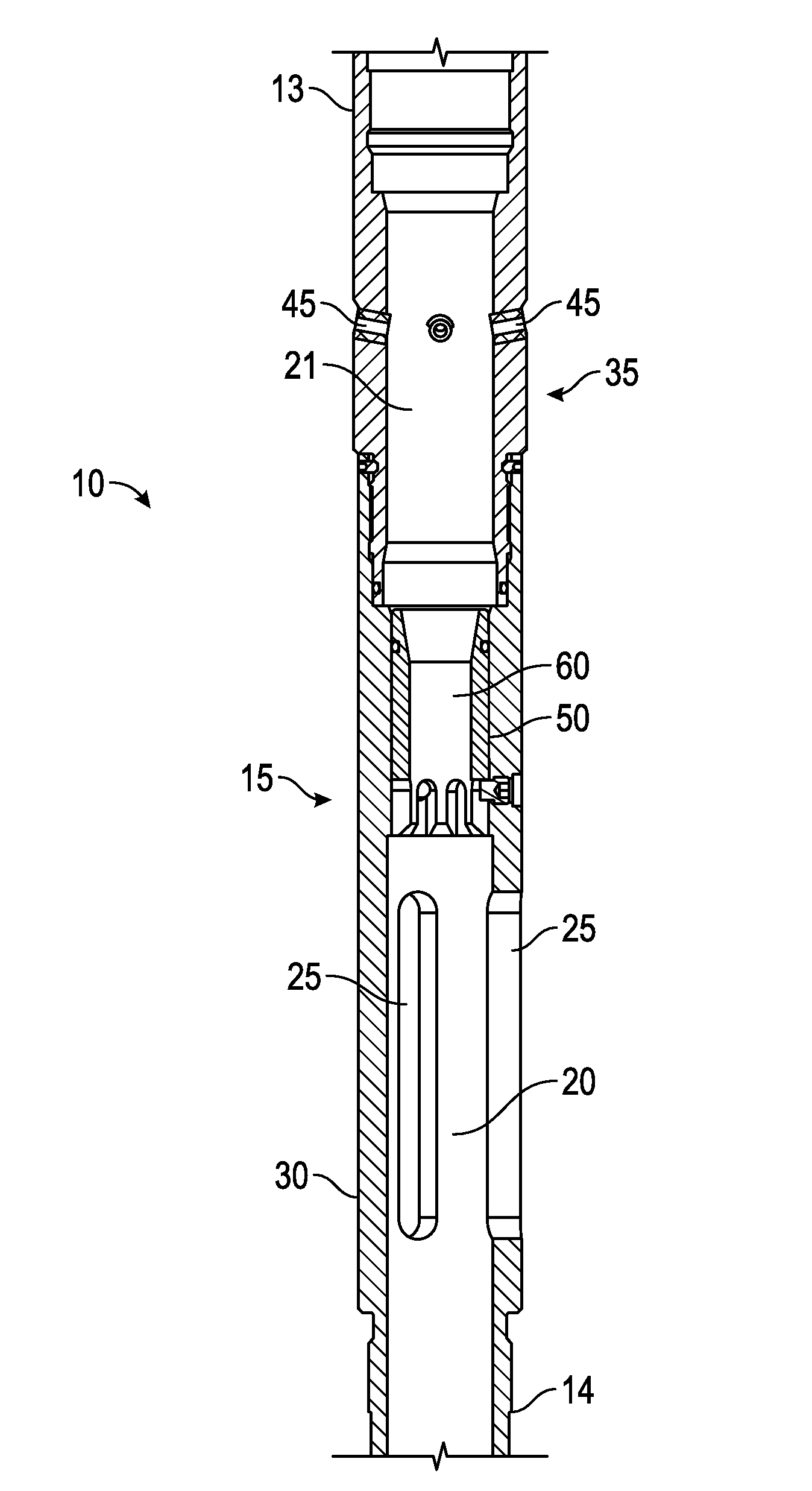

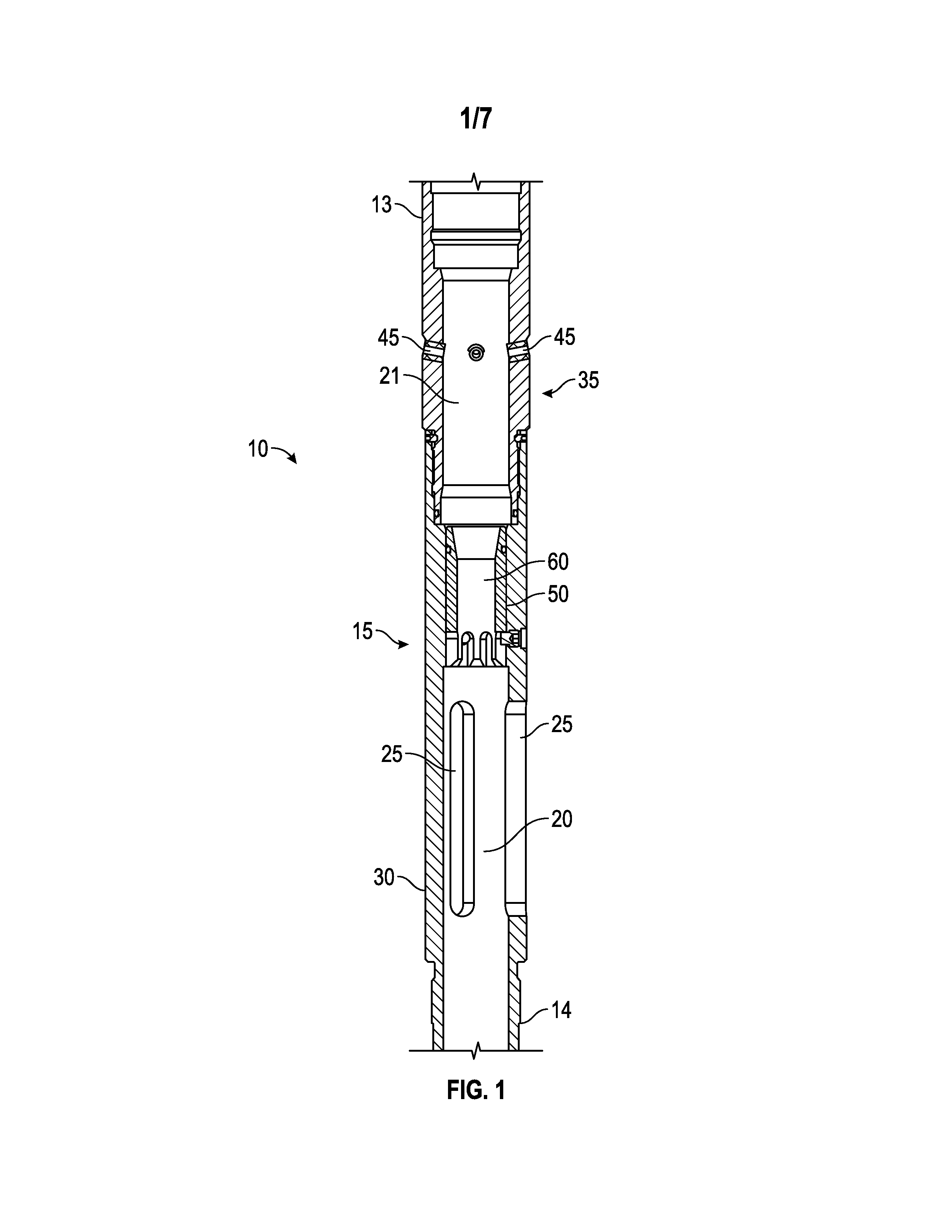

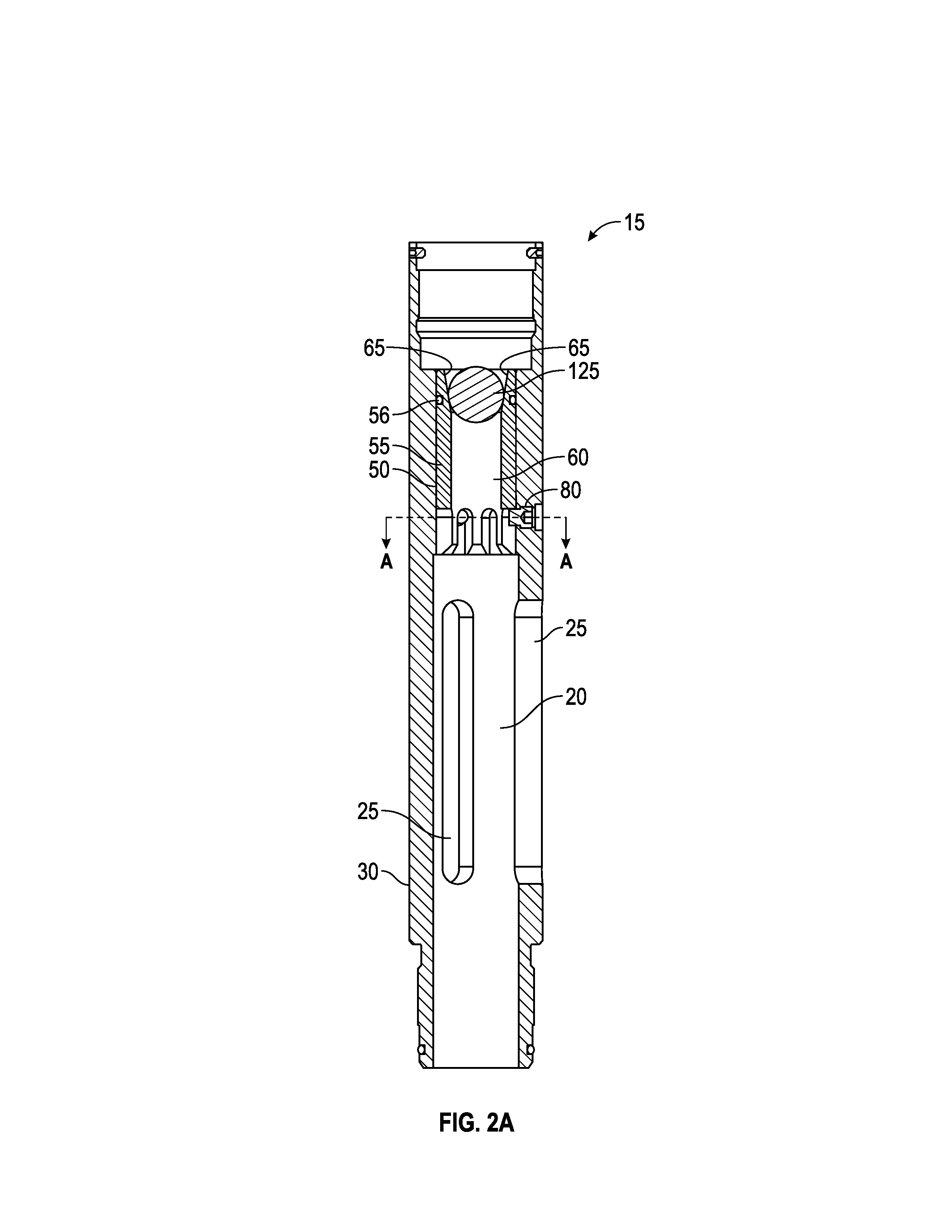

[0030]Generally, the present invention provides a device and method for providing multiple tubing-conveyed fluid pathways through a single tool assembly. Delivery of fluid though a first fluid pathway effects a first fluid treatment within a wellbore interval, while delivery of fluid through a second fluid pathway effects a second fluid treatment within the wellbore. A ball valve allows for diversion of fluid from the first fluid pathway to the second fluid pathway upon delivery of a deformable ball to the ball valve. Hydraulic pressure is applied to force the ball against the seat and thereby build up pressure within the tool assembly and / or tubing string above the sealed ball seat. Once treatment through the second fluid pathway is complete, the deformed ball may be removed, either by reverse circulation from the tool assembly to surface, or may be forced through the seat by application of increased hydraulic pressure so as to deform the ball. Such deformable balls may be engineer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com