Method and apparatus for micro-droplet spray printing

A micro-droplet and inkjet printing technology, which is applied in printing devices, power transmission devices, printing, etc., can solve problems such as delay in output time, blockage of printing heads, and inability to confirm printing quality in real time, so as to improve flatness and improve operation Efficiency, shortened method time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] According to the micro-droplet printing device and method disclosed in the present invention, the micro-droplet printing device and method referred to herein can be applied to printed circuit boards, but are not limited to printed circuit boards, such as color filters, organic films Transistors, polymer organic light-emitting diodes, biochips and other micro-components that can be produced by micro-droplet printing can also apply the technology disclosed in the present invention.

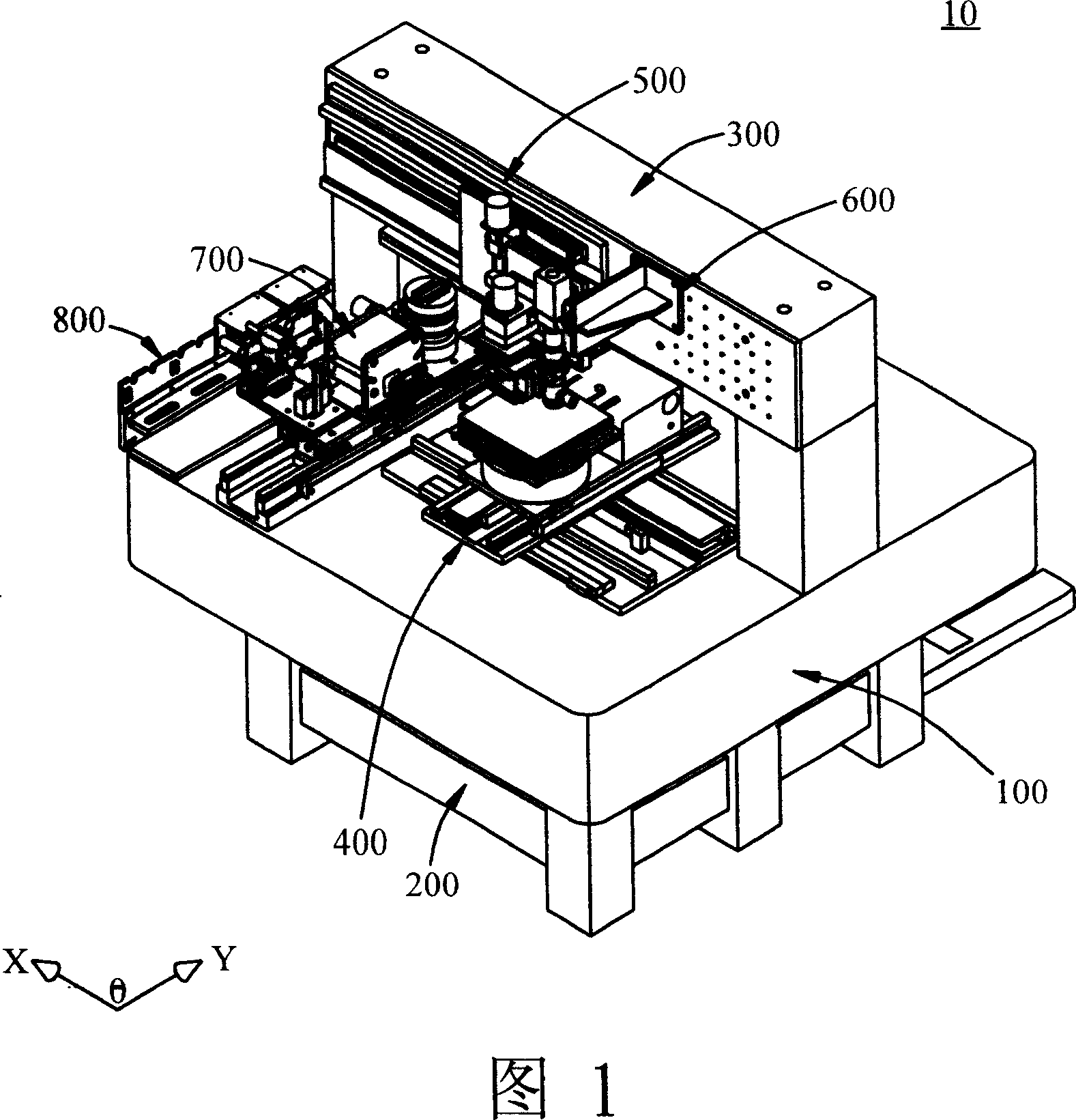

[0106] Please refer to FIG. 1 , which shows a droplet printing device 10 of the present invention, which includes a base 100, a support frame 200, a gantry frame 300, a motion platform module 400, a printing module 500, and an image detection module. 600, the print head maintenance module 700, and the print head storage module 800, so as to jointly achieve the purpose of the micro droplet printing.

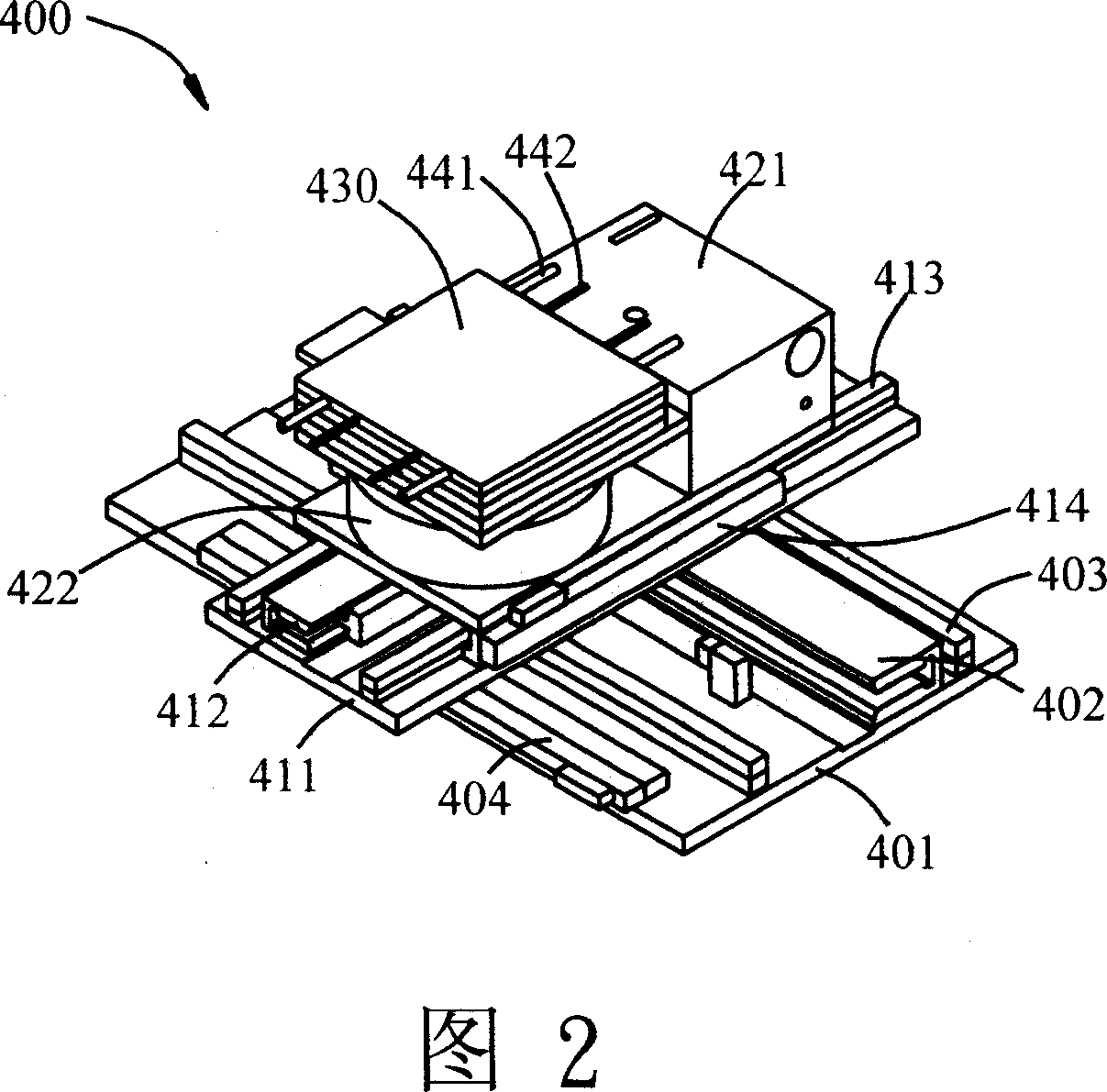

[0107] Please refer to FIG. 2 , the moving platform module 400 is shown in the figure. Under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com