Butterfly valve core and butterfly valve thereof

A butterfly valve and spool technology, applied in the direction of valve lift, valve detail, valve device, etc., can solve the problems of no rotation angle detection device, long adjustment time, large flow adjustment range, etc., and achieve simple quantitative relationship and sealing effect Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

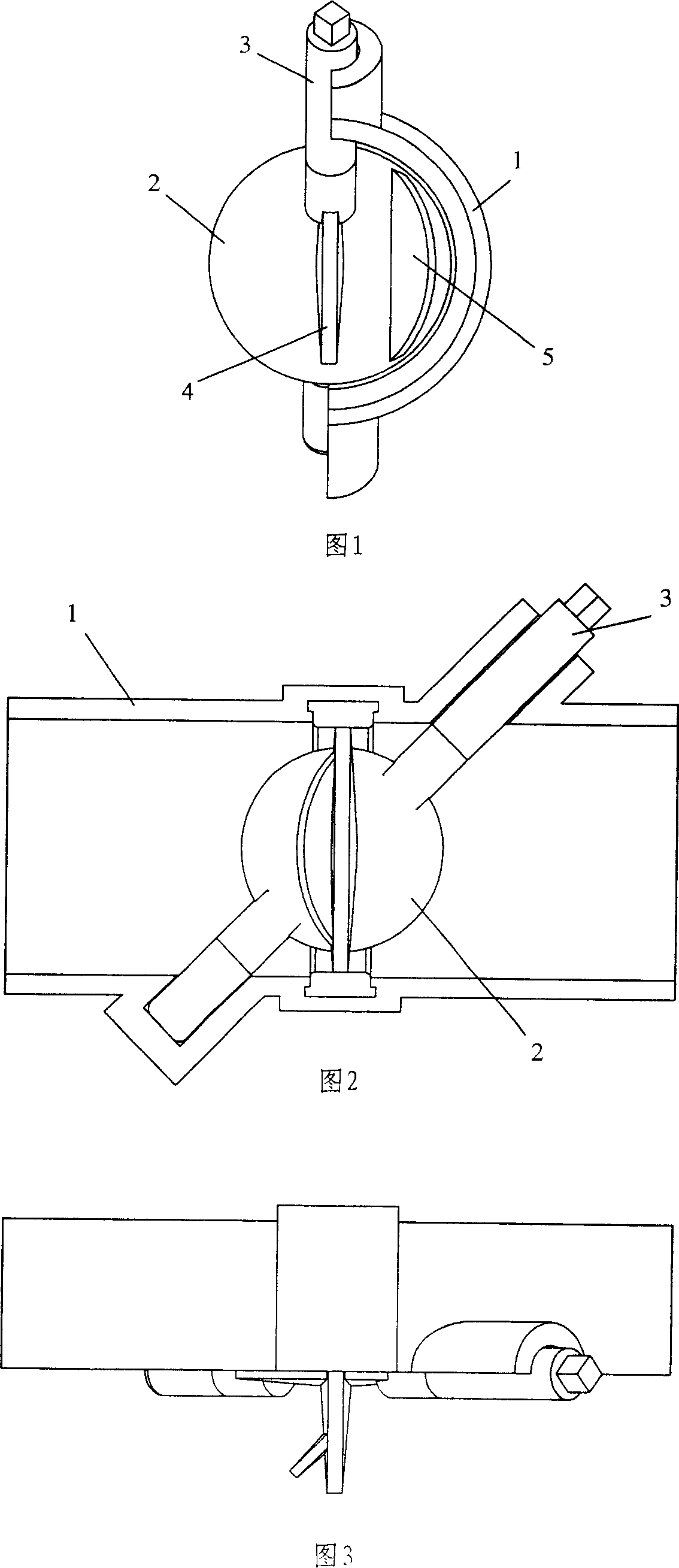

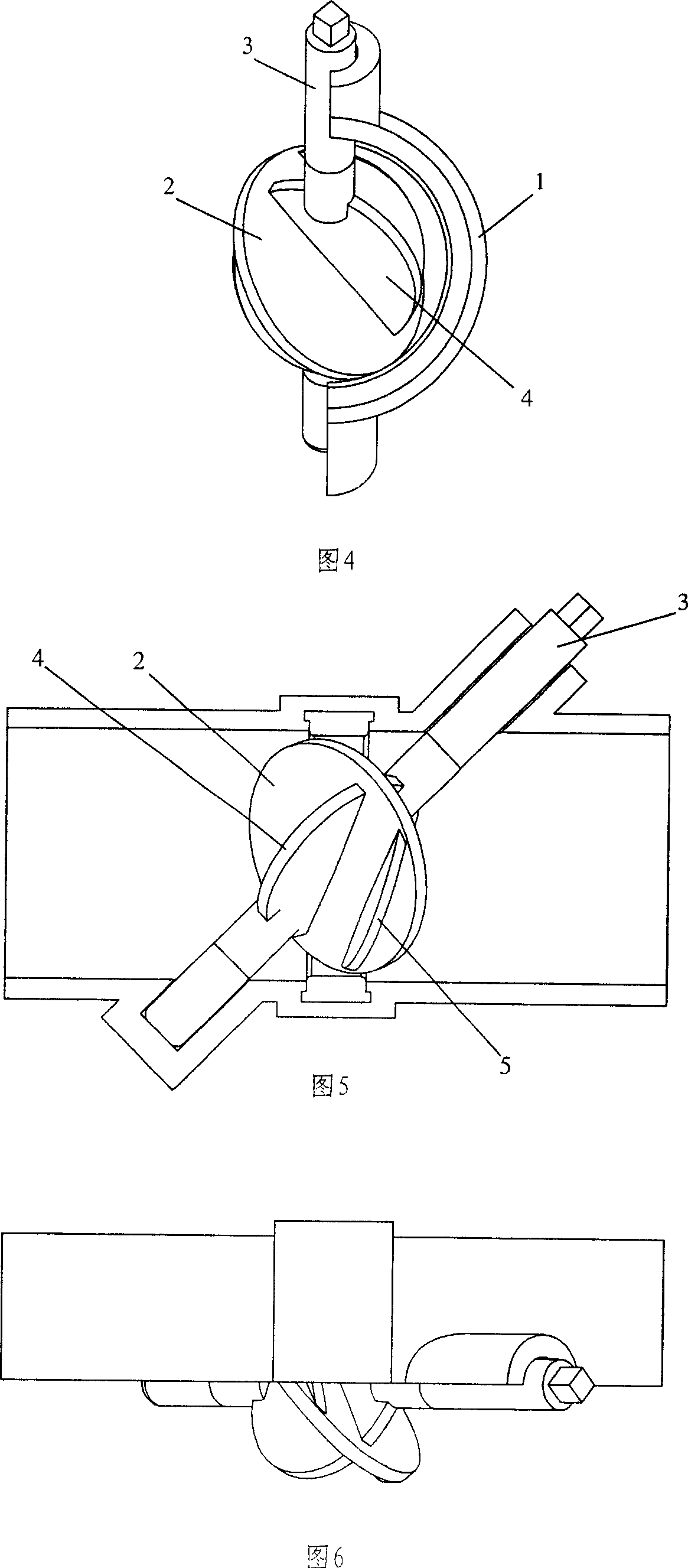

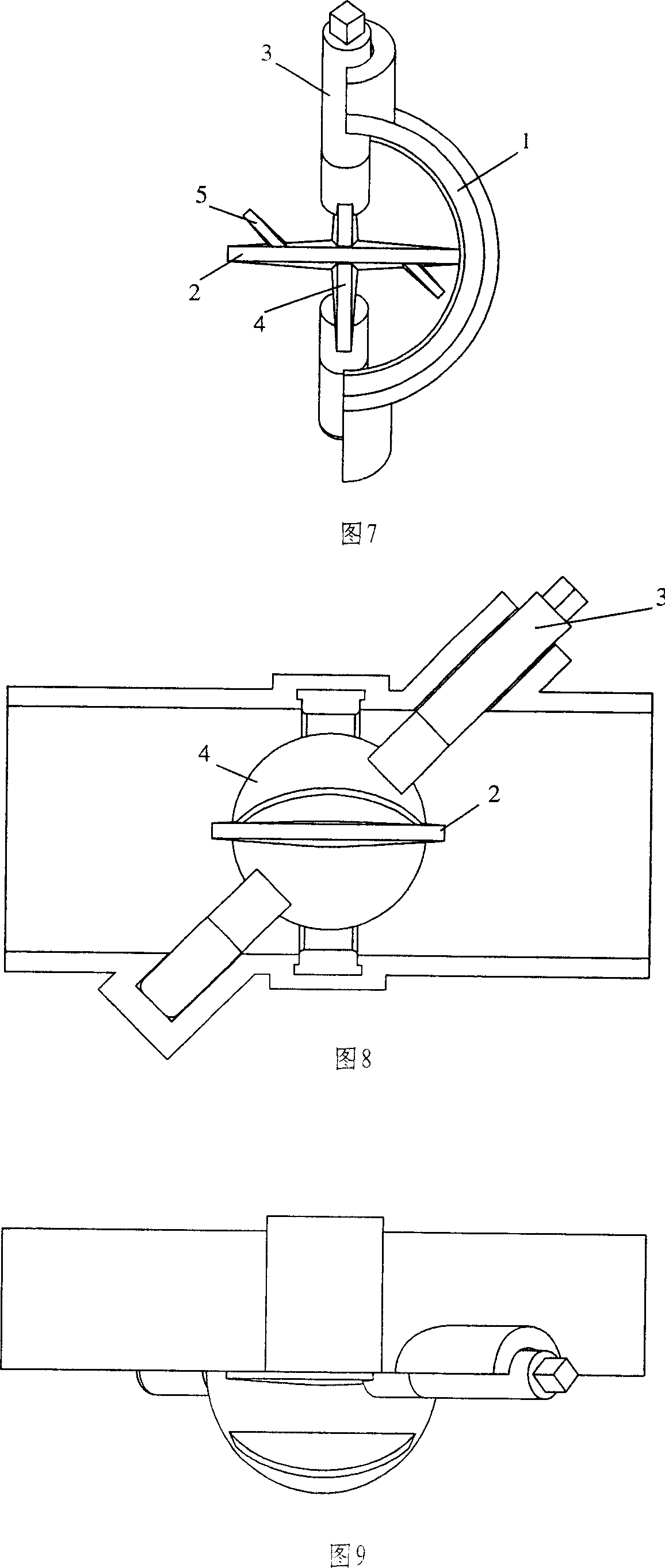

[0030] Such as figure 1 , figure 2 , image 3 Shown are the left view, front view, and top view of the butterfly valve of the present invention in a fully closed state, respectively. The circumference of the valve plate 2 is in close contact with the gasket in the housing 1, and fluid cannot pass through at this moment. In the fully closed state, since the rotating shaft of the butterfly valve plate of the present invention does not pass through the outer edge of the valve plate 2, it will not interfere with the sealing gasket of the valve plate 2, which improves the assembly conditions and stress conditions of the valve plate, so the valve plate of the present invention The sealing performance is obviously better than ordinary butterfly valves.

[0031] The invention changes the position of the rotating shaft of the valve plate in the common butterfly valve. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com