Plating tank

A technology of electroplating tank and current, applied in the direction of plating tank, electrical components, electrolysis process, etc., can solve the problems of unable to prevent the plate-shaped workpiece W from shaking, unable to uniform quality, easy to break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

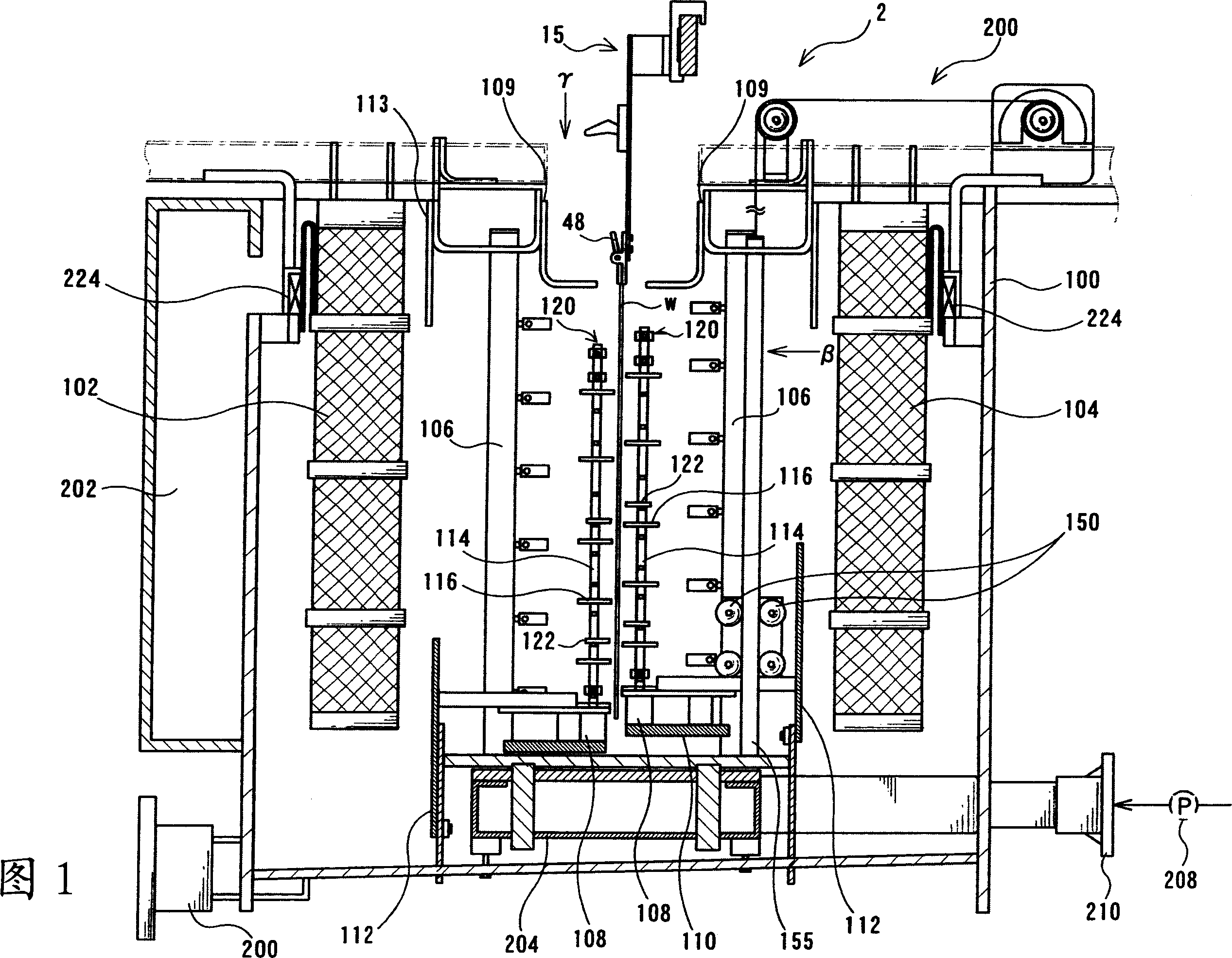

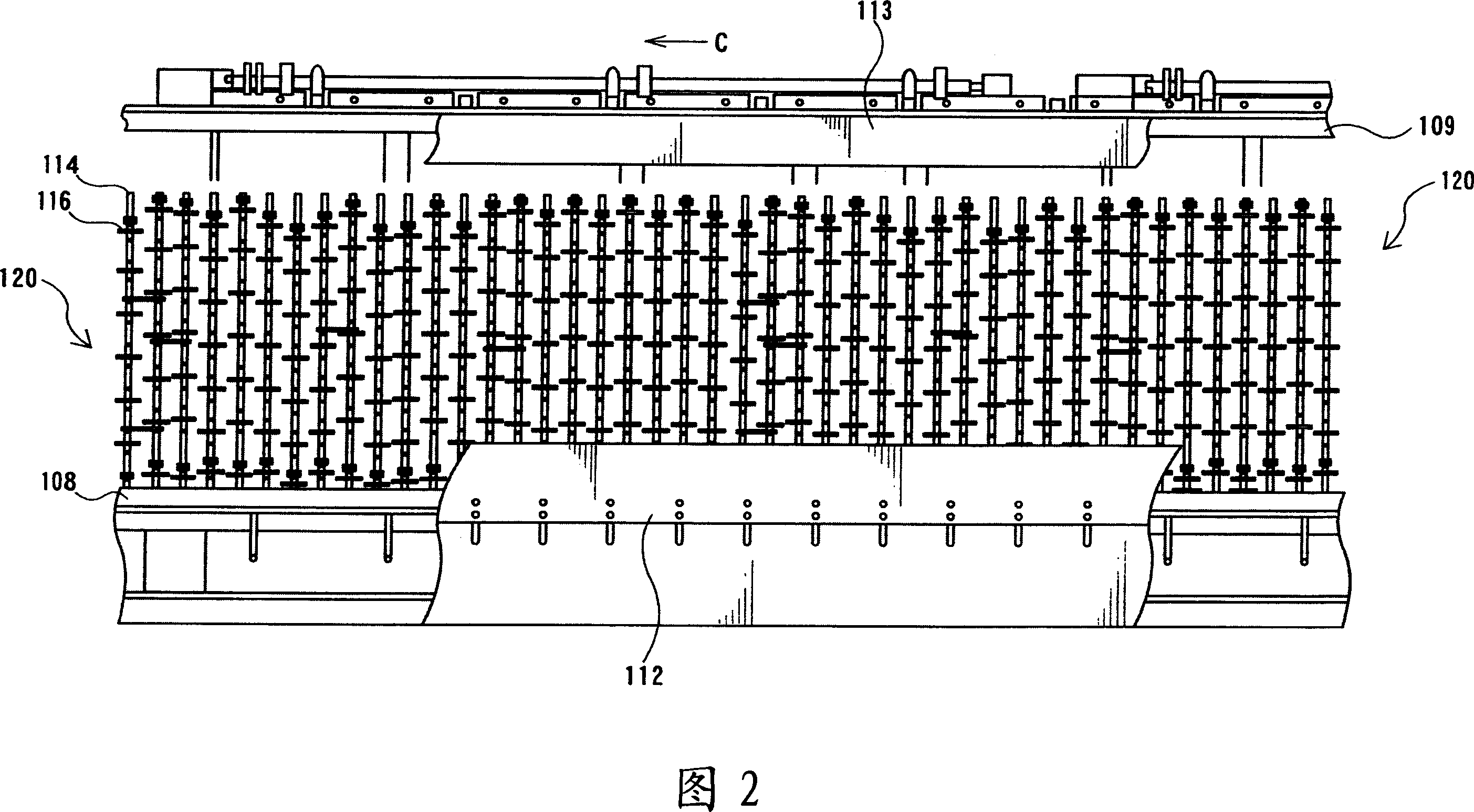

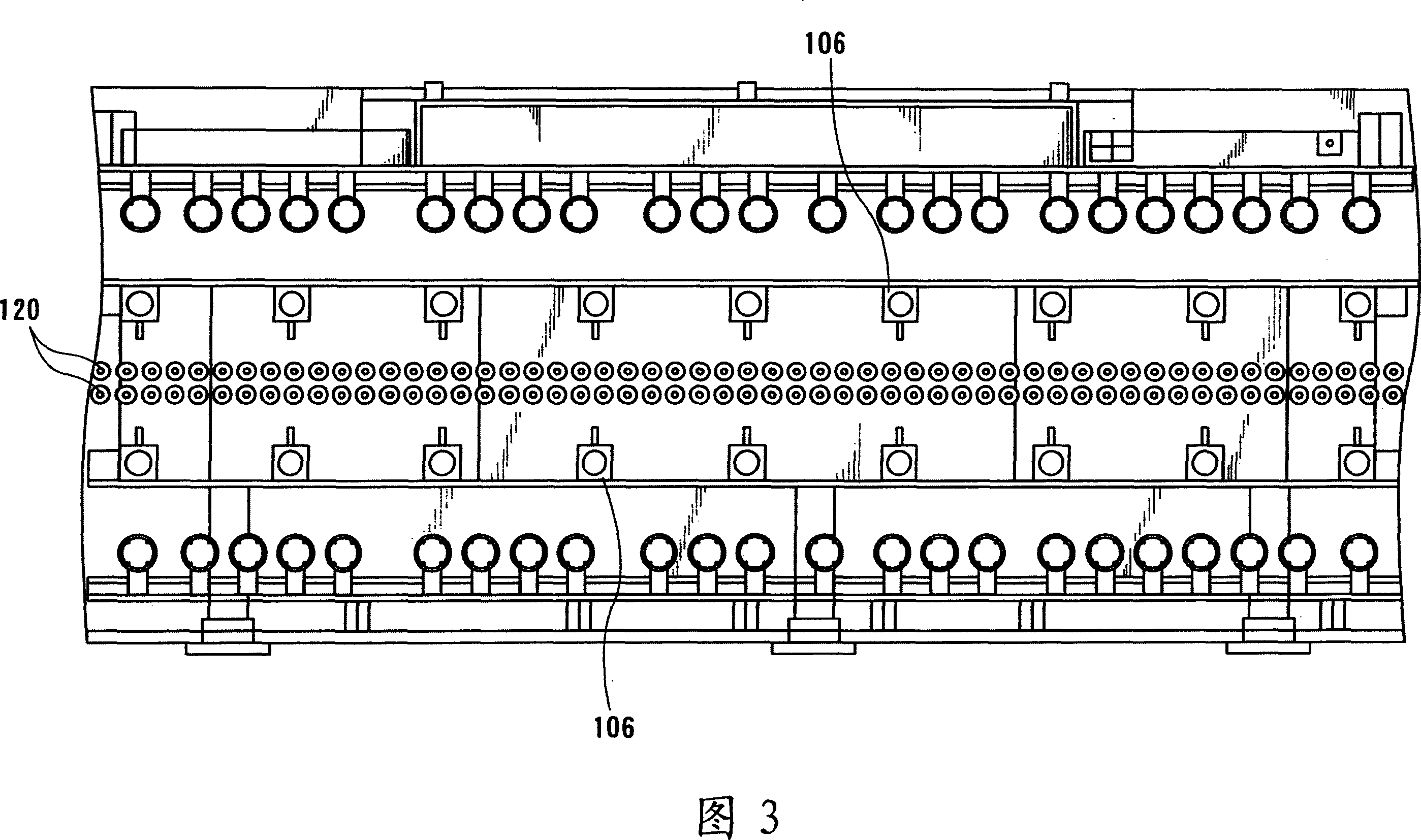

[0089] 1. Plating tank

[0090] The basic structure of the surface treatment device is the same as that shown in Fig. 14 and Fig. 15 . FIG. 14 is a plan view of the surface treatment device 300 viewed from above. FIG. 15 is a side view of the surface treatment device 300 shown in FIG. 14 viewed from the α direction.

[0091] As shown in FIGS. 14 and 15 , the surface treatment apparatus 300 has guide rails 10 to 13 for transporting a transport hanger 15 for holding a plate-shaped workpiece W such as a printed circuit board, and is provided along these guide rails. There are: pretreatment tank 1 for electroplating pretreatment process; electroplating tank 2 for electroplating process; recovery tank 3 and water washing tank 4 for electroplating post-treatment process; used for disassembly of plate-shaped workpiece W The unloading section 5; the stripping tank 6 for carrying out the peeling process (hanger return process) of the plating layer attached to the transport hanger 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com