Tuned absorbers for rails

A technology for shock absorbers and rails, which is applied in the directions of rails, fixed rails, roads, etc., and can solve problems such as deterioration of component performance and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

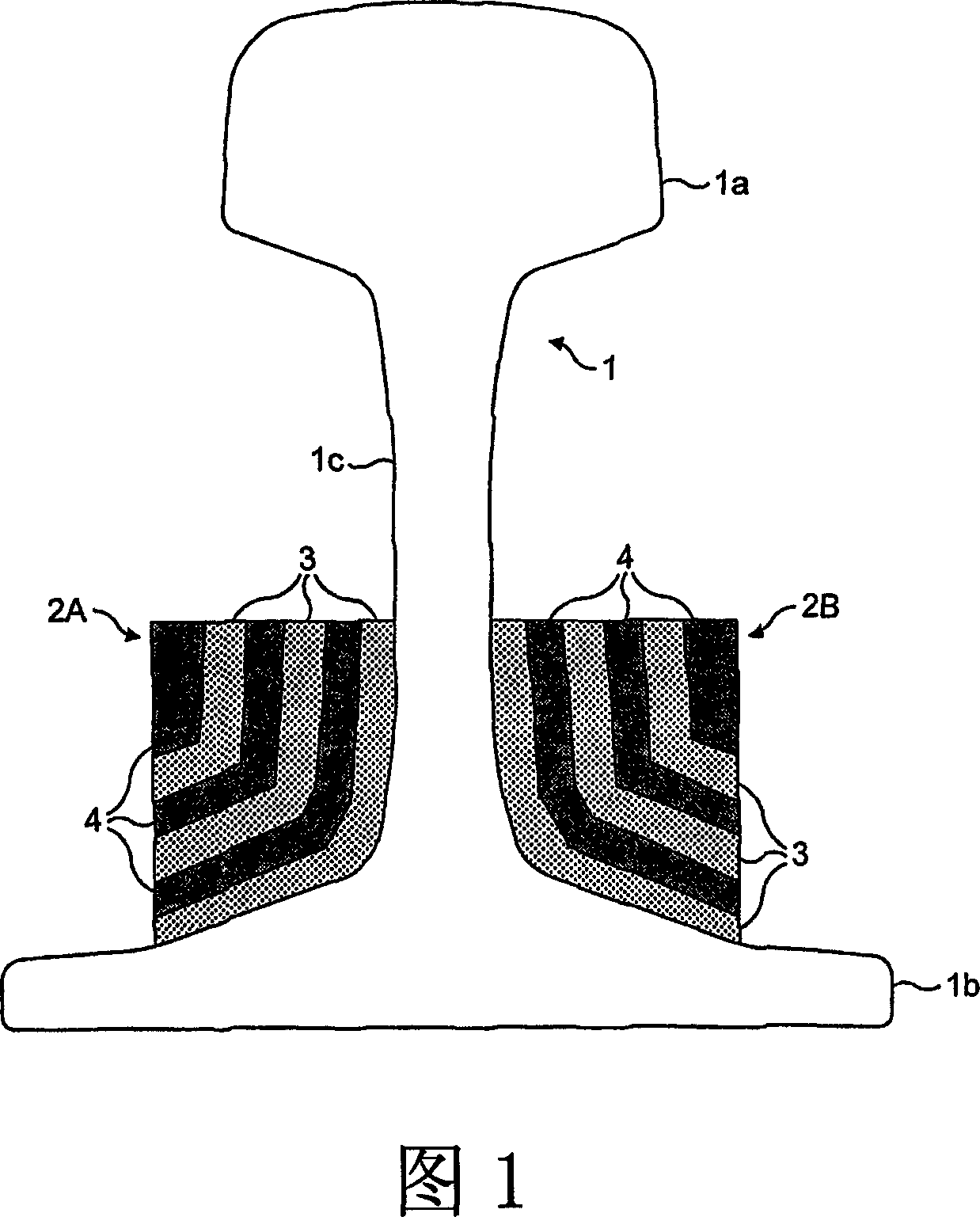

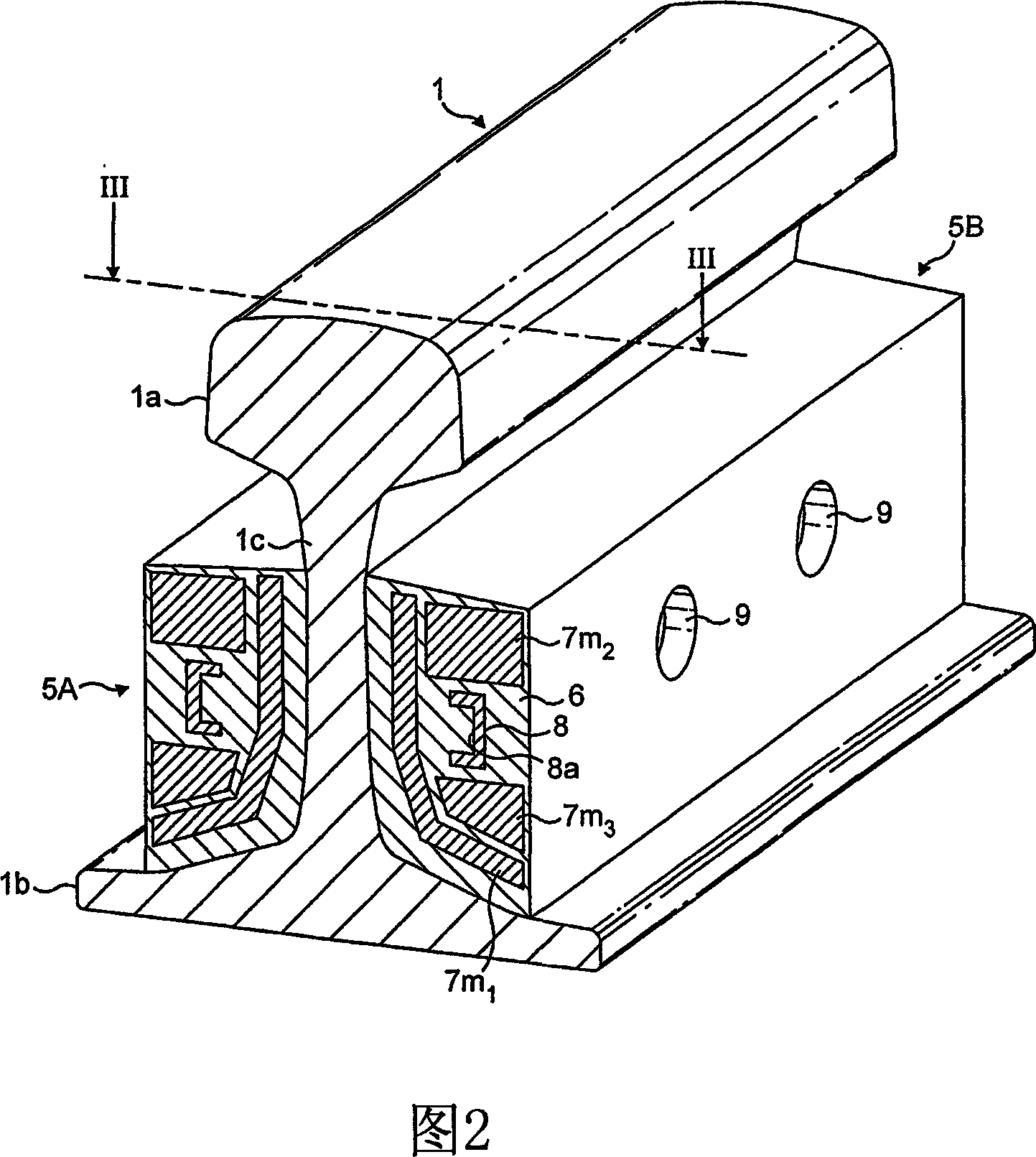

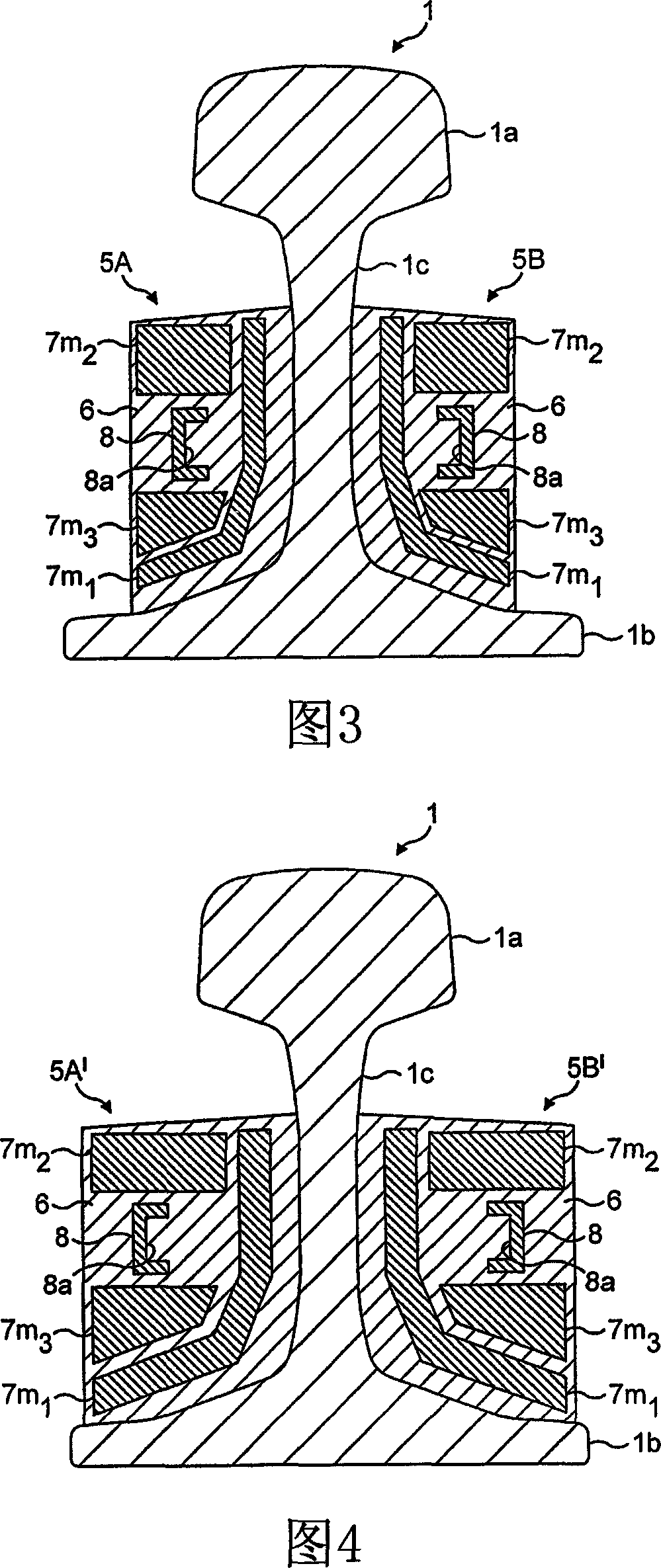

[0053] As a specific embodiment, Fig. 2 and Fig. 3 provide a pair of tuning dampers 5A, 5B installed on the rail 1, the rail head of the rail 1 is 1a, the rail bottom is 1b, and the rail head and the rail bottom are connected Rail waist 1c. The tuned shock absorbers 5A, 5B are placed adjacent to each side of the rail waist 1c as shown in the figure, and on the rail bottom 1b, each tuned shock absorber in 5A, 5B all includes an elastic body 6, and its shape is shown in the figure Shown, so that it fits in the space defined by the rail waist and the rail bottom. The elastic body 6 includes three effective masses 7m1, 7m2, 7m3 and a beam 8. There is a channel 8a on the side of the beam 8 facing the rail waist 1c, and two circular holes 9 are processed on the outer surface of the elastic body 6. They pass through Pass through the elastic body 6 to reach the inner surface, connect with the rail waist 1c, and process corresponding positioning holes (not shown in the figure) at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com