Method for partial metallization on paper

A metal material, partial plating technology, applied in the field of partial metal plating on paper and packaging materials, can solve the problems of unfavorable product anti-counterfeiting, monotonous paper color and pattern, and can not fully meet the packaging beauty and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Through the description of the preferred embodiments of the present invention, the advantages of the present invention can be seen and understood more clearly.

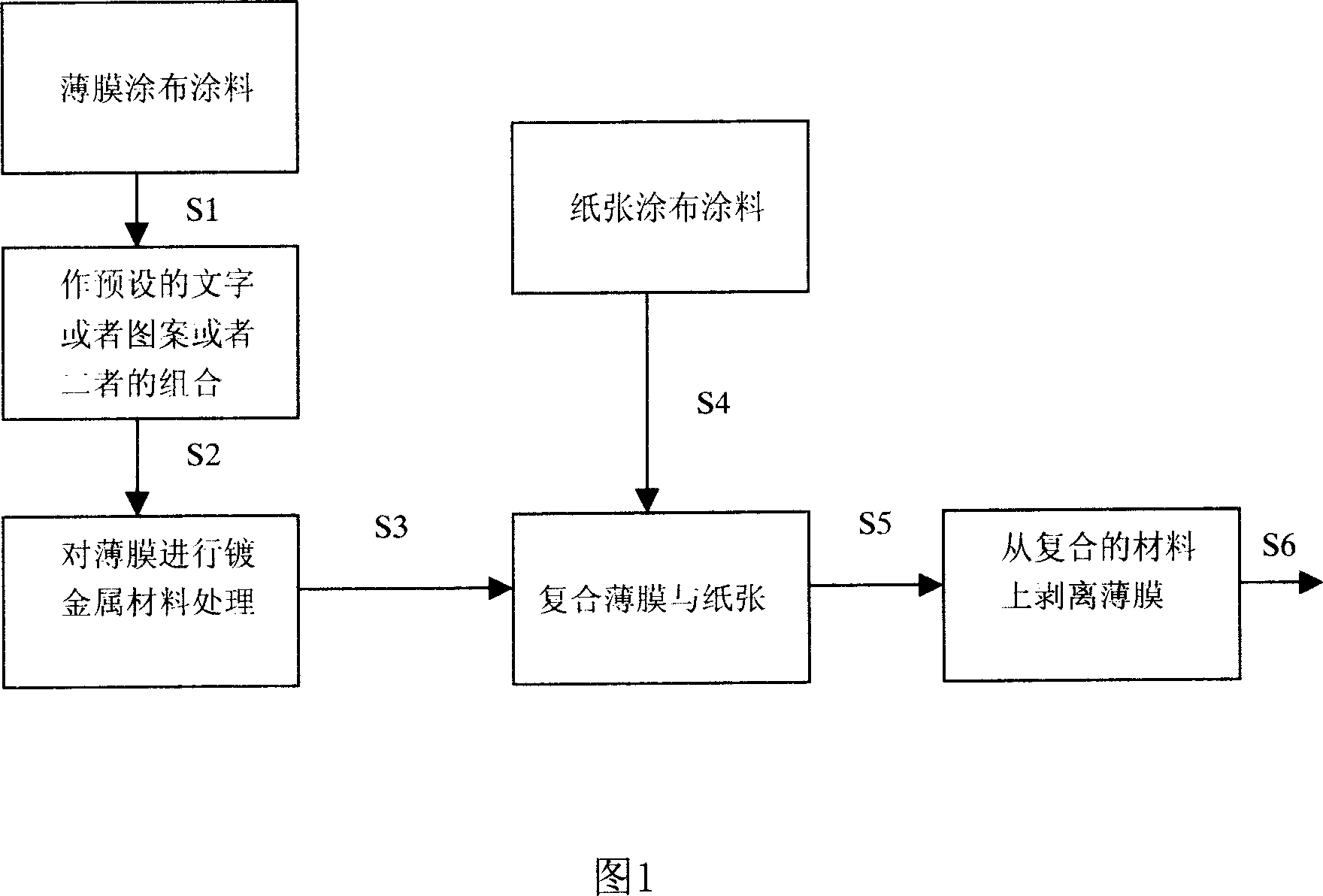

[0031] As shown in Fig. 1, the method of the present invention is at first step s1, the film surface is evenly coated with paint; followed by step s2, making a combination of preset characters, patterns or character patterns on the film coated with paint; and then It is step s3, printing metal material on the above-mentioned thin film. Step s4 is performed simultaneously with steps s1, s2, and s3, that is, evenly coating the paint on the base paper. After the above steps are completed, step s5 is carried out, and the film with characters and patterns is combined with the paper coated with paint to form a composite material, and the characters and patterns on the film are transferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com